CPE and NR co-used sheath rubber for rubber sheathed flexible cables

A sheathed rubber and flexible cable technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of large difference between day and night, low steam pressure, insufficient steam pressure stability, etc., to improve extrusion process performance and enhance elasticity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

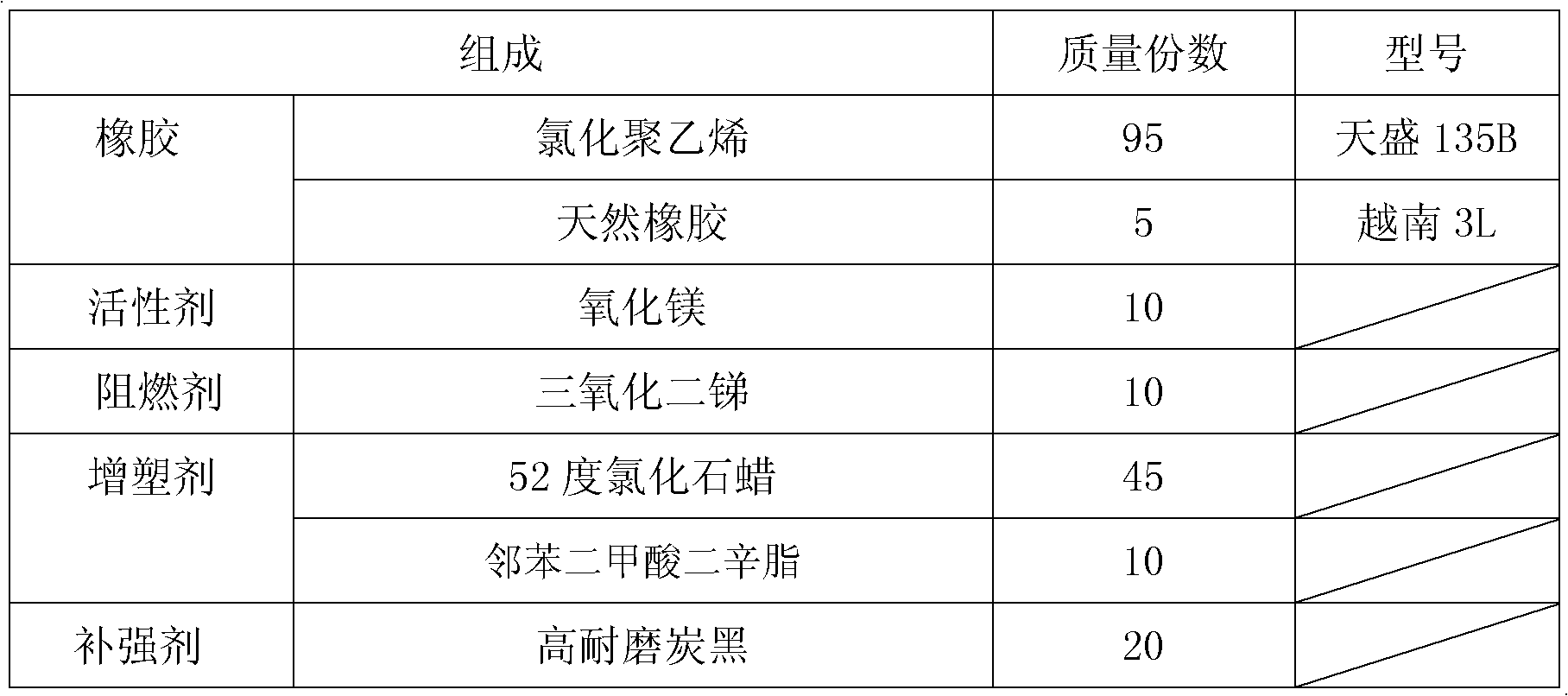

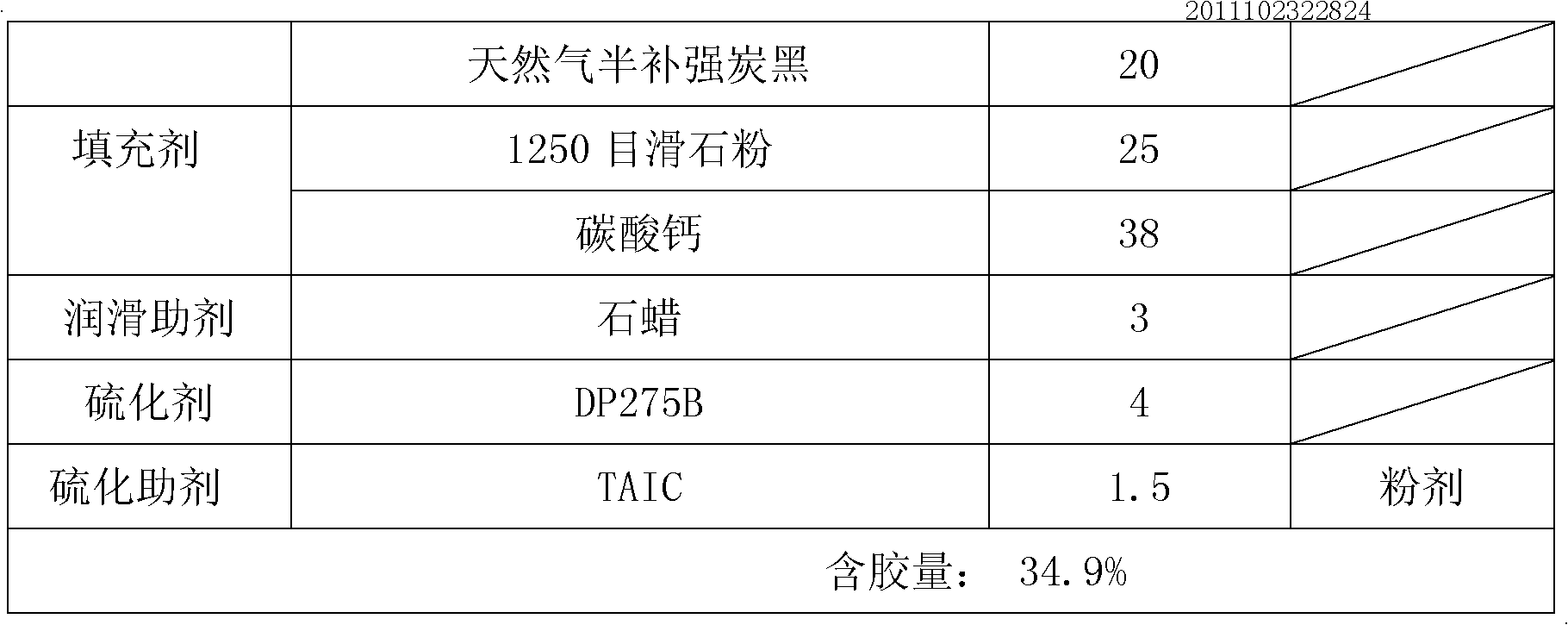

[0042] The composition, ratio and model of the rubber sheath flexible cable with DP275B as the vulcanizing agent in combination with CPE and NR are shown in Table 1:

[0043] Table I

[0044]

[0045]

[0046] In this example:

[0047] Properties of mixed film:

[0048] Mooney viscosity M(1+4) at 100°C is: 82.0Mv

[0049] The maximum torque MH at 150℃*15min on the rheometer is: 2.80N.m

[0050] The process scorch time t10 at 150℃*15min on the rheometer is: 0.97min

[0051] The process positive vulcanization time t90 at 150℃*15min on the rheometer is: 7.50min

