High-gloss multi-proof thermo-sensitive recording material and preparation method thereof

A recording material and high-gloss technology, which is applied in the field of multi-anti-heat-sensitive recording materials and multi-anti-heat-sensitive recording materials, to achieve high stiffness, high smoothness, and no thickness loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

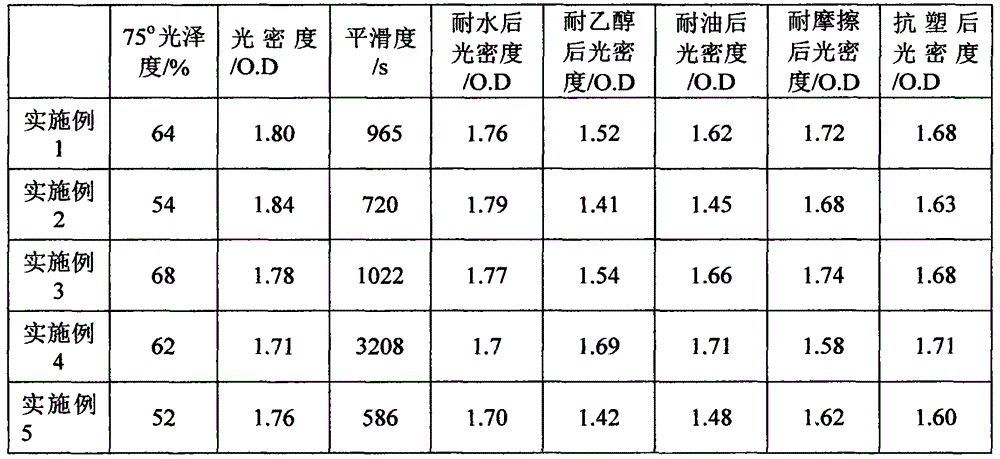

Examples

Embodiment 1

[0051] The base material is all wood pulp base paper (60% hardwood pulp, 40% softwood pulp), basis weight 65g / m 2 , 16% ash, Cobb 30s 21g / m 2 , front smoothness 82s.

[0052] The film material is a polyester film with a thickness of 35 μm for transfer.

[0053] The composition of the pre-coating is as follows: 68% of calcined kaolin, 15% of hollow balls, 14% of styrene-butadiene latex, 0.5% of sodium polyacrylate, 0.2% of carboxymethyl cellulose and 2.3% of calcium stearate. The solid content of the pre-coating is 46%, and it is coated by a doctor blade, and the coating amount is 7.2g / m 2 .

[0054] The composition of the top coating is as follows: calcined kaolin 10%, light calcium carbonate 18%, polyvinyl alcohol 10%, carboxylated styrene-butadiene latex 6%, 4-hydroxy-4'-isopropoxydi Phenylsulfone 24%, 2-anilino-3-methyl-6-dibutylaminofluoran or 2-(2-4-xylanilino)-3-methyl-6-diethylaminofluoran 10% , benzyl-2-naphthyl ether 17.8%, zinc stearate 4%, antioxidant 11000.2%...

Embodiment 2

[0059] Method is the same as embodiment 1, just change top coat coating amount and be 1.4g / m 2 , thus obtaining a thermosensitive recording material.

Embodiment 3

[0061] The method is the same as in Example 1, except that the lubricant in the top coating formula is changed to zinc stearate accounting for 6%, and paraffin wax emulsion accounting for 2%, thus obtaining a heat-sensitive recording material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com