A spinning process of mixed fibers for waterproof canvas

A technology of mixed fiber and spinning process, applied in the field of spinning, can solve the problems of limited service life, easy deformation of folding, insufficient strength, etc., and achieve the effects of long service life, soft hand feeling and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the creative features, technical means and objectives of the present invention easy to understand, the present invention is further described below in conjunction with specific embodiments.

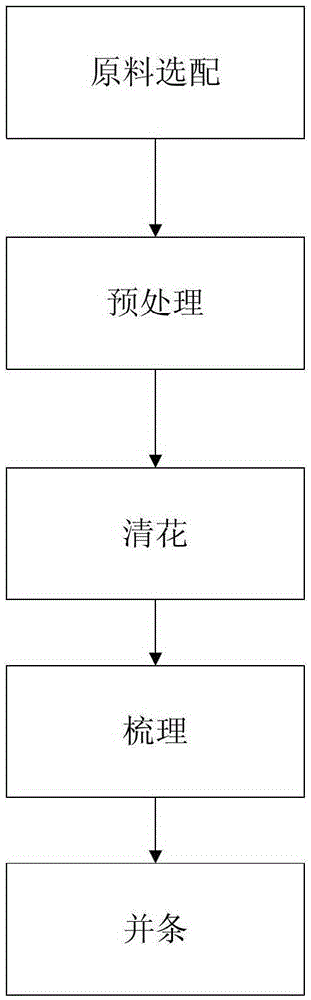

[0020] A spinning process of mixed fibers for waterproof canvas, including the following steps: raw material selection, selecting and matching several raw materials according to specific needs; pretreatment, spraying a mixture of antistatic agent and water on several raw materials in step 1) , placed for more than 24 hours, so that the mixture fully penetrates the raw materials; cleaning, the pretreated raw materials are placed on the cotton picking machine, cotton opener, cotton blending machine, cotton feeding machine, cotton mixing machine, cotton condenser, and lapping machine Opening, mixing, and rolling, so that the unevenness is within 1; carding, carding the raw materials after cleaning, straightening and straightening the fibers, so as to reduce damage to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com