Assembling device for pump core combination part of fuel pump and method for assembling pump core combination part through assembling device

An assembly device and assembly technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems that cannot prevent defective filter screens from being mixed into the assembly line, high labor intensity, and insecure air pressure, etc., to achieve quality assurance , reduce labor intensity, and exert pressure accurately and reliably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

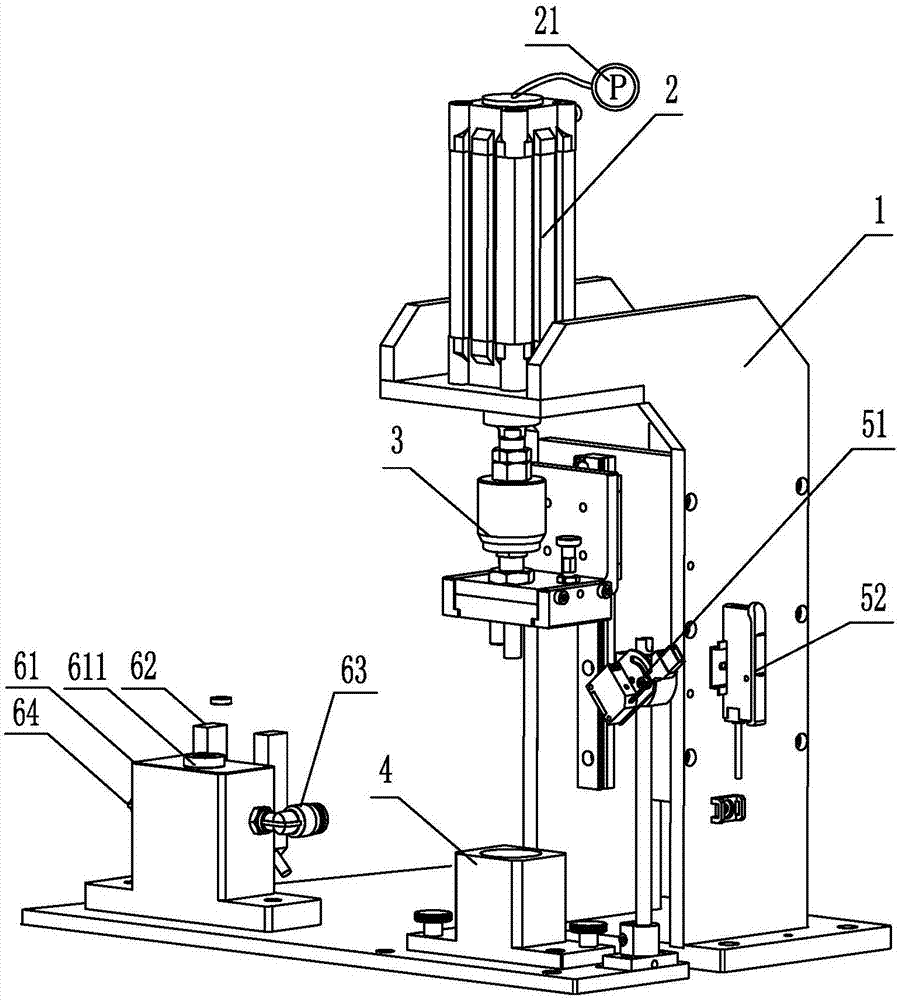

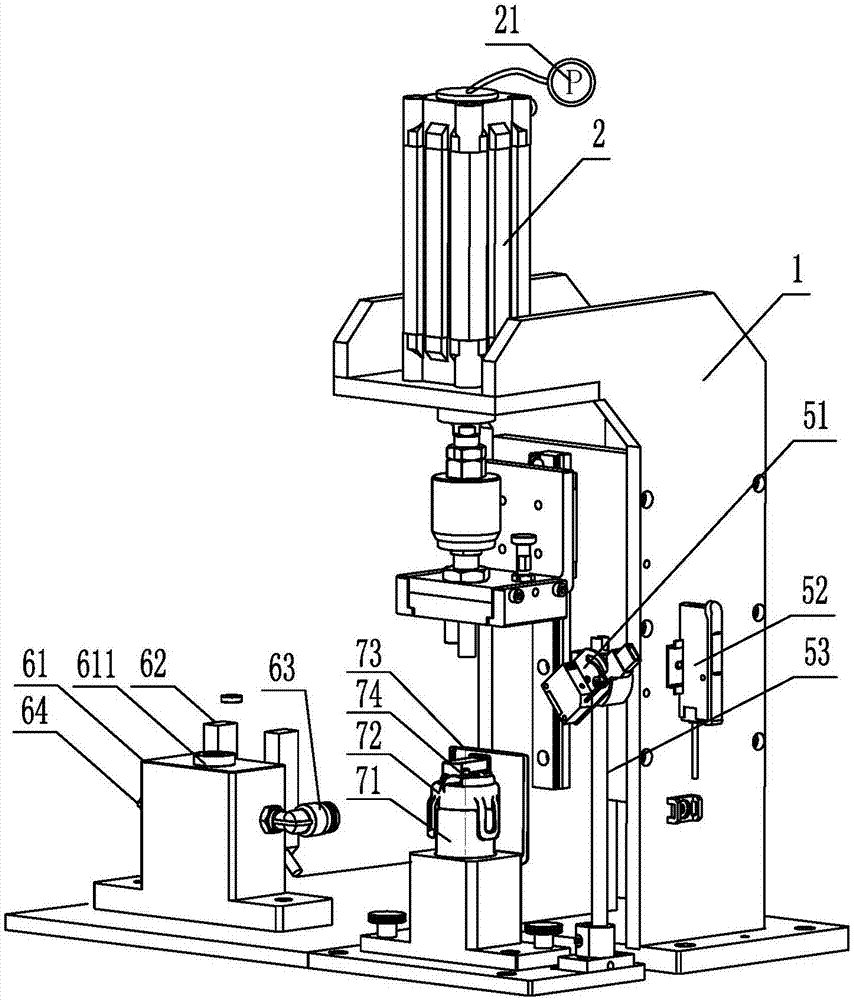

[0051] An assembly device for a fuel pump core assembly, comprising a base 1, a pump core positioning seat 4 for fixing the pump core assembly, a compression device 3 for compressing the filter screen and the pressing sheet, and a compression device A cylinder assembly 2 that provides power, the cylinder assembly 2 is supplied with compressed air from an external air source and controlled by an external control unit circuit;

[0052] The pump core positioning seat 4 is installed at the bottom of the base, and the pressing device 3 is installed at the waist of the base and is connected with the cylinder assembly 2 at the top of the base. The centers of the cylinder assembly, the pressing device and the pump core positioning seat are at the same on the vertical centerline;

