A production process of plush flakes

A production process, plush technology, applied in textiles, papermaking, non-woven fabrics, etc., can solve the problems of human skin allergy, microbial residues, easy to produce peculiar smell, etc., achieve good sterilization and deodorization function, stable chemical performance, sterilization strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

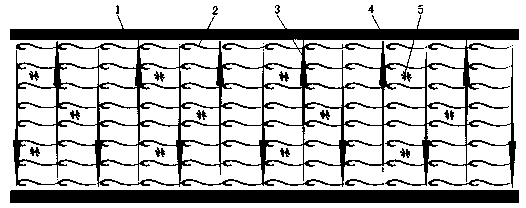

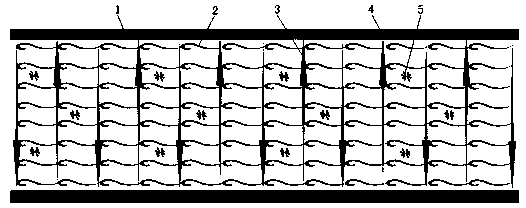

Image

Examples

Embodiment Construction

[0022] The technical solutions in the embodiments of the present invention will be clearly and completely described below. Obviously, the described embodiments are only some of the embodiments of the present invention, but not all of them.

[0023] In this experiment, two 250-type single-cylinder double-guided carding machines and a three-wire cross-lapper were used, plus the main needling pre-needling machine and a digital oven to form a production line. The two carding machines use different raw material formulas and undertake different carding functions. The ingredients are as follows for 100 kg of raw materials:

[0024] Step 1: Ingredients

[0025] A carding machine ingredients: Group A: 8 kg of low-melting fiber, 2 kg of camel hair;

[0026] B carding machine ingredients: Group B: 80 kg of camel hair, 6.5 kg of elastic fiber, 1.5 kg of antistatic fiber, 2 kg of antibacterial and deodorant fiber.

[0027] Step Two: Mixing

[0028] The batching of Group A is carried out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com