Transitional track planning method for welding robot

A welding robot and trajectory planning technology, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of not considering the error of the transition section, not considering the transition problem, difficult to quickly switch between different trajectories, etc., to achieve reduction Effects of wear, easy tracking, and low energy consumption

Inactive Publication Date: 2011-06-15

CHANGSHA HONGDIAN AUTOMATION TECH

View PDF4 Cites 27 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The above trajectory planning methods have not studied the switching and transition between different trajectories, so it is difficult for the robot to quickly switch to different trajectories to work during the welding process. The transition between different trajectories is a hot spot and difficulty in robot trajectory planning. The problem is that the direct error between the transition section and the ideal trajectory is not considered in the prior art, but these errors may be key parameters in some applications, such as robotic arc welding

The transition between straight lines and other shapes (such as arcs) is not considered

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

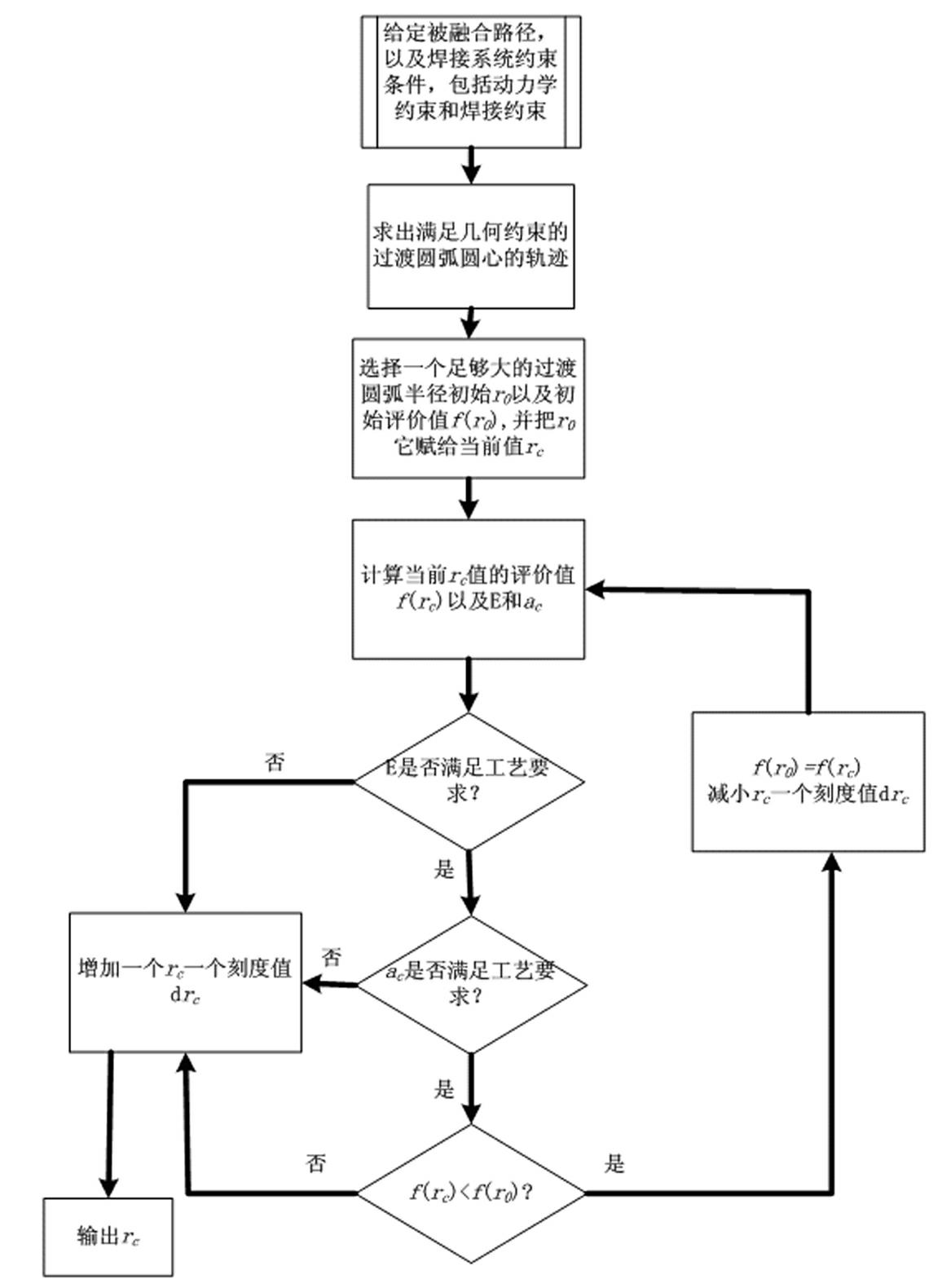

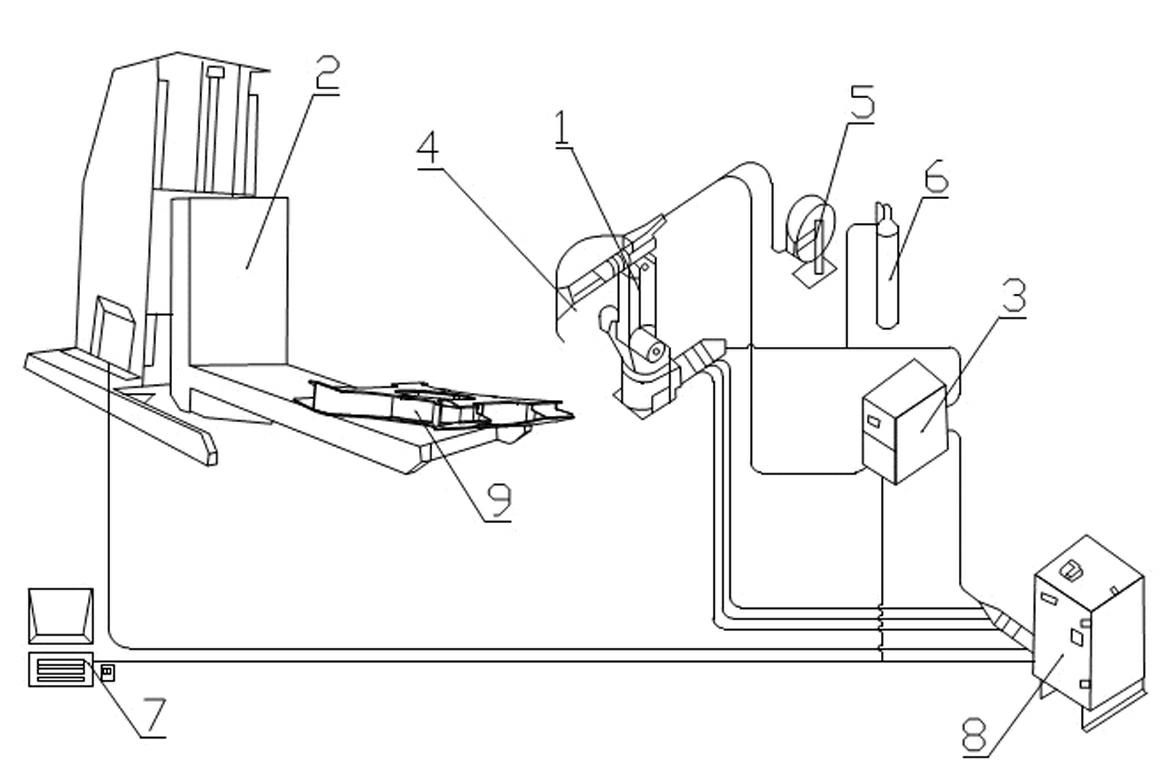

The invention discloses a transitional track planning method for a welding robot. The transitional track is used for fusing a straight segment welding line and an arc segment welding line, geometric constraint conditions of adjacent fused straight segment welding line and fused arc segment welding line of a workpiece to be welded are imported into a robot path planning module to generate a transitional segment arc welding line track, and by controlling the arc radius of the transitional segment track, welding constraint conditions and robot welding system dynamic constraint conditions are metwhen the robot welds the transitional segment. The track planning method is suitable for switching different segments of tracks and planning transitional tracks, and solves the problem of smoothness of transiting from the straight segment welding line to the arc segment welding line when the robot performs arc welding.

Description

A Welding Robot Transition Trajectory Planning Method technical field The invention relates to a robot transition trajectory planning method, in particular to a welding robot trajectory planning method. Background technique With the development of advanced manufacturing technology, it has become an inevitable trend to realize the automation, flexibility and intelligence of welding product manufacturing. The trajectory planning of the robot is usually completed in the Cartesian coordinate system, because the tasks of the robot are usually completed in the task space, and the realization of the barrier function is easier, but the trajectory planning of the robot is usually realized in the joint space , after the geometric trajectory of the robot is generated in the Cartesian coordinate system, it is converted into the joint trajectory in the key space of the robot through inverse kinematics calculation. At present, there are some studies on the trajectory planning method o...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B23K31/02

Inventor 汤哲张立彭浩明陈华荣周建勇

Owner CHANGSHA HONGDIAN AUTOMATION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com