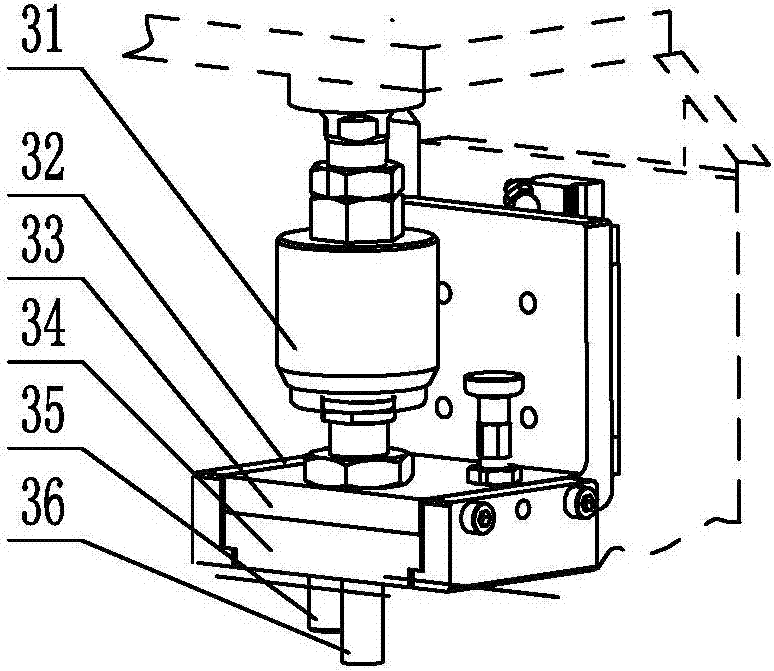

[0053]The pressing device 3 includes a universal joint 31, a type changing plate 34, a filter press head 35 and a tablet pressing head 36. The type changing plate 34 is slidably installed in the type changin...

Embodiment 2

[0058] A method for assembling a fuel pump core assembly, said method is a method for assembling an automobile fuel pump core assembly with the fuel pump pump core assembly assembly device described in Embodiment 1, comprising the following steps:

[0059] S1. Re-inspect the purification quality of the filter: place the interface 711 of the filter on the blowing port 611 of the blowing base 61, after the photoelectric switch senses that the workpiece is placed, under the control of the external control unit, it will automatically press the set button. The number of times of blowing and blowing and the time interval of blowing and blowing are blown and sucked to test the filter screen;

[0060] S2. Install the lower bracket into the bottom of the fuel pump core, place the bottom of the fuel pump core with the lower bracket up in the pump core positioning seat 4, and fix it;

[0061] S3. Fasten the qualified filter screen on the bottom of the pump core, and connect the interf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com