Transdermal gel patch for promoting drugs with low skin absorption ability and preparation method of transdermal gel patch

A technology of transdermal gel patch and absorption capacity, applied in the field of medicine, can solve the problems of many components, complicated preparation method, etc., and achieve the effects of improving the penetration amount, simple preparation method and few auxiliary materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] Embodiment 1, the preparation of a kind of tanshinone IIA nano drug crystal

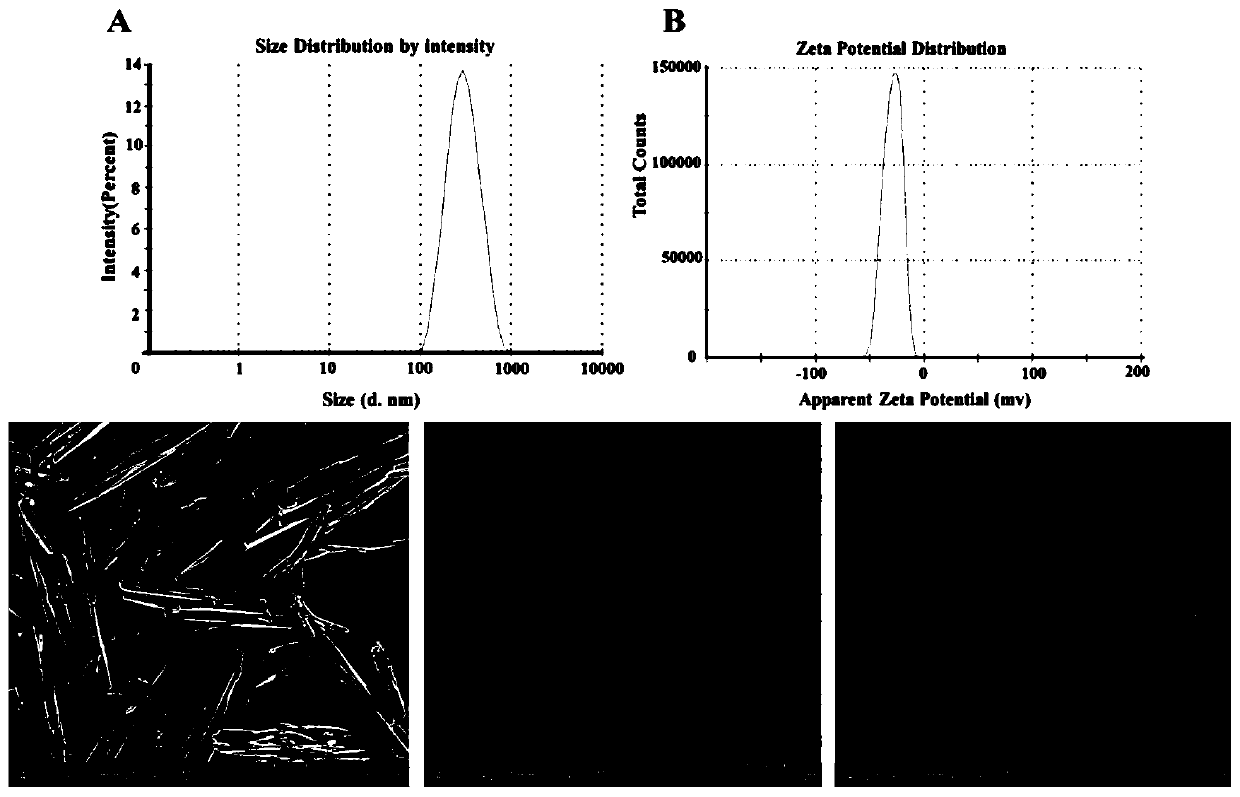

[0075] Weigh 0.05g of sodium lauryl sulfate and 0.08g of hydroxypropyl methylcellulose E5, add them into 30mL of distilled water to make them fully dissolve and swell, add 0.3g of tanshinone ⅡA raw material under magnetic stirring, and stir for 20 minutes to obtain coarse suspension. This coarse suspension is then transferred to a nanomill for grinding. Grinding conditions are: the particle size of yttrium-stabilized zirconia grinding beads is 0.6-0.8mm, the rotation speed of the stirring shaft is 2000rpm, and the particle size and potential are sampled after 45 minutes. figure 1 A and 1B.

[0076] Take a fresh sample of the prepared tanshinone IIA nanosuspension, add mannitol as a lyoprotectant at a concentration of 1% m / v, then pre-freeze at -70°C for 24 hours, and then transfer to a freeze dryer for lyophilization , to obtain freeze-dried nanocrystals. Among them, the scanning electron ...

