Device and method for visual detection of welding quality of robot

A visual inspection device and robot welding technology, applied in welding accessories, manipulators, manufacturing tools, etc., can solve problems such as a large number of auxiliary equipment investment, and achieve the effect of saving auxiliary equipment investment, intuitive appearance and rich information.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

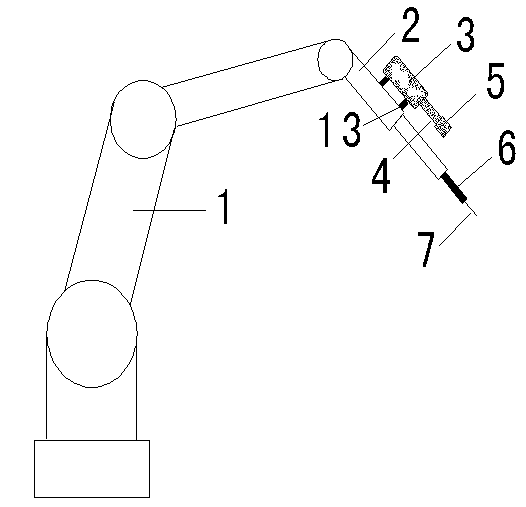

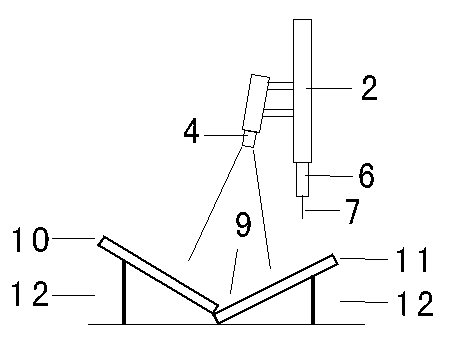

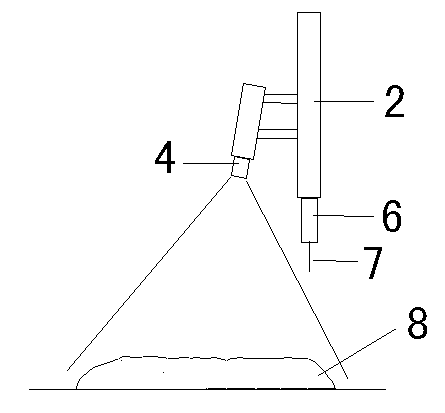

[0024] Such as figure 1 As shown, a robot welding quality visual inspection device of the present invention includes a welding torch head 6 connected to the welding arm 2 of the robot 1, a vision gun 4 and a vision system, and the vision gun 4 is connected to the welding arm 2 to follow the welding torch The head 6 moves, observes the welding point and transmits the scanned picture information to the vision system; the vision system compares the received picture information with the standard formula data, and checks the splicing error of the weldment before welding and the weldment after welding. Real-time detection and judgment of point quality and welding process.

[0025] The vision gun 4 is connected to the welding arm 2 by an adjustable support 13 .

[0026] A method for visual inspection of robot welding quality of the present invention, comprising steps:

[0027] 1. Steps for establishing the standard recipe data for splicing error detection: splice the samples accord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com