Coating composition for solar cell protective covers

A solar cell and composition technology, applied in polyurea/polyurethane coatings, coatings, circuits, etc., can solve the problems of insufficient improvement in solvent resistance, weather resistance, durability, and insufficient curing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0125] (II) Transparent resin:

[0126] polycarbonate

[0127] (III) Outer coating:

[0128] Cured product of the following curable fluorine-containing coating composition

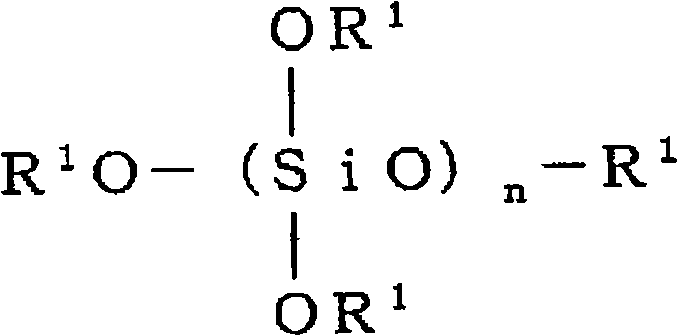

[0129] (A) Curable fluororesin:

[0130] Curable fluororesin of the above (A1) (particularly TFE / vinyl ester / monomer containing a curing site (hydroxyl or carboxyl group) copolymer)

[0131] (B) curing agent:

[0132] Isocyanate

[0133] (C) Solvent:

[0134] The third organic solvent (especially coal tar essence)

[0135] (D) Additives:

[0136] Hydrophilic agent, UV absorber, silane coupling agent

[0137] (IV) Primer coat:

[0138] none

Embodiment approach 2

[0140] (II) Transparent resin: polyethylene terephthalate

[0141] (III) Outer coating:

[0142] Cured product of the following curable fluorine-containing coating composition

[0143] (A) Curable fluororesin:

[0144] Curable fluororesin of the above (A1) (particularly CTFE / vinyl ether / monomer containing curing site (hydroxyl or carboxyl group) copolymer)

[0145] (B) curing agent:

[0146] Isocyanate

[0147] (C) Solvent:

[0148] The third organic solvent (especially mineral essential oil)

[0149] (D) Additives:

[0150] Silane coupling agent, UV absorber

[0151] (IV) Primer coat:

[0152] none

Embodiment approach 3

[0154] (II) Transparent resin:

[0155] Acrylic

[0156] (III) Outer coating:

[0157] Cured product of the following curable fluorine-containing coating composition

[0158] (A) Curable fluororesin:

[0159] Curable fluororesin of the above (A1) (particularly a mixture of a copolymer of TFE / vinyl ester / monomer containing a curing site (hydroxyl or carboxyl group) and a curable acrylic resin)

[0160] (B) curing agent:

[0161] Isocyanate

[0162] (C) Solvent:

[0163] The third organic solvent (especially coal tar essence)

[0164] (D) Additives:

[0165] UV absorber

[0166] (IV) Primer coat:

[0167] none

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com