Technique for producing knitting face fabric of blended yarn of down feather

A knitted fabric and production process technology, applied in the processing, weaving, knitting and other directions of textile materials, can solve problems such as irritation of the skin, inability to produce and use normally, and achieve the effect of thinning and fashionable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Viscose cotton feather knitted fabric

[0021] Raw material: the surface layer yarn is 100% viscose, 40s / 1; the middle layer down blended yarn is down 20% / viscose 60% / polyester 20%, 32s / 1; the inner bottom yarn is cotton 40% / modal 60% Blended yarn, 24s / 1.

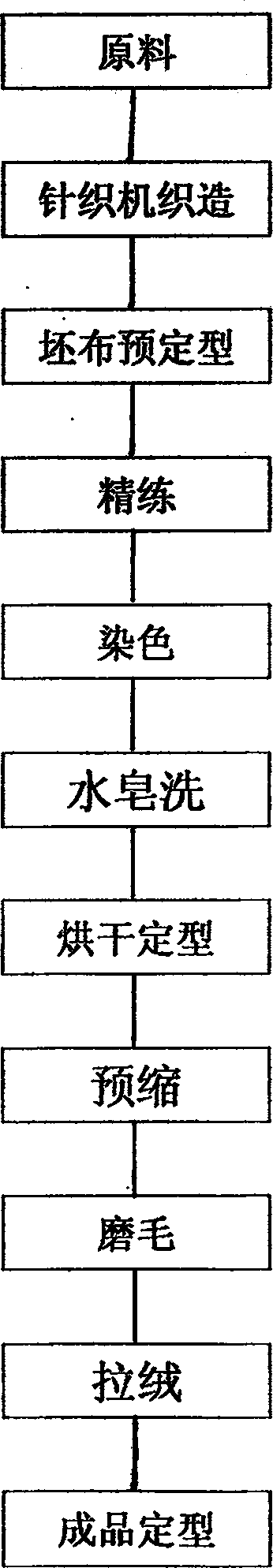

[0022] Processing method: raw material-knitting machine weaving-grey fabric pre-sizing-scouring-dyeing-soaping-drying and setting-pre-shrinking-sanding-brushing-final product setting.

[0023] Raw material process: Three feeds are used; one is the surface veil, 100% viscose, 40s / 1; the other is the inner bottom yarn, cotton 40% / modal 60% blended yarn, 24s / 1; the other is the middle layer connection Blended yarn with down, down 20% / viscose 60% / polyester 20%, 32s / 1;

[0024] Knitting machine weaving process: use multi-functional belt conveying and adding spandex double-sided large circular knitting machine, three-way feed, 40D spandex is added to the inner bottom yarn to make a grey fabric.

[0025] Grey fabric pre-sizing ...

Embodiment 2

[0035] Polyester / cotton hairy knitted fabric

[0036] Material: Top layer yarn is modal 50% / polyester 30% / wool 20% blended yarn, 38s / 1; middle layer down blended yarn is down 10% / viscose 70% / polyester 20%, 32s / 1; inner layer The bottom yarn is 100% cotton, 21s.

[0037] Processing method: raw material-knitting machine weaving-grey fabric pre-sizing-scouring-dyeing-soaping-drying and setting-pre-shrinking-sanding-brushing-final product setting.

[0038] Raw material process: Three feeds are used; one is the surface veil, modal 50% / polyester 30% / wool 20% blended yarn, 38s / 1; the other is the inner bottom yarn, 100% cotton, 21s; the other is the middle Down blended yarn for layer connection, down 10% / viscose 70% / polyester 20% 32s / 1;

[0039] Knitting machine weaving process: use multi-functional belt conveying and adding spandex double-sided circular knitting machine, three-way feeding, adding 30D spandex to the inner bottom yarn to make a grey fabric.

[0040] Grey fabric pre-sizing...

Embodiment 3

[0050] Sky cotton hairy knitted fabric

[0051] Raw material: surface veil is Tencel 50% / cotton 20% / wool 30% blended yarn, 38s / 1; middle layer down blended yarn is down 15% / viscose 65% / polyester 20%, 32s / 1; lining The bottom yarn is pure cotton, 21s.

[0052] Processing method: raw material-knitting machine weaving-grey fabric pre-sizing-scouring-dyeing-soaping-drying and setting-pre-shrinking-sanding-brushing-final product setting.

[0053] Raw material process: Three feeds are used; one is surface veil, Tencel 50% / cotton 20% / wool 30% blended yarn, 38s / 1; one is the inner bottom yarn, pure cotton 21s; the other is the middle layer Connecting down blended yarn, down 15% / viscose 65% / polyester 20%, 32s / 1;

[0054] Knitting machine weaving process: use a multi-functional belt conveying and adding spandex double-sided large circle machine, three-way feeding, use 20D spandex to add the inner bottom yarn to make a grey fabric.

[0055] Grey fabric pre-sizing process: The temperature is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com