[0052] Tensile strength: 13.2N / mm 2

[0053] Elongation: 450%

[0054] Specific gravity: 1.63g / cm 3

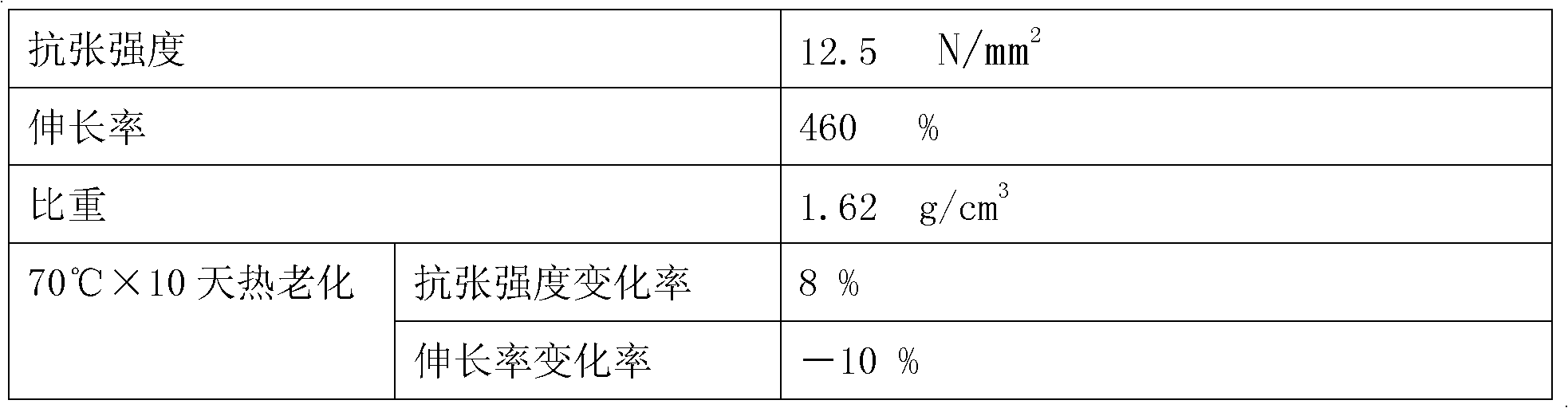

[0055] After weighing according to Table 1, carry out mastication, kneading, tableting, extrusion molding, steam pressure (0.60-0.80MPa) vulcanization to obtain the finished product, and its properties are shown in Table 2:

[0056] Table II

[0057]

Embodiment 2

[0059] The combination of CPE and NR sheath rubber for rubber sheath flexible cables using DP275B as the vulcanizing agent in this embodiment, the composition, proportions and models are shown in Table 3:

[0060] Table three

[0061]

[0062]

[0063] In this example:

[0064] Properties of mixed film:

[0065] Mooney viscosity M(1+4) at 100°C is: 80.0Mv

[0066] The maximum torque MH at 150℃*15min on the rheometer is: 3.0N.m

[0067] The process scorch time t10 at 150℃*15min on the rheometer is: 0.90min

[0068] The process positive vulcanization time t90 at 150℃*15min on the rheometer is: 6.80min

[0069] Tensile strength: 13.3N / mm 2

[0070] Elongation: 420%

[0071] Specific gravity: 1.64g / cm 3

[0072] After weighing according to Table 3, carry out mastication, kneading, sheeting, extrusion molding, steam pressure (0.60-0.80MPa) vulcanization to obtain the finished product, and its properties are shown in Table 4:

[0073] Table four

[0074]

[0075] ...

Embodiment 3

[0077] The combination of CPE and NR sheath rubber for the rubber sheath flexible cable using DP275B as the vulcanizing agent in this embodiment, the proportion and the model are shown in Table 5:

[0078] Table five

[0079]

[0080] In this example:

[0081] Properties of mixed film:

[0082] Mooney viscosity M(1+4) at 100°C is: 75Mv

[0083] The maximum torque MH at 150℃*15min on the rheometer is: 2.6N.m

[0084] The process scorch time t10 at 150℃*15min on the rheometer is: 0.90min

[0085] The process positive vulcanization time t90 at 150℃*15min on the rheometer is: 7.2min

[0086] Tensile strength: 12.2N / mm 2

[0087] Elongation: 410%

[0088] Specific gravity: 1.66g / cm 3

[0089] After weighing according to Table 5, carry out mastication, kneading, tableting, extrusion molding, steam pressure (0.60-0.80MPa) vulcanization to obtain the finished product, and its properties are shown in Table 6:

[0090] Table six

[0091]

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com