Method for preparing high-adhesion micro-nano array structure film through wet etching and reverse transfer printing

A technology with an array structure and high adhesion, applied in the field of nanomaterials, can solve the problems of expensive optical exposure equipment, harsh processing environment, complex process flow, etc., to achieve simple and fast operation, simple solution ratio, and strong adjustability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

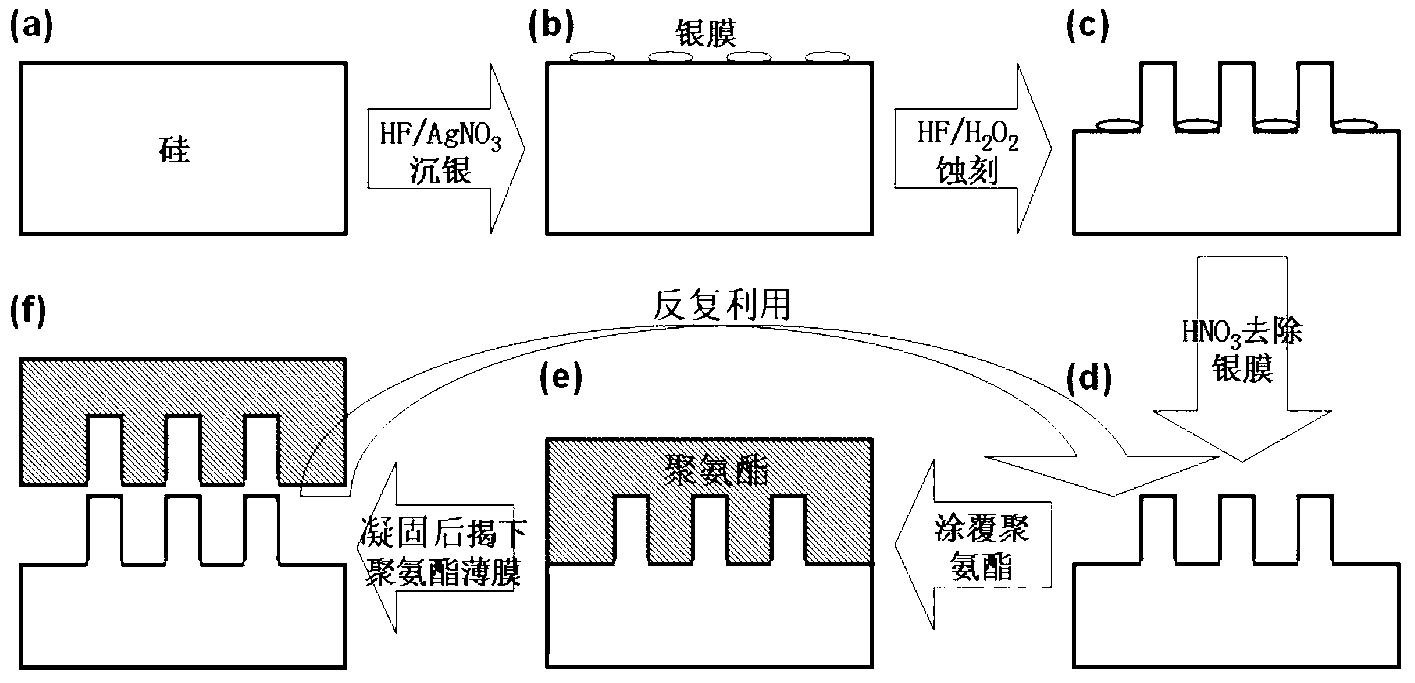

[0025] Taking the preparation of highly adhesive nanowire array structure film as an example

[0026] (1) Silicon wafer cleaning: use alcohol, acetone, hydrogen peroxide (mass fraction 30%): ammonia water (mass fraction 25%-28%): deionized water = 1:1:5 (volume ratio) to ultrasonically clean the single crystal Silicon wafers for 20 minutes, then soaked in hydrogen peroxide (30% mass fraction): concentrated sulfuric acid (98% mass fraction): deionized water = 3:1 (volume ratio) for 8 hours;

[0027] (2) Deposit porous silver film on silicon wafer: 0.5mmol (0.085g) silver nitrate (AgNO 3 ) and 0.46mol (20ml) hydrofluoric acid (HF, 40% mass fraction) diluted to 100ml, after stirring evenly, put the silicon wafer cleaned in step (1) into it, and let it stand at room temperature 25°C to deposit silver film for 2 minutes to obtain a silicon wafer with a porous silver film grown on the surface;

[0028] (3) Silicon nanowire array structure of required length "growth" on the silicon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com