Down products with penetration resistance and manufacturing method thereof and manufacturing method of down jacket

A production method and anti-drill down technology, which are applied in the field of down processing, can solve the problems of inability to effectively realize anti-drill down, anti-down paper pores or even breakage, low strength, etc., and achieve the effect of realizing the function of anti-drill down.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

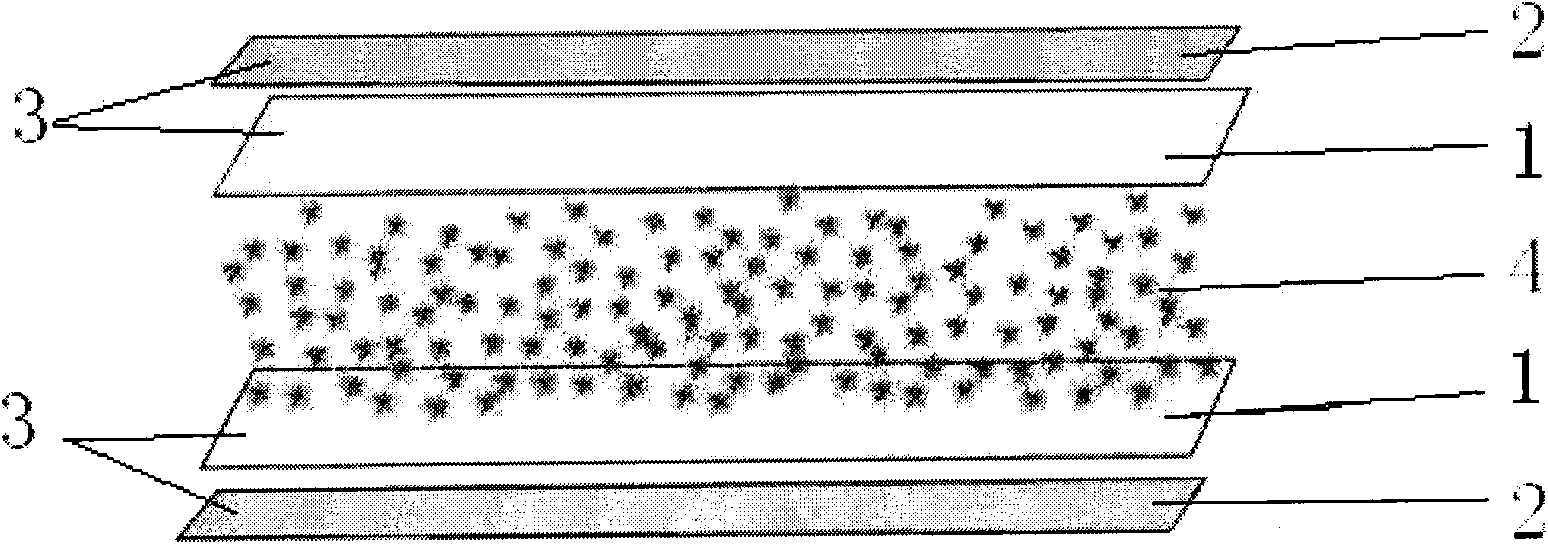

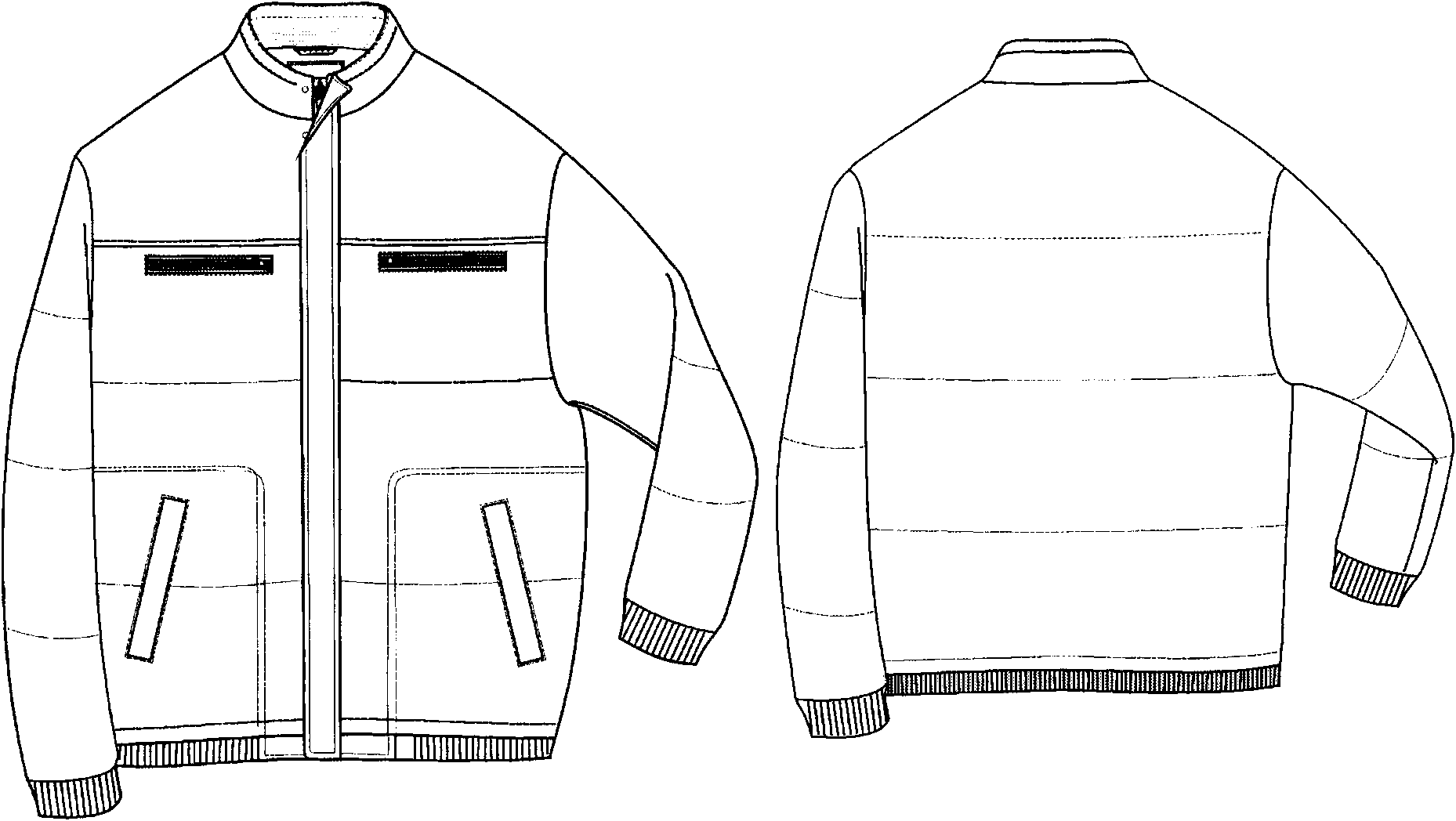

[0032] The invention proposes a method for making anti-drilling down products, the core idea of which is: cutting polyester cloth and non-adhesive non-woven interlining; sewing the polyester cloth and non-adhesive non-woven interlining together to form polyester cloth and non-adhesive non-woven lining The bag-like combination of lining; fill the bag-like combination of polyester cloth and non-adhesive non-woven lining with down, and completely sew the bag-like combination of polyester cloth and non-adhesive non-woven lining to make anti-drilling down products. In the anti-drilling down product, the polyester cloth completely wraps the down, and is located between the down and the non-adhesive non-woven interlining, and the non-adhesive non-woven interlining completely wraps the polyester cloth.

[0033] The down-drilling-proof down product provided by the invention can effectively realize the down-drilling-proof function.

[0034] In order to make the object, technical solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com