Portable photo-thermal seawater desalination hollow fiber membrane, preparation method, device and application

A fiber membrane and portable technology, applied in the field of portable photothermal seawater desalination hollow fiber membrane and its preparation, can solve the problems of unavoidable heat loss, limited wide use, low photothermal efficiency, etc., and achieve uniform black appearance, excellent mechanical strength, The effect of high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

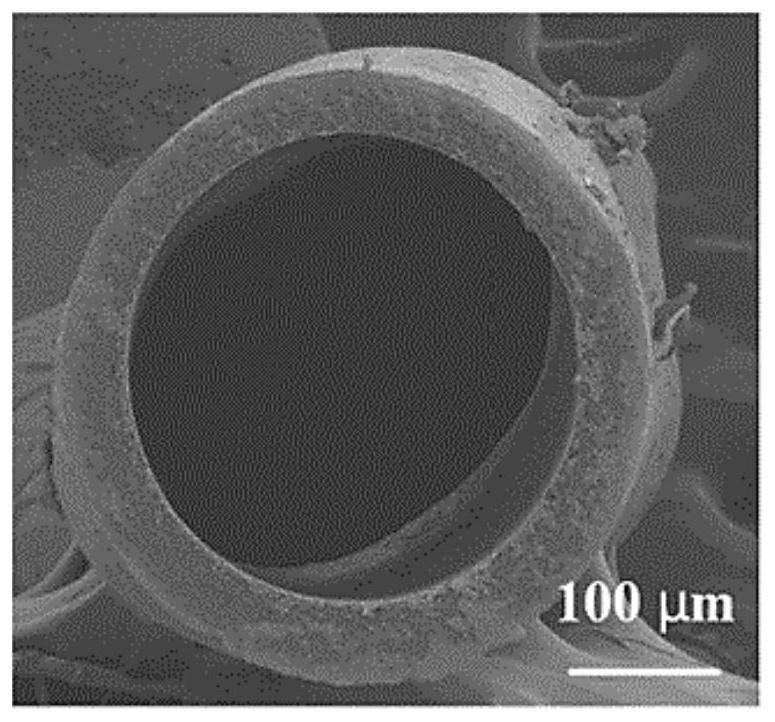

[0064] Firstly, Example 1 provides a preparation method of hollow fiber membranes for photothermal seawater desalination: using superfiber membranes with an average pore size of 0.9 μm, a porosity of 60%, a membrane thickness of 200 μm, and inner / outer diameters of 0.5 mm / 1.0 mm respectively. The hydrophilic polysulfone hollow fiber gradient membrane is used as the polymer base membrane, and the 0.5wt% carbon nanotube dispersion is fixed on the outer surface of the hollow fiber membrane through surface adsorption by vacuum filtration technology for 1 hour, so that the outer surface has photothermal function The black appearance hollow fiber membrane of the first layer can be obtained after washing and drying the hollow fiber membrane for photothermal seawater desalination.

[0065] The polymer hollow fiber membrane modified by carbon nanotubes has excellent self-siphon performance, and the appearance is uniform black. Secondly, this embodiment 1 also provides a portable photot...

Embodiment 2

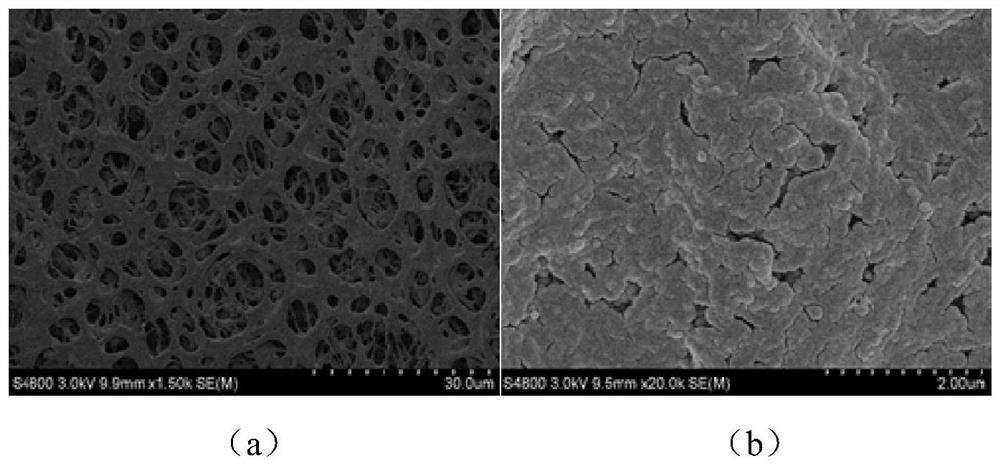

[0067] First, Example 2 provides a method for preparing a hollow fiber membrane for photothermal seawater desalination: Step 1: adopt an average pore diameter of 2 μm, a porosity of 80%, a membrane thickness of 50 μm, and an inner / outer diameter of 0.1 mm / 0.25 mm The hydrophobic polyethylene hollow fiber membrane is a polymer base membrane, and dopamine and polyethyleneimine are dispersed and dissolved in a buffer solution with a pH of 8.5 to form a uniform solution, wherein the ratio of dopamine: polyethyleneimine is 1:1; The surface coating technology was treated for 12 hours to fix the homogeneous solution on the inner surface of the hollow fiber membrane, and then cleaned and dried for later use;

[0068] Step 2: Put the polymer base membrane treated in step 1 in a 2wt% polypyrrole solution to modify the outer surface by vapor deposition for 3 hours to obtain a hollow fiber membrane with a black appearance and a photothermal functional layer on the outer surface. After clea...

Embodiment 3

[0072] Firstly, Example 3 provides a method for preparing hollow fiber membranes for photothermal seawater desalination: using ultra-thin membranes with an average pore size of 1.0 μm, a porosity of 40%, a membrane thickness of 200 μm, and inner / outer diameters of 2.0 mm / 3.5 mm, respectively. The hydrophilic polyethersulfone hollow fiber membrane is a polymer base membrane, and the superhydrophilic polyethersulfone hollow fiber membrane is placed in a 20wt% polyaniline solution for cross-linking and fixing modification of the outer surface for 6 hours, and the outer surface has a light The black appearance hollow fiber membrane of the thermal functional layer can be washed and dried to obtain the hollow fiber membrane for photothermal seawater desalination. The polyaniline-modified polymer hollow fiber membrane prepared in Example 3 has excellent self-siphon performance, and its appearance is uniform black.

[0073]Secondly, this embodiment 3 also provides a portable photother...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com