Water-emulsion plant adhesive and its preparation method

An adhesive and water-emulsion type technology, which is applied in the field of water-emulsion type plant adhesive and its preparation, can solve the problems of large environmental pollution, energy consumption and high operation risk, and achieve the effects of eliminating pollution, easy transfer, and energy consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

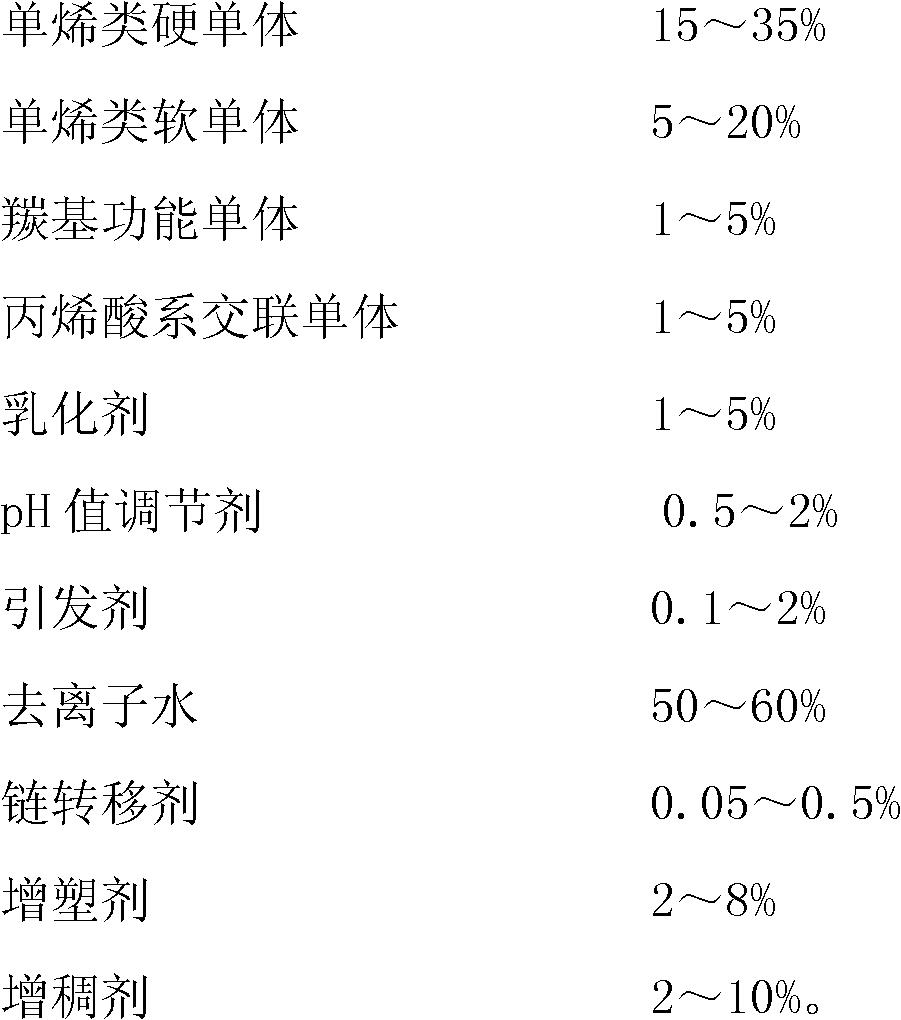

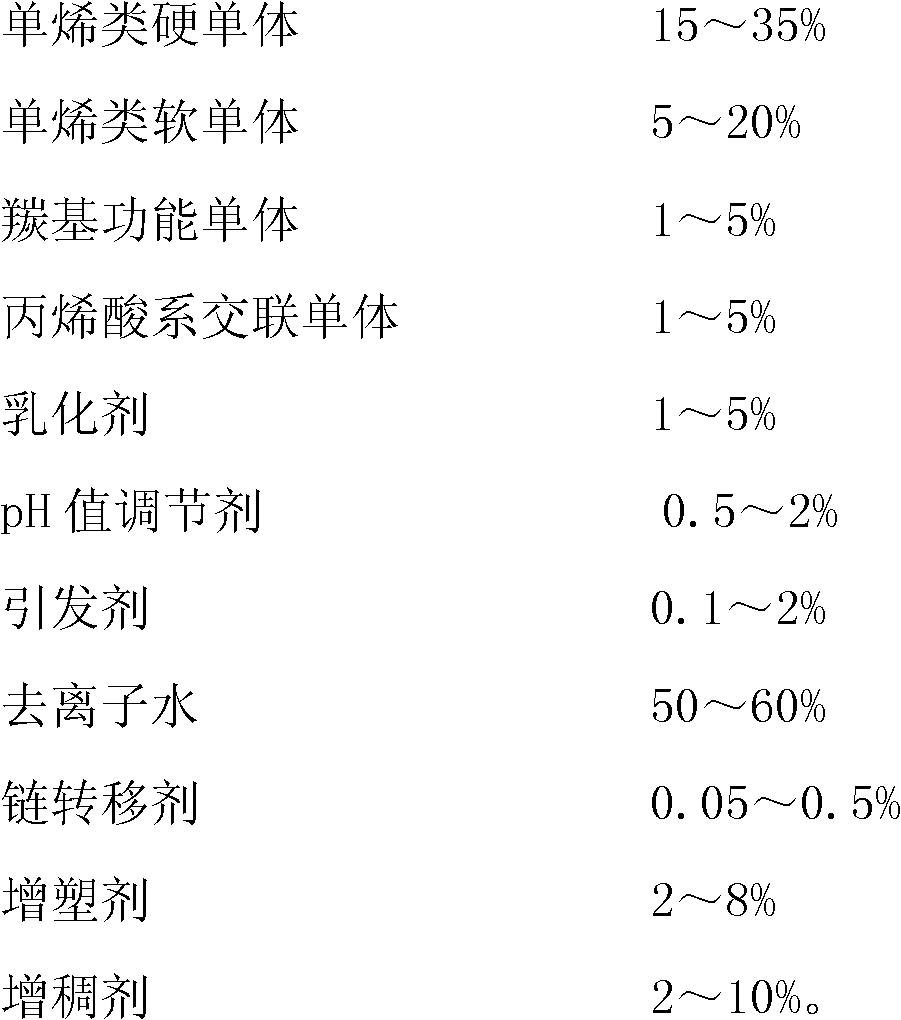

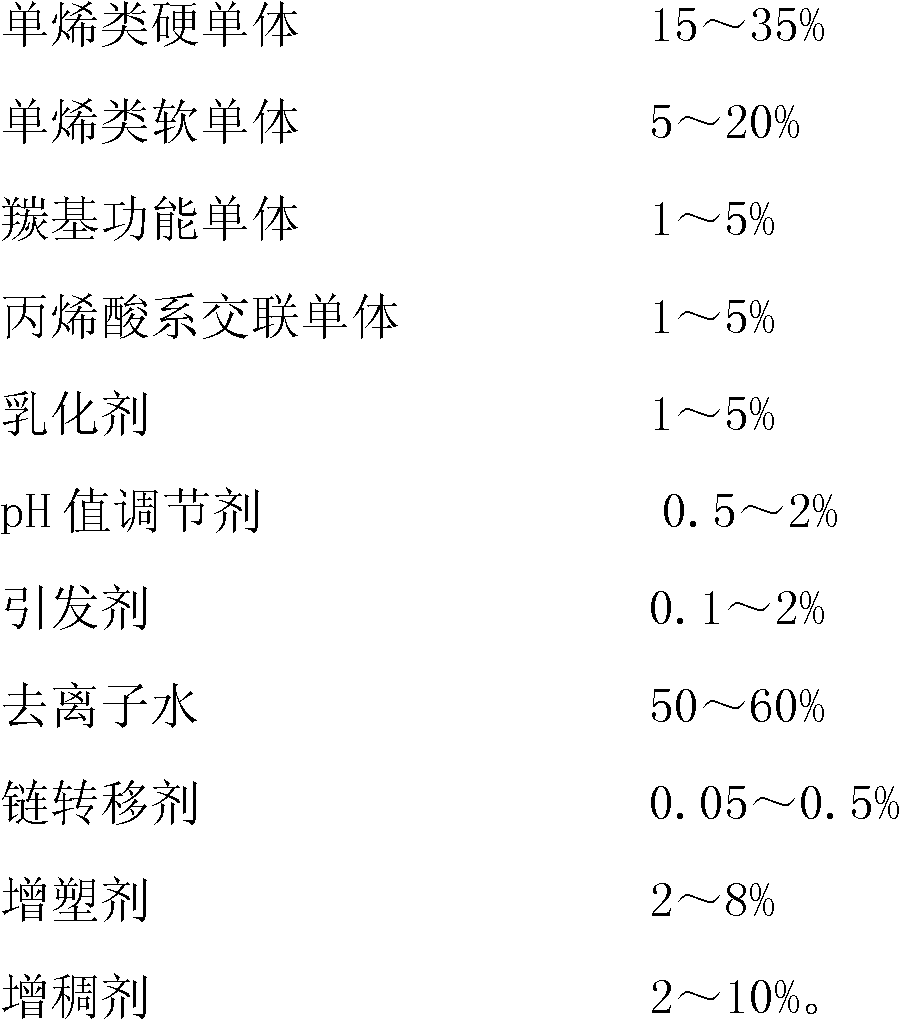

[0046] The preparation method of the above-mentioned water-emulsion type plant adhesive specifically includes:

[0047] Get each raw material according to the formula of water-emulsion type plant adhesive;

[0048] Pre-emulsification:

[0049] The deionized water which accounts for 35% of the total weight of deionized water and the emulsifier which accounts for 2 / 3 of the total weight of the emulsifier are stirred at a stirring rate of 50 Hz for 10 to 15 minutes to form a stirred liquid, which will account for the total amount of monoene hard monomers. 