Composite magnetic adsorption visual detection climbing robot

A wall-climbing robot, video detection technology, applied in the direction of motor vehicles, transportation and packaging, can solve the problems of increasing the installation space of the motor, poor comprehensive performance, poor movement flexibility, etc. , the effect of strong load capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

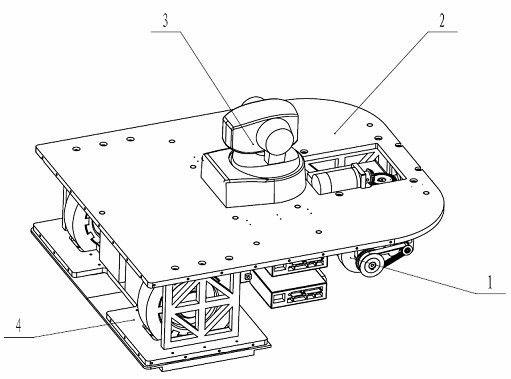

[0041] A composite magnetic adsorption type video detection wall-climbing robot includes a vehicle frame, a front wheel module and a rear wheel module installed at both ends of the vehicle frame, a video detection platform is installed on the vehicle frame, and the composite magnetic adsorption type video detection wall-climbing robot It has a three-wheel structure, and the three wheels are all driving wheels. The front wheel module adopts a drive-steering integrated magnetic wheel, and the rear wheel module adopts a permanent magnet gap adsorption structure. The permanent magnet, the two rear wheels passing through the chassis, the reducer that drives the wheel, and the DC motor that drives the reducer. The front wheel module adopts a drive-steering integrated magnetic wheel. The front wheel of the front wheel module is a magnetic wheel, and the steering is controlled; The chassis of the rear wheel module is equipped with a permanent magnet gap adsorption device. The two rear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com