Cold-defending insulating composite material and preparation method and application thereof

A composite material and mixture technology, which is applied in the field of composite materials, can solve the problems of general cold protection and heat preservation, high cost, uncomfortable wearing, etc., and achieves the effects of excellent cold protection and heat preservation performance, strong industrial value, and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

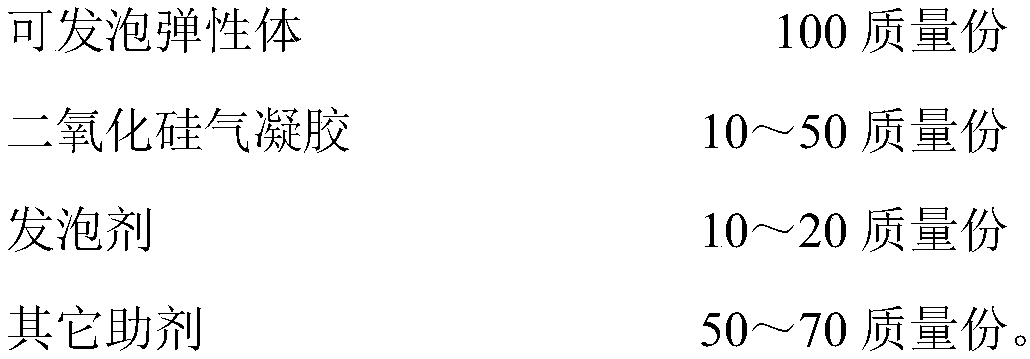

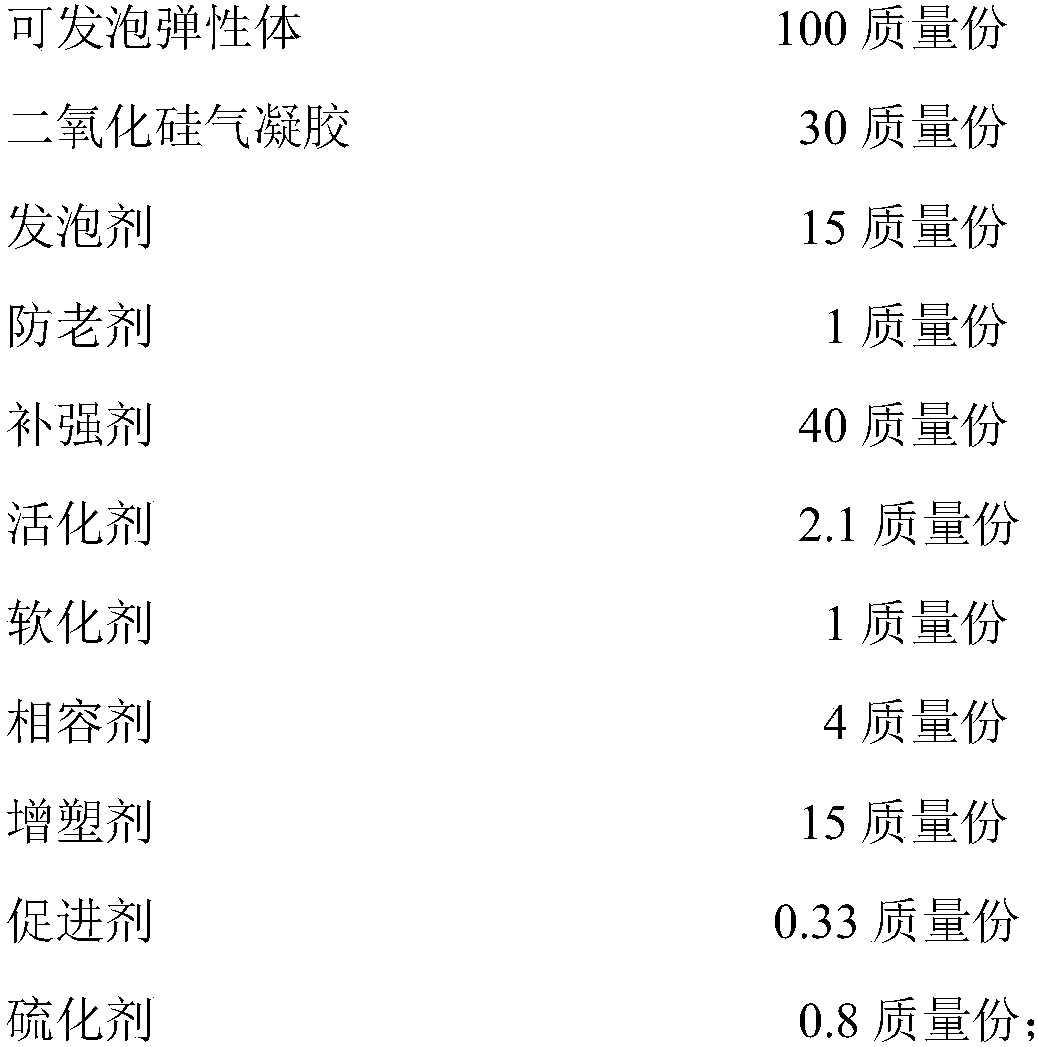

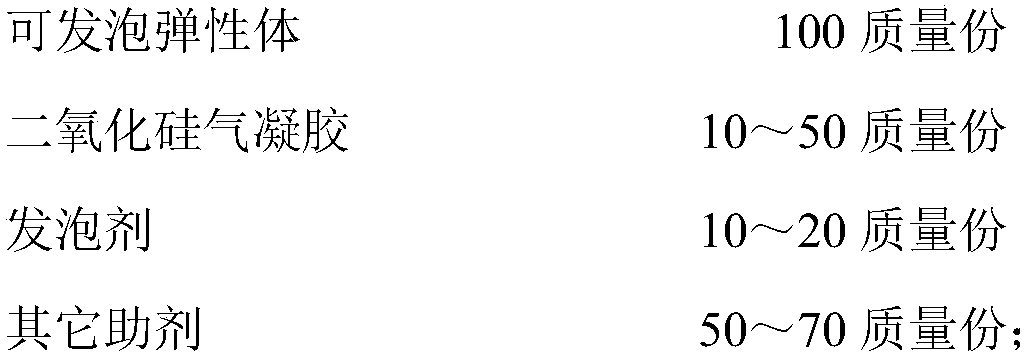

[0024] 1. Formula composition:

[0025]

[0026] In this embodiment:

[0027] The foamable elastomer is a mixture composed of 80 parts by mass of nitrile rubber (NBR), 15 parts by mass of polyvinyl chloride (PVC) and 5 parts by mass of butadiene rubber (BR);

[0028] The silica aerogel is a silica aerogel powder with a 3D three-dimensional network structure and a particle diameter of 20-50 nanometers, which is prepared by a normal temperature and normal pressure process;

[0029] The foaming agent is DDL105;

[0030] The antioxidant is rubber antioxidant 4020 (6PPD), and its chemical name is: N-(1,3-dimethylbutyl)-N'-phenyl-p-phenylenediamine;

[0031] The reinforcing agent is calcium carbonate;

[0032] The activator is zinc oxide;

[0033] Stearic acid is selected as the softening agent;

[0034] The compatibilizer is maleic anhydride;

[0035] The plasticizer is plasticizer DOP, and its chemical name is dioctyl phthalate;

[0036] The accelerator is a complex of 0.25 parts by mass of accel...

Embodiment 2

[0048] The difference between this example and Example 1 is only that: 100 parts by mass of the foamable elastomer in the formula is composed of 95 parts by mass of EPDM and 5 parts by mass of butadiene rubber (BR ), the amount of silica aerogel is 40 parts by mass; the rest of the content is the same as that described in Example 1.

[0049] After testing, the properties of the composite material prepared in this example are as follows:

[0050] Test items

Embodiment 3

[0052] The difference between this example and Example 1 is only that: 100 parts by mass of the foamable elastomer in the formula composition is composed of 90 parts by mass of thermoplastic elastomer (TPE) and 10 parts by mass of butadiene rubber (BR) The amount of silica aerogel is 20 parts by mass; the rest of the content is the same as described in Example 1.

[0053] After testing, the properties of the composite material prepared in this example are as follows:

[0054] Test items

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com