A cold-proof and warm-keeping composite material and its preparation method and application

A technology of composite materials and formulations, which is applied in the field of composite materials, can solve the problems of general cold-proof and warm-keeping effects, high cost, uncomfortable wearing, etc., and achieve the effect of excellent cold-proof and warm-keeping performance, strong industrial value and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

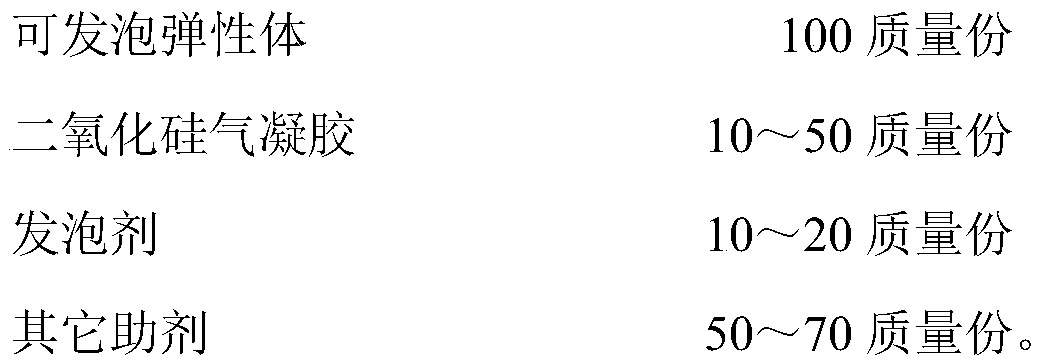

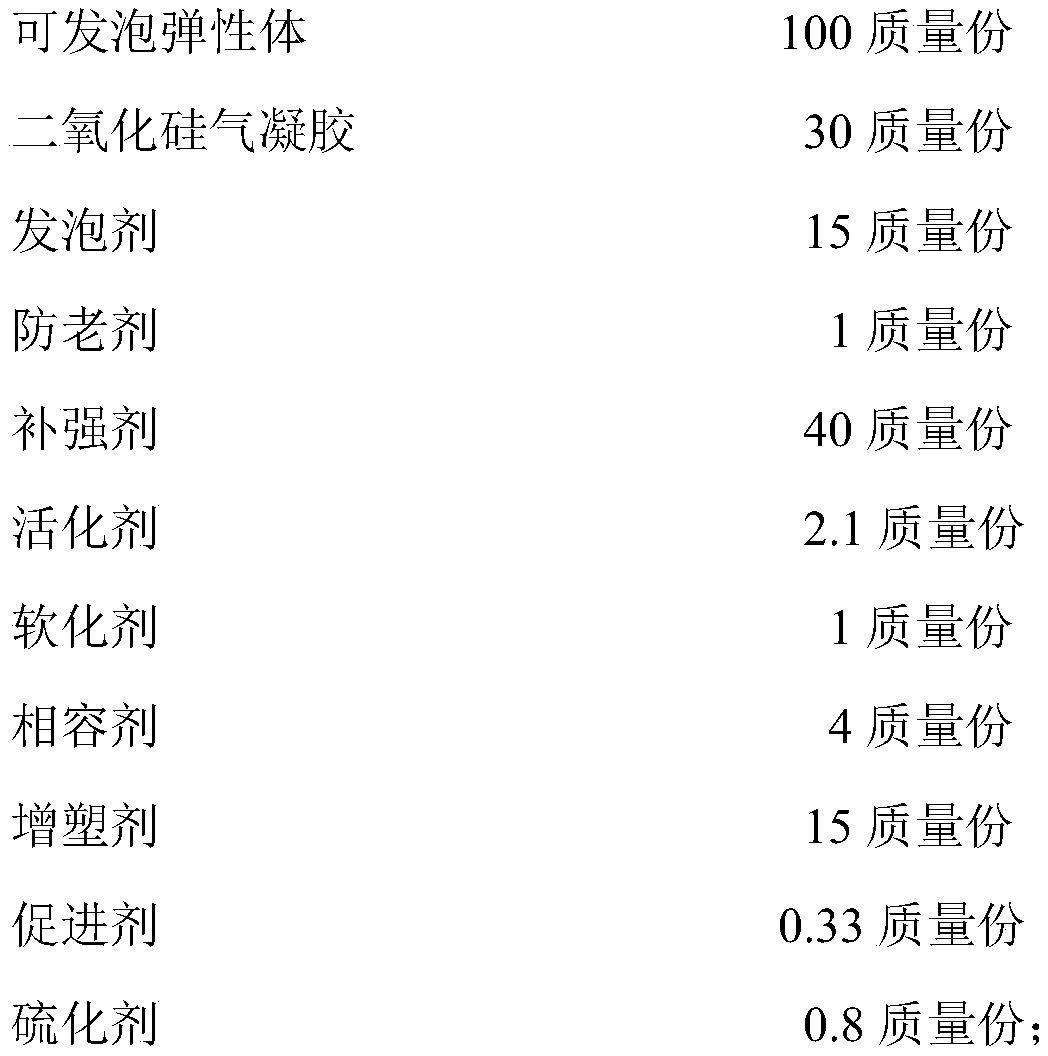

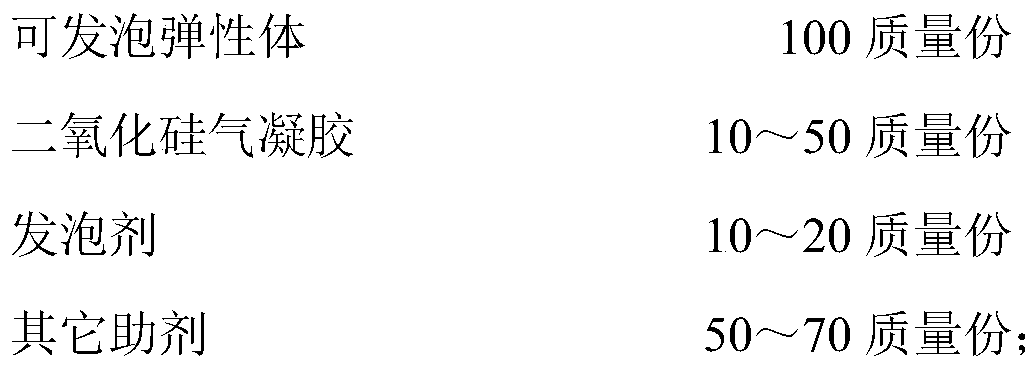

[0024] 1. Formula composition:

[0025]

[0026] In this example:

[0027] The foamable elastomer is a mixture of 80 parts by mass of nitrile rubber (NBR) and 15 parts by mass of polyvinyl chloride (PVC) and 5 parts by mass of butadiene rubber (BR);

[0028] The silica airgel is a silica airgel powder with a 3D three-dimensional network structure and a particle diameter ranging from 20 to 50 nanometers, which is prepared by a normal temperature and pressure process;

[0029] What described foaming agent selects for use is foaming agent DDL105;

[0030] What described anti-aging agent selects for use is rubber anti-aging agent 4020 (6PPD), and chemical name is: N-(1,3-dimethylbutyl)-N'-phenyl-p-phenylenediamine;

[0031] What described reinforcing agent selects for use is calcium carbonate;

[0032] What described activator selects for use is zinc oxide;

