Path planning method for complicated-shape workpiece of robot bead weld based on radial bias

A trajectory planning and robot technology, applied in the direction of manufacturing tools, welding equipment, arc welding equipment, etc., can solve the problems of reducing production efficiency, affecting the quality of surfacing welding, increasing labor hours, etc., to achieve improved use efficiency, broad application prospects, good The effect of the surfacing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The invention will be further described in conjunction with the accompanying drawings.

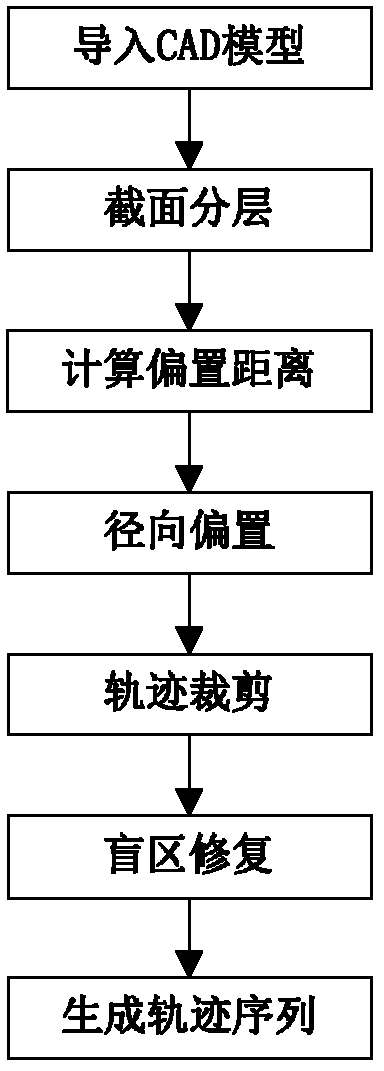

[0030] The main process of this method is as referenced figure 1 As shown, it mainly includes the following steps:

[0031] (1) Import the CAD graphics file of the workpiece;

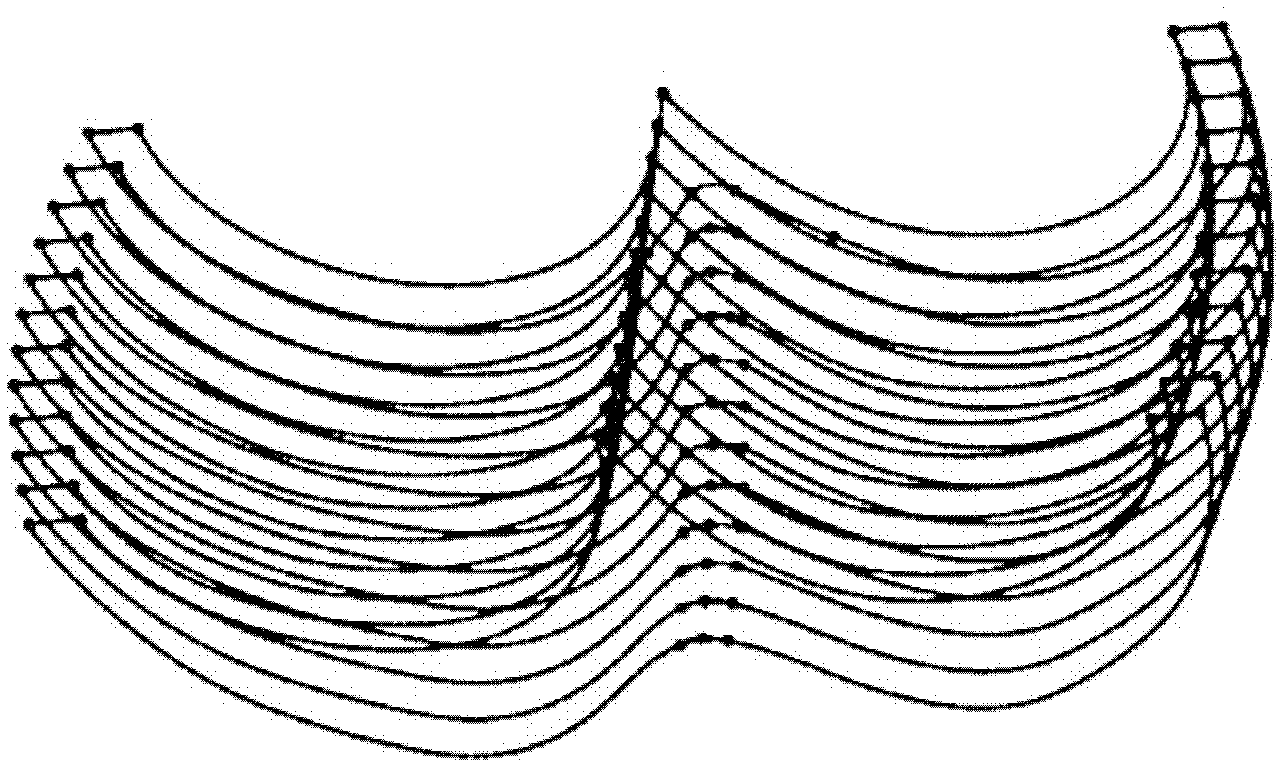

[0032] (2) Perform cross-section layering on the 3D CAD graphics of the workpiece, obtain the cross-section contour line, and generate a cross-section sketch containing the contour line, such as image 3 shown;

[0033] (3) On each section, according to the width of the weld bead and the boundary line of the workpiece ( Figure 4 The lengths of the line segments A1 to M and A2 to N are the boundary lines) to automatically calculate the radial offset distance: first divide the length of the left boundary line by the default weld bead width, and determine the offset distance by rounding up. The offset distance is The width of the weld bead is realized by automatically adjusting the welding parameters (weldi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com