Embodiment 2

[0077] Example 2, Preparation of Tanshinone IIA Mesoporous Silica Dispersion

[0078] Weigh 0.5g of Tanshinone IIA, dissolve it in 35ml of chloroform, make it fully dissolved, add 1g of Syloid244FP (pore size 20nm) mesoporous silica under magnetic stirring, ultrasonically disperse for 20-40min, then magnetically stir for 24 hours, take the precipitate Place in a vacuum drying oven and dry to constant weight to obtain a mesoporous silica dispersion whose surface morphology is as follows: figure 1 As shown in E, it can be seen that the tanshinone IIA silica dispersion maintains its amorphous state.

Embodiment 3

[0079] Embodiment 3, the preparation of tanshinone IIA gel patch

[0080] Prepared by the following steps:

[0081] (1) Disperse 56% sodium polyacrylate X30, 0.1% aluminum glycolate, 0.05% aluminum hydroxide, and 0.1% methylparaben in 30% glycerin under stirring conditions to form phase A.

[0082] (2) Disperse 0.15% tartaric acid, 2% polyvinyl alcohol, and 902% polyvinylpyrrolidone K in water under agitation to form phase B.

[0083] (3) Disperse the tanshinone IIA powder and the nanocrystal or mesoporous silica dispersion with the same drug loading in the phase A under the condition of stirring to form the phase C.

[0084] (4) Add phase B to phase C, mechanically stir until it can be coated, and then use a glass rod to evenly coat the non-woven fabric (7×10cm) with a thickness of 1mm. After coating, leave it at room temperature for 24 hours Put the anti-adhesive film on the back cover, and you have it.