[0033] What described softening agent was selected for use is stearic acid;

[0034] Described compatibilizer selec...

Embodiment 2

[0048] The difference between this embodiment and Example 1 is that 100 parts by mass of the foamable elastomer in the formula composition is made of 95 parts by mass of ethylene propylene diene rubber (EPDM) and 5 parts by mass of butadiene rubber (BR ) composition, the consumption of silica airgel is 40 parts by mass; All the other contents are the same as described in Example 1.

[0049] After testing, the properties of the composite material prepared in this embodiment are as follows:

[0050] Test items Compression Cold Resistance Coefficient (-30℃) Thermal conductivity W / (m·K) Mooney viscosity Shore A Hardness Test Data 0.24 0.039 14.3 16

Embodiment 3

[0052] The only difference between this embodiment and Example 1 is that 100 parts by mass of the foamable elastomer in the formula composition is composed of 90 parts by mass of thermoplastic elastomer (TPE) and 10 parts by mass of butadiene rubber (BR) The mixture, the consumption of silica airgel is 20 parts by mass; All the other contents are the same as described in Example 1.

[0053] After testing, the properties of the composite material prepared in this embodiment are as follows:

[0054] Test items Compression Cold Resistance Coefficient (-30℃) Thermal conductivity W / (m·K) Mooney viscosity Shore A Hardness Test Data 0.31 0.031 25.8 20

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com