Pipeline robot for cleaning gun barrels

A pipeline robot and cleaning technology, applied in the direction of weapon cleaning device, weapon accessories, offensive equipment, etc., can solve the problem that the structure of the variable-diameter pipeline cannot be well satisfied, and achieve the effect of simple structure, moderate adhesion and continuous movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

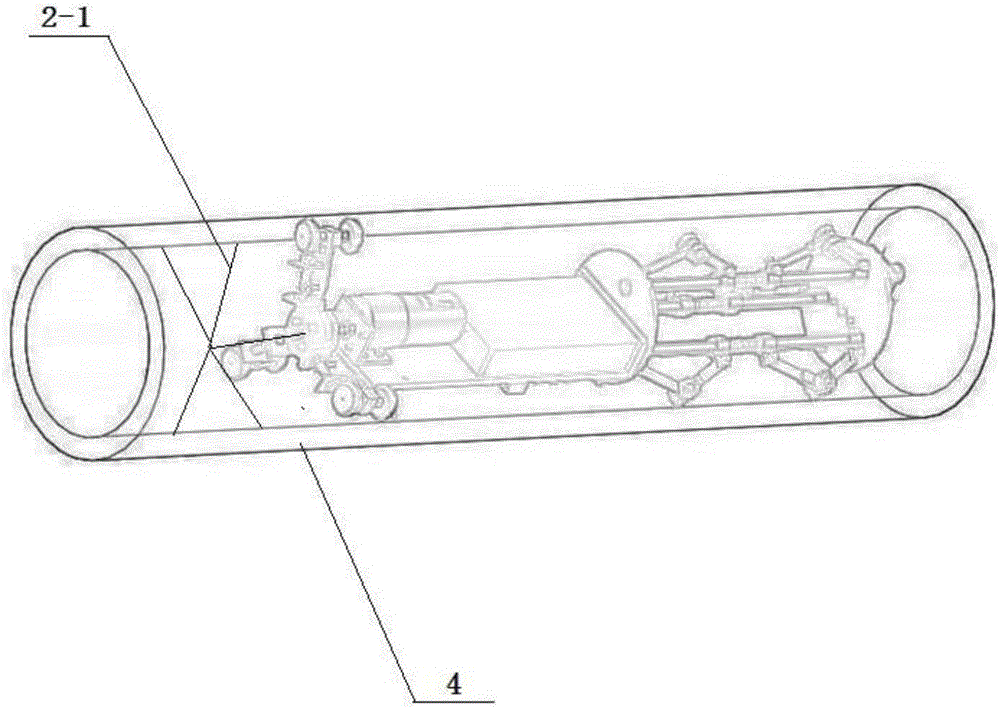

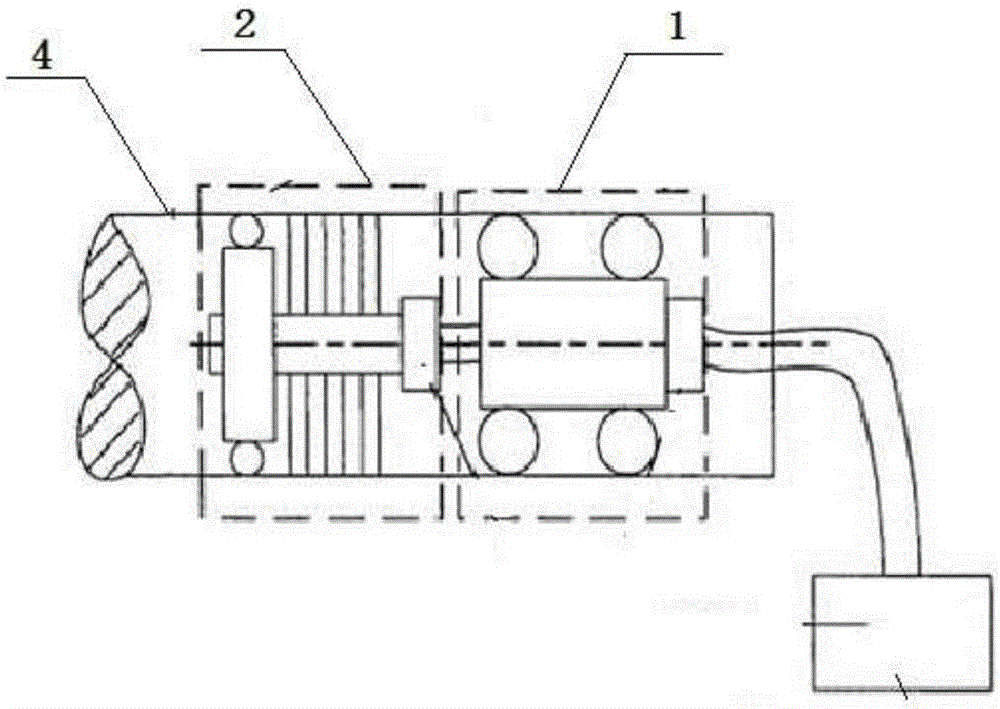

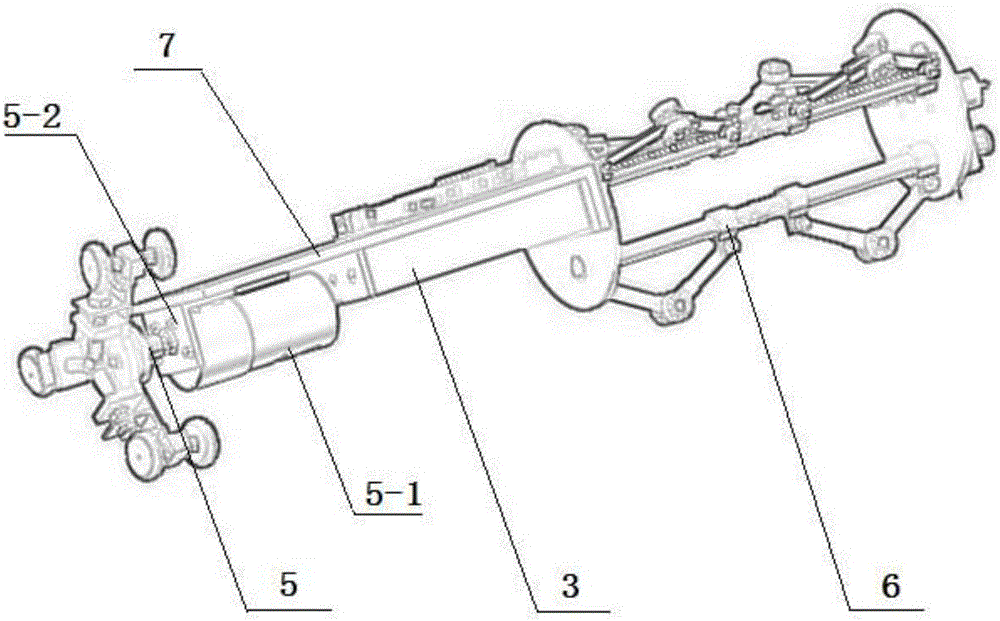

[0020] refer to Figure 1-6 , a pipeline robot for gun barrel cleaning, consisting of a spiral drive structure 1, a cleaning module 2, a control module 3 and an auxiliary camera module, the spiral drive structure consists of a support plate 7, a drive motor 5-1, a spiral Type drive execution head 5, motion holder 6, the drive motor is installed on the support plate through the motor fixing seat 5-2, the screw type drive execution head is fixed on the output shaft of the drive motor, and Rotating under the action of the drive motor, the helical drive executive head is composed of a third flange disc 5-3, an L-shaped drive wheel bracket 5-6, a wheel set, and a compression spring 5-4. The wheel set can be rotatably fixed on the L-shaped driving wheel bracket, and the three sets of L-shaped driving wheel brackets can be slidably installed on the third-divided flange disc ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com