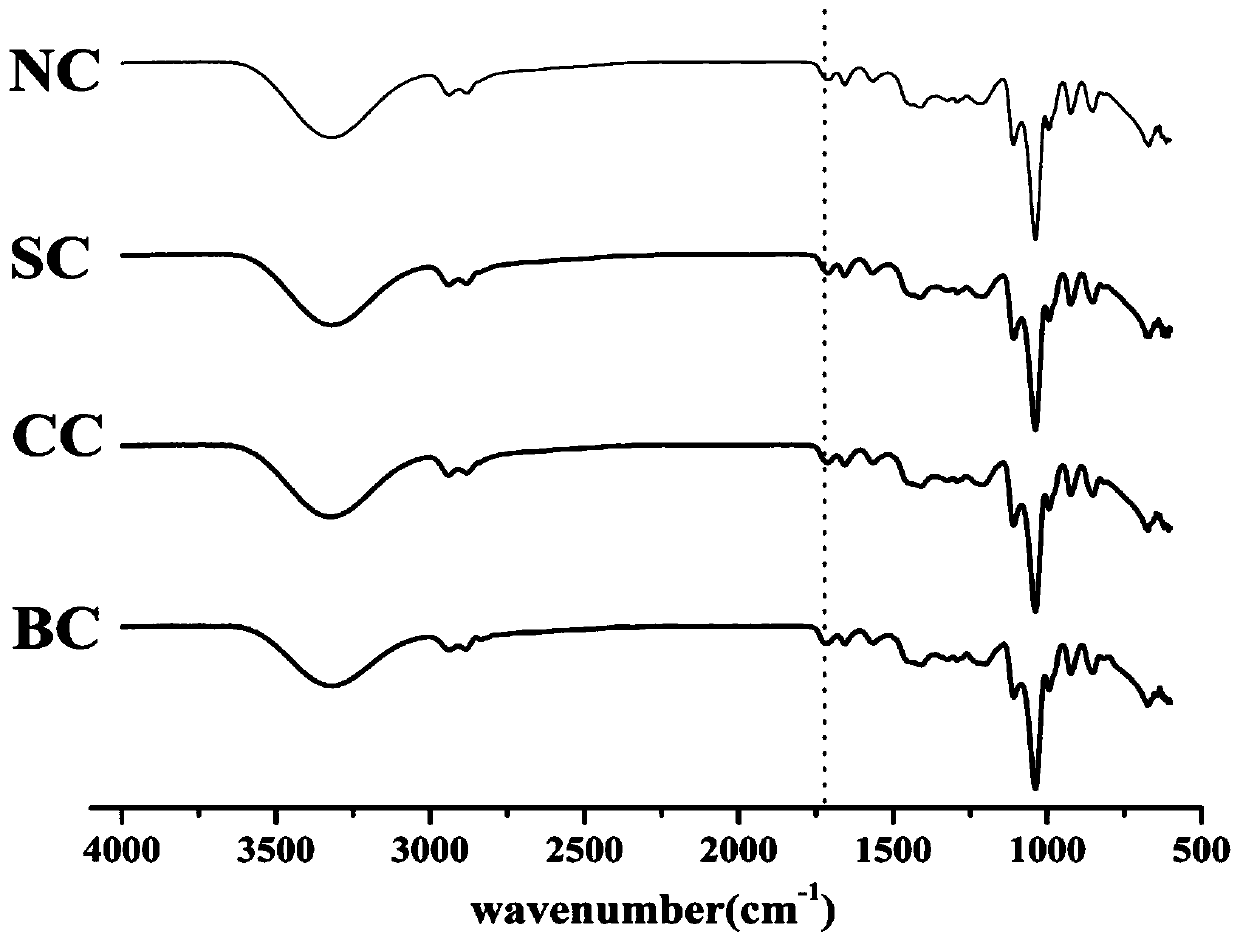

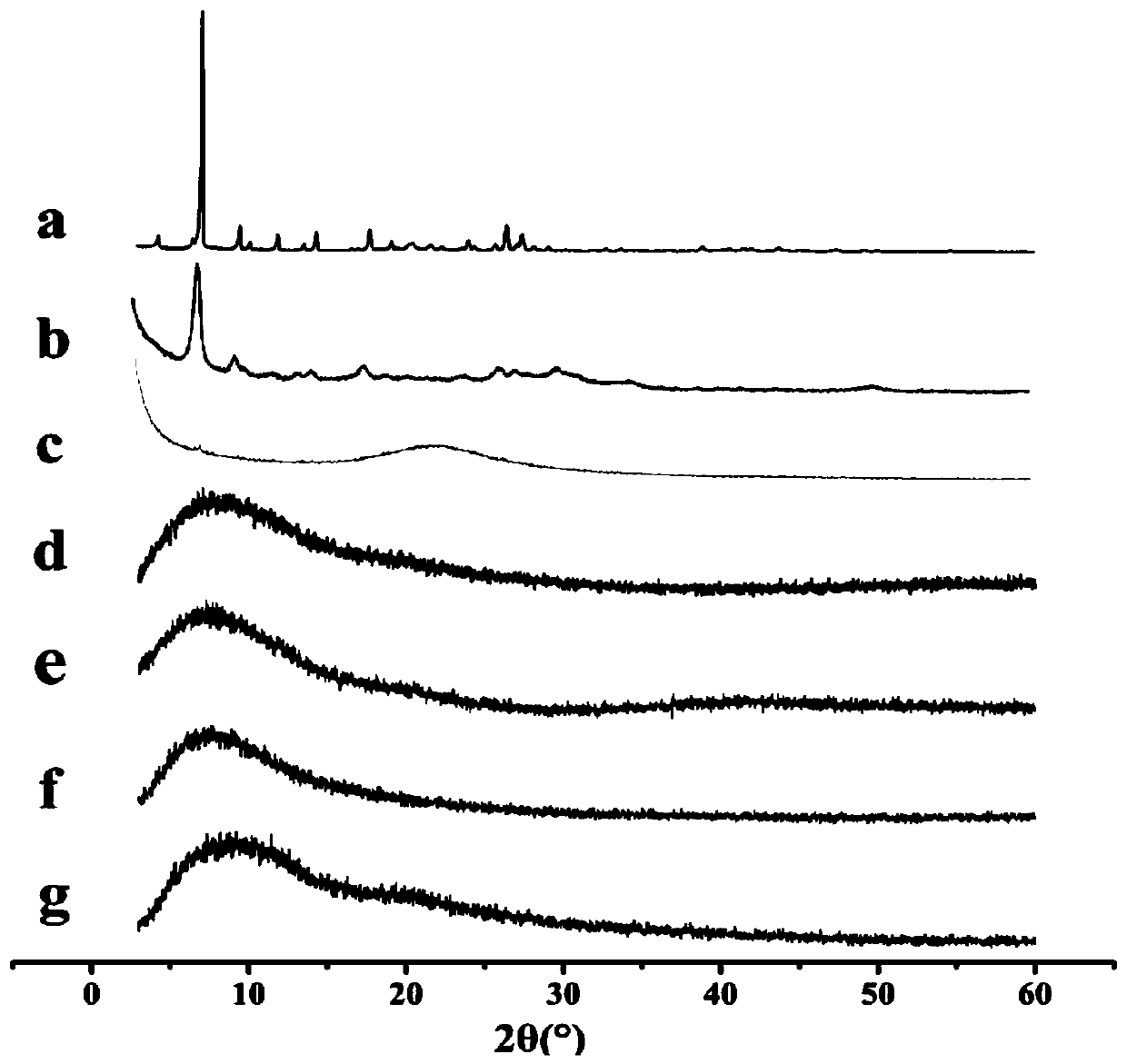

[0085] In the gel patch with tanshinone Ⅱ A as the model drug, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com