Tube bundle type dedusting and demisting device with liquid collection function

A technology for demisting device and liquid collection, which is applied in the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of inability to meet the discharge index, multi-processing stages, affecting the processing effect, etc., and achieves high reliability, The effect of high efficiency and low resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

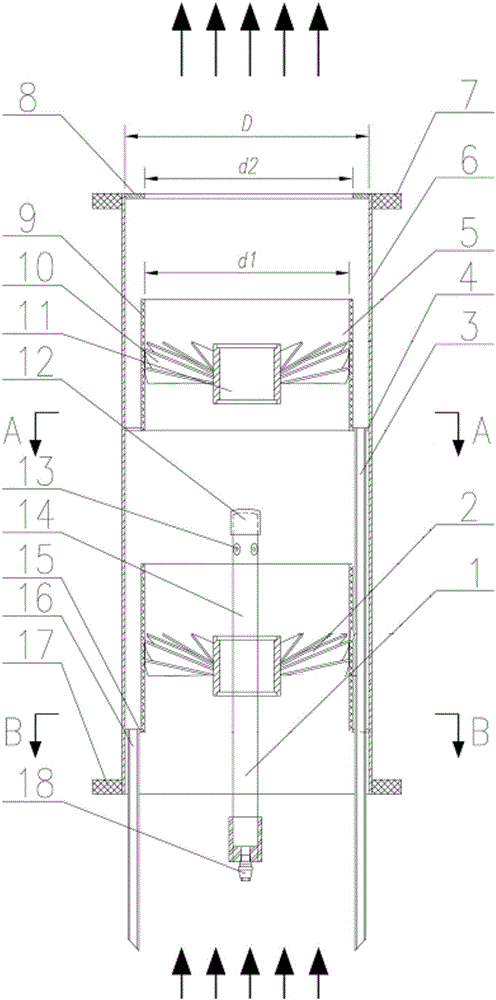

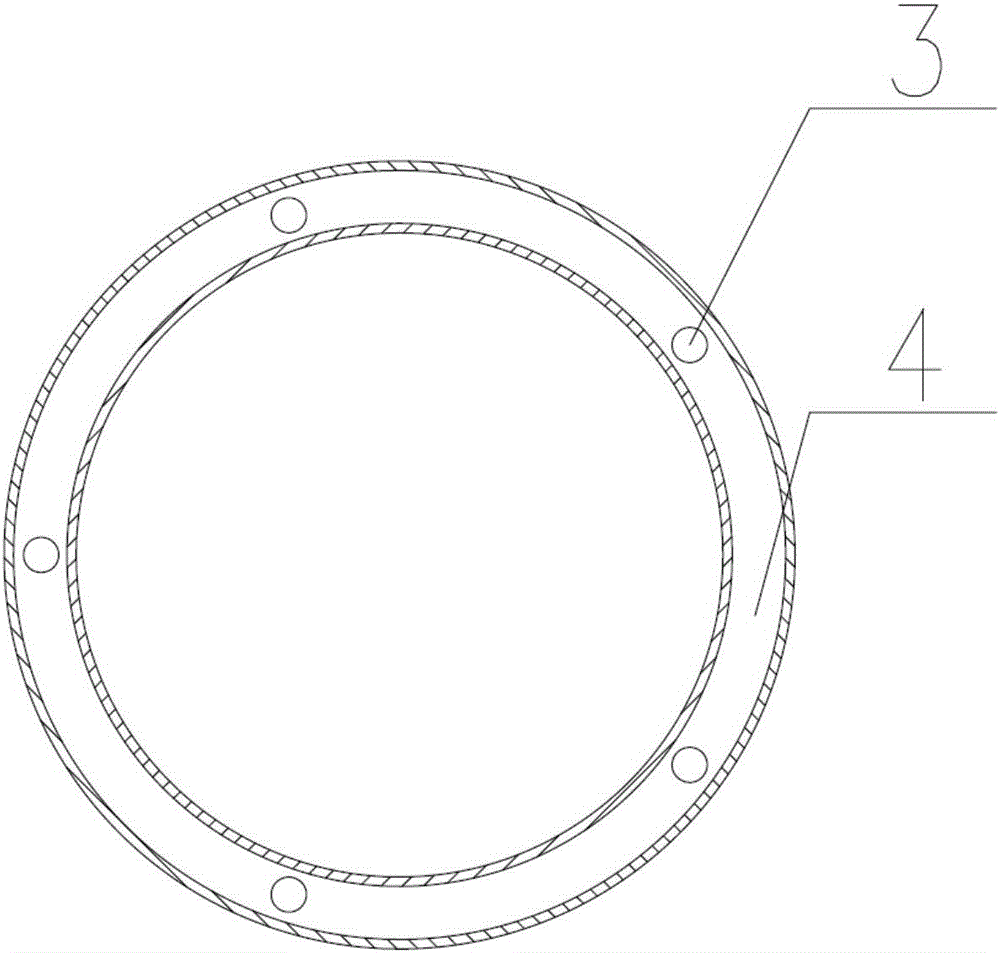

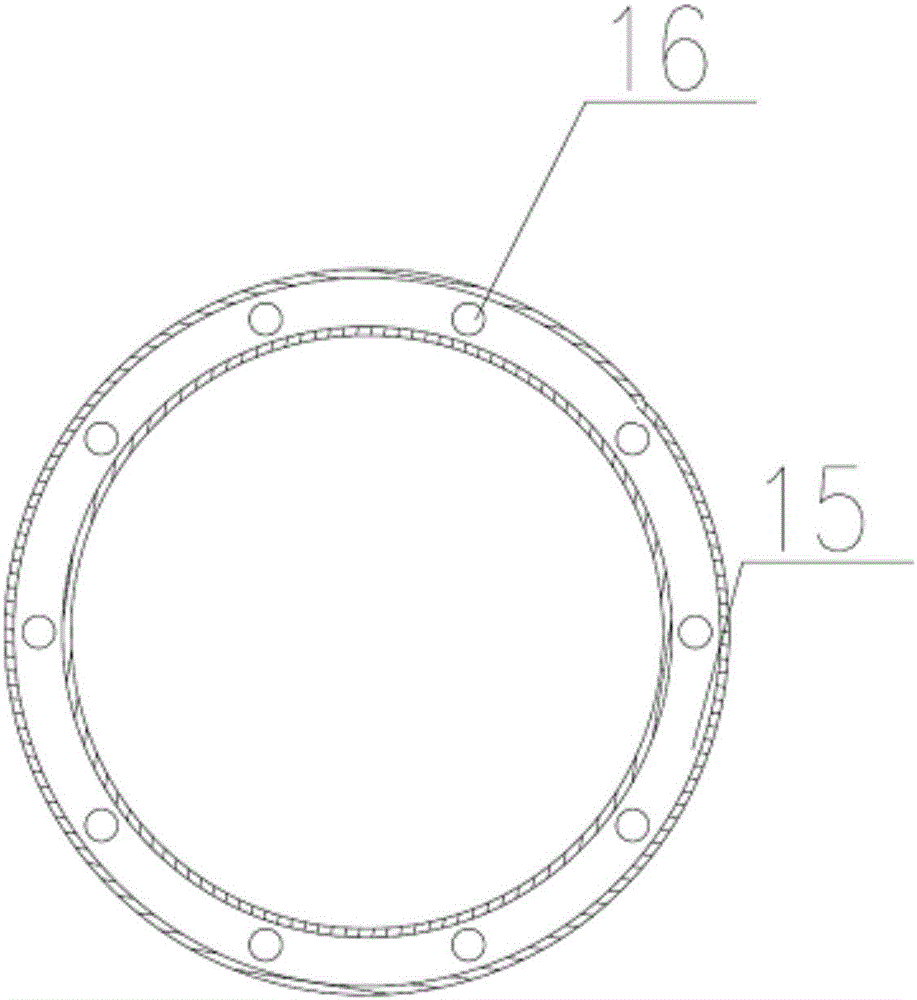

[0029] like Figure 1~3 , a tube-bundle type dedusting and mist removal device with liquid collection, the device includes n tube-bundle type dust-removal and mist-removal units, n≥1; the tube-bundle type dust-removal and mist-removal unit includes a demisting unit cylinder (6), There are 2 swirl components and 2 cylindrical outer cylinders (9) (i takes the value of 1) inside the demisting unit cylinder (6), and the one above the demisting unit cylinder (6) is the first Secondary swirl assembly (5), in the annular area between the cylinder body (6) of the demister unit (6) and the cylindrical outer cylinder (9) of the second-stage swirl assembly (5), a first-stage holding Liquid ring (4), the first-stage liquid-holding ring (4) is provided with a number of drain pipes; the first-stage swirl component (15) is located under the demisting unit cylinder (6). A first-stage liquid holding ring (15) is provided in the annular area between the cylinder body (6) of the demister unit (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com