A kind of plum blossom tube and its production process

A plum-blossom pipe and titanium dioxide technology, which is applied in the field of plum-blossom pipe and its production process, can solve the problems of limited improvement of impact resistance and inability to meet the high strength and high impact resistance of PVC pipes and fittings, and achieve simple steps, good appearance, Effects that are easy to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

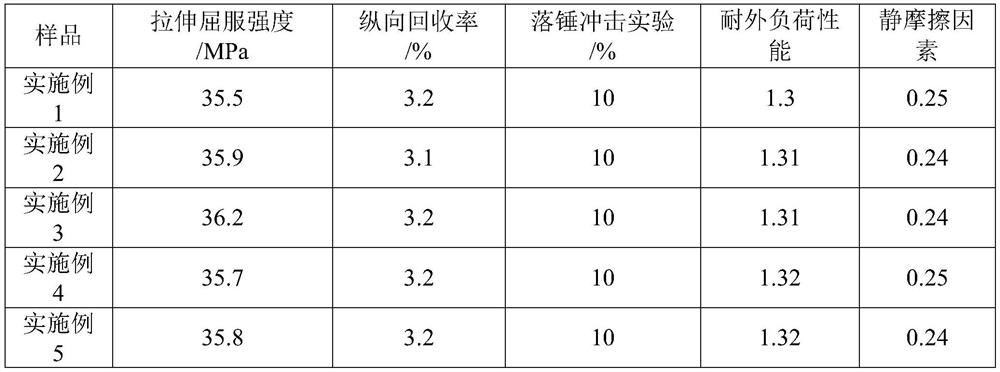

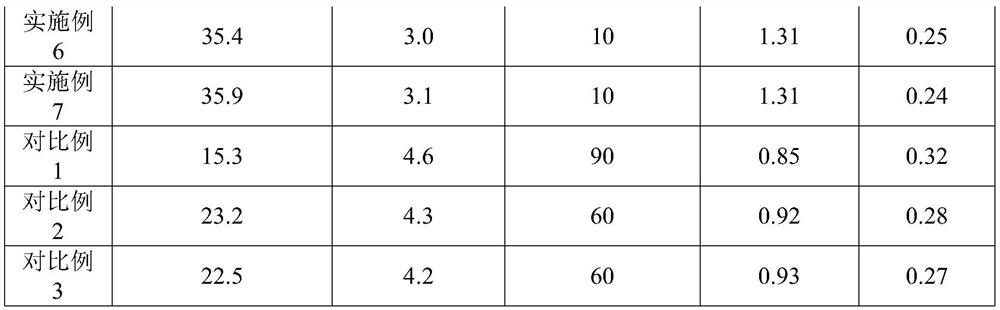

Examples

Embodiment 1

[0037] A kind of production technology of plum blossom tube comprises the steps:

[0038] Step 1: Weigh 40kg PVC resin, 2kgACR, 5kgMBS, 7kgCPE, 4kg calcium stearate, 2.5kg zinc stearate, 30kg calcium carbonate, 5kg rutile titanium dioxide, 1kg lubricant, 2kg synthetic vegetable ester, 1kg toughening agent and 0.5kg paraffin.

[0039] Step 2: uniformly mix the weighed calcium stearate and zinc stearate to obtain a composite stabilizer; uniformly mix the weighed calcium carbonate and rutile-type titanium dioxide to obtain a composite filler;

[0040] Step 3: Mix the weighed PVC resin, ACR, MBS, CPE, lubricant, synthetic vegetable ester, toughening agent and paraffin with the composite stabilizer and composite filler in step 2 to obtain a mixture;

[0041] Step 4: Transfer the mixture in Step 3 to an extruder for extrusion and granulation. The obtained granules are plasticized and melted at 150°C, extruded in a mold, cooled and sized, drawn, and coiled to obtain a plum blossom t...

Embodiment 2

[0043] A kind of production technology of plum blossom tube comprises the steps:

[0044] Step 1: Weigh 43kg PVC resin, 4kgACR, 6kgMBS, 6kgCPE, 3kg calcium stearate, 2kg zinc stearate, 28kg calcium carbonate, 2kg rutile titanium dioxide, 1kg lubricant, 3kg synthetic vegetable ester, 1kg toughening agent and 1kg of paraffin.

[0045] Step 2: uniformly mix the weighed calcium stearate and zinc stearate to obtain a composite stabilizer; uniformly mix the weighed calcium carbonate and rutile-type titanium dioxide to obtain a composite filler;

[0046] Step 3: Mix the weighed PVC resin, ACR, MBS, CPE, lubricant, synthetic vegetable ester, toughening agent and paraffin with the composite stabilizer and composite filler in step 2 to obtain a mixture;

[0047] Step 4: Transfer the mixture in Step 3 to an extruder for extruding and granulating. The obtained granules are plasticized and melted at 160°C, extruded in a mold, cooled and sized, drawn, and coiled to obtain a plum blossom tu...

Embodiment 3

[0049] A kind of production technology of plum blossom tube comprises the steps:

[0050] Step 1: Weigh 57kg PVC resin, 3kgACR, 4kgMBS, 3kgCPE, 0.7kg calcium stearate, 1kg zinc stearate, 25kg calcium carbonate, 3kg rutile titanium dioxide, 0.6kg lubricant, 1.5kg synthetic vegetable ester, 0.6 kg toughening agent and 0.6kg paraffin.

[0051] Step 2: uniformly mix the weighed calcium stearate and zinc stearate to obtain a composite stabilizer; uniformly mix the weighed calcium carbonate and rutile-type titanium dioxide to obtain a composite filler;

[0052] Step 3: Mix the weighed PVC resin, ACR, MBS, CPE, lubricant, synthetic vegetable ester, toughening agent and paraffin with the composite stabilizer and composite filler in step 2 to obtain a mixture;

[0053] Step 4: Transfer the mixture in Step 3 to an extruder for extruding and granulating. The obtained granules are plasticized and melted at 170° C., extruded in a mold, cooled and sized, drawn, and coiled to obtain a plum ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com