2 / 3 of the monoolefinic hard monomer, all monoolefinic soft monomers, carbonyl functional monomers, acrylic crosslinking monomers, and chain transfer agents are added to the stirring liquid, and then added to account for 1% of the total weight of the pH regulator. / 2 of the pH regulator, the initiator accounting for 1 / 3 of the total weight of the initiator, stirred for 30 to 40 minutes to obtain a pre-emulsion;

[0050] Polyme...

Embodiment 1

[0057] This embodiment provides a water-emulsion type plant adhesive, which is a single-group adhesive using water as a solvent. The adhesive is composed of the raw materials in the following table, specifically:

[0058] components

Weight (Kg)

Styrene (St) (monoolefin hard monomer)

10

n-Butyl Methacrylate (MBA) (Monoolefin Hard Monomer)

15

Ethyl Acrylate (EA) (Monoolefinic Soft Monomer)

15

Acrylic acid (AA) (carbonyl functional monomer)

1.5

Hydroxypropyl Methacrylate (HPA)

2.5

Nonylphenol polyoxyethylene (10) ether ester disodium sulfosuccinate (MS-1) (emulsifier)

1.0

Sodium dodecylbenzenesulfonate (SDBS) (emulsifier)

0.6

Sodium bicarbonate (pH adjuster)

1.0

Ammonium persulfate (APS) (initiator)

0.6

Deionized water

47.7

Dodecyl Mercaptan (Chain Transfer Agent)

0.1

2.0

Fumed silica (t...

Embodiment 2

[0067] This embodiment provides a water-emulsion type plant adhesive, which is a single-group adhesive using water as a solvent. The adhesive is composed of the raw materials in the following table, specifically:

[0068] components

Weight (Kg)

Methyl methacrylate (MMA) (monoolefin hard monomer)

14

Methyl Acrylate (MBA) (Monoolefin Hard Monomer)

17

Butyl Acrylate (Monoolefinic Soft Monomer)

8

Methacrylic acid (carbonyl functional monomer)

3.0

Hydroxyethyl Acrylate (Acrylic Crosslinking Monomer)

1.5

Disodium Decyl Ether Sulfosuccinate (A-102) (Emulsifier)

1.2

Alkylphenol polyoxyethylene ether (10) (OP-10) (emulsifier)

0.4

[0069] Sodium bicarbonate (pH adjuster)

1.5

Ammonium persulfate (APS) (initiator)

0.4-

Deionized water

44.9

Dodecyl Mercaptan (Chain Transfer Agent)

0.1

Sebacate (plasticizer)

3.0

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com