Composite substrate for fabricating flexible display, fabrication method of composite substrate and fabrication method of active matrix/organic light emitting diode (AMOLED)

A composite substrate, flexible display technology, used in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve the problem that flexible substrates and adhesives are not resistant to high temperature, no flexible display substrates, and damage to flexible substrates and carriers. Substrate adhesion and other issues, to achieve the effect of improving convenience, bonding stability, and reducing substrate warpage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

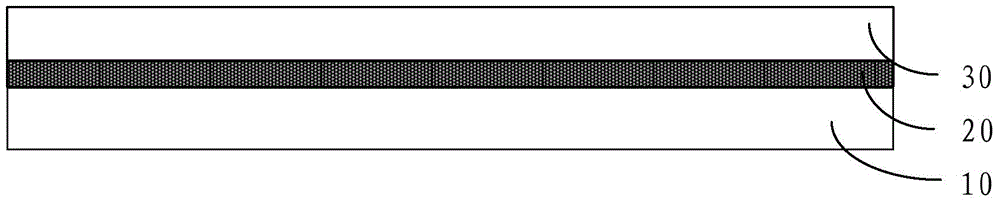

[0046] Further, the present invention also proposes the above-mentioned preparation method of the composite substrate for flexible display manufacturing, including the following steps:

[0047] S10a, obtaining the hard substrate 10, and performing surface activation treatment on the hard substrate 10;

[0048] S20a, coating the resin solution of the high temperature resistant thin film layer 20 on the activated surface of the hard substrate 10 to form the high temperature resistant thin film layer 20;

[0049] S30a, drying the hard substrate 10 coated with the high temperature-resistant thin film layer 20 after standing in a vacuum;

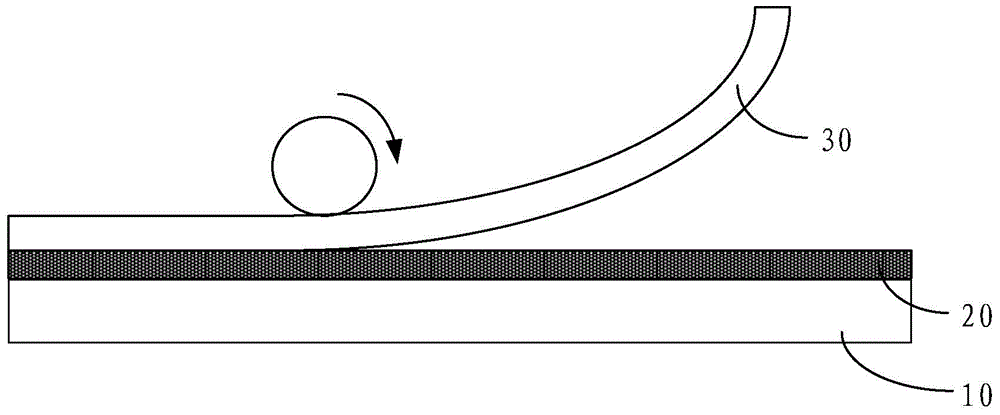

[0050] S40a, attaching the resin casting film of the high temperature resistant flexible substrate layer 30 to the surface of the dried high temperature film layer 20 to form the high temperature resistant flexible substrate layer 30;

[0051] S50a, the hard substrate 10 with the high temperature resistant flexible substrate layer 30 is subjecte...

Embodiment 1

[0084] In this embodiment 1, a phthalic anhydride-type PI resin material is used to realize the preparation of the composite layer, and a high-brightness glass plate is selected as the hard substrate.

[0085] S10, ultrasonically cleaning the glass plate, and then performing plasma treatment on the surface of the glass plate with nitrogen after cleaning;

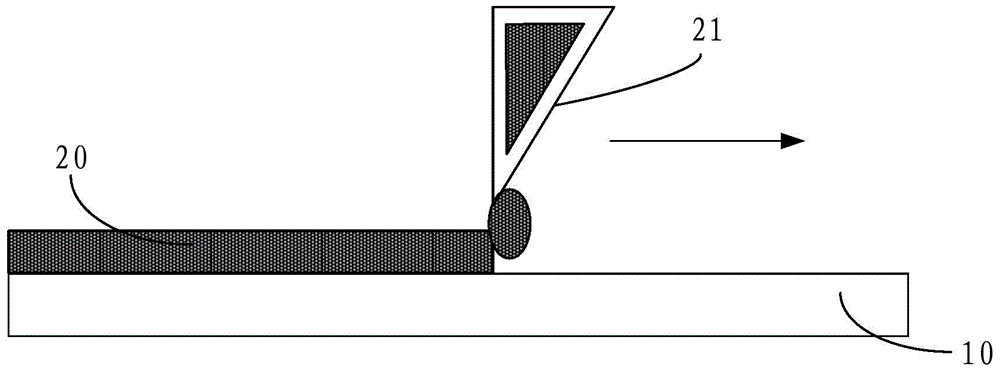

[0086] S20, use NMP (N-methylpyrrolidone) as a solvent to form a viscous solution with PI resin, and pour the solution into the inner cavity of the squeegee; fix the glass plate in a class 100 clean room, and keep the squeegee with the squeegee With a distance of 0mm-2mm on the surface of the glass plate, scrape slowly and uniformly to form a high-temperature resistant film layer; after the scrape coating is completed, use a rotary machine to rotate the glass plate to the high-temperature resistant film layer to form a flat and uniform film with a thickness of 2μm-5μm;

[0087] S30, after the coating is completed, quickly tr...

Embodiment 2

[0095] In this embodiment 2, a biphenyl type PI resin material is used to realize the preparation of the composite layer, and a silicon wafer is selected as the hard substrate.

[0096] S10, after ultrasonically cleaning the silicon wafer, performing argon plasma treatment on the surface of the silicon wafer with a plasma surface treatment machine;

[0097] S20, use DMAc (dimethylacetamide) as a solvent to form a viscous solution with PI resin, and pour the solution into the inner cavity of the scraping knife; fix the silicon wafer in a class 100 clean room, keep the scraping knife and With a distance of 0mm-2mm on the surface of the silicon wafer, scrape slowly and uniformly to form a high-temperature resistant film layer; after the scrape coating is completed, use a rotary machine to rotate the silicon wafer to the high-temperature resistant film layer to form a flat and uniform film with a thickness of 2μm-5μm;

[0098] S30, after the coating is completed, quickly transfer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com