Preparation raw material for rubber soft core of rubber pipe

A technology of rubber and soft cores, applied in the direction of hoses, pipes, pipes/pipe joints/fittings, etc., can solve problems such as poor dimensional stability, low production efficiency, and continuous production of hard core method production processes, and achieve dimensional stability , Improve service life, excellent weather resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

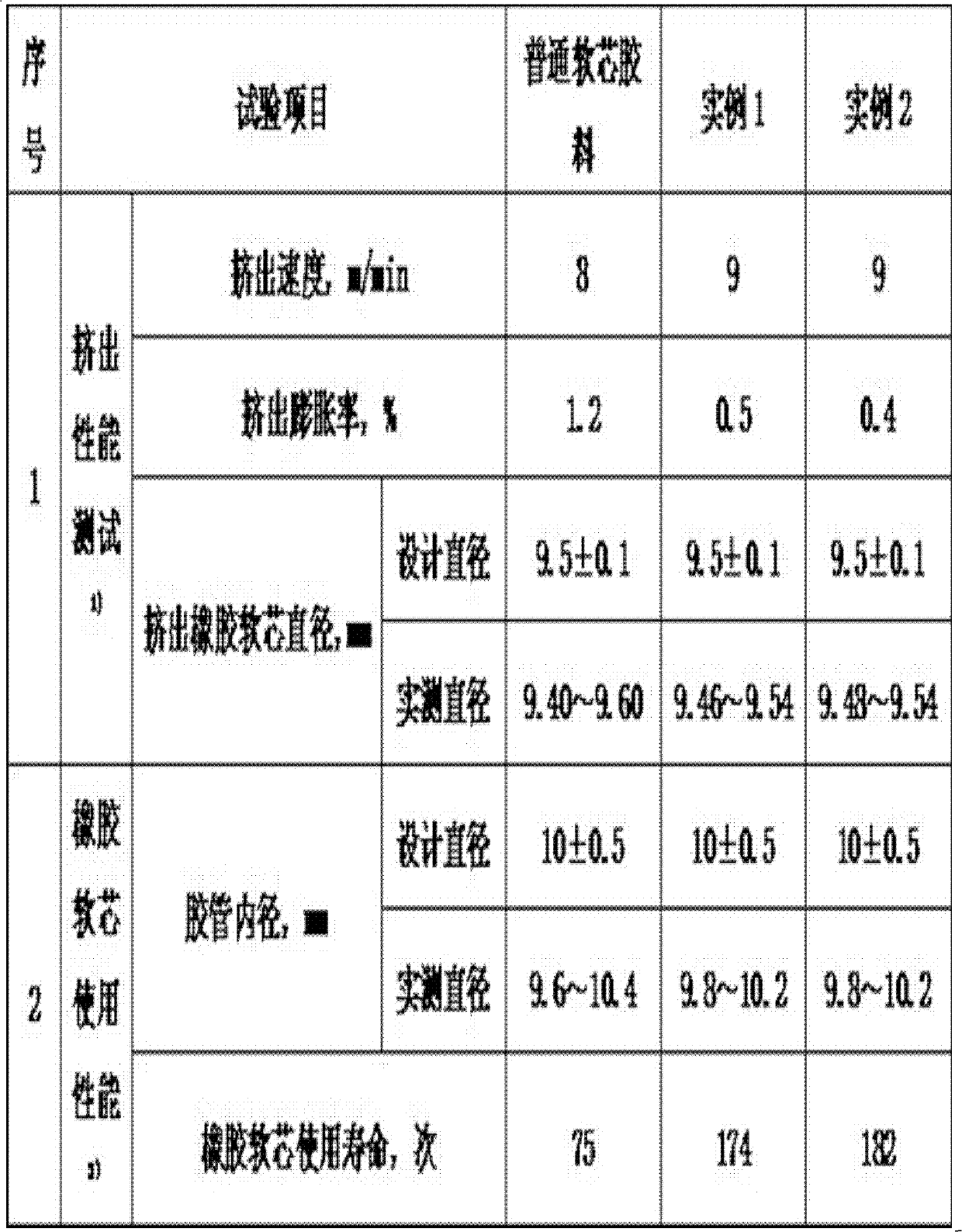

Examples

Embodiment Construction

[0008] Rubber hose is used to prepare raw materials with rubber soft core, and the dosage is as follows in parts by mass:

[0009] serial number

components

Example 1 / part

Example 2 / part

1

EPDM

100

100

2

6

8

3

1.5

2

4

Antiaging agent RD

2

1.5

5

Antiaging agent 4010NA

1.5

1.5

6

Paraffin

2

1.5

7

Tackifier A-90

2

2

8

Paraffin oil 2280

70

80

9

Carbon black N550

55

45

10

Carbon black N774

75

90

11

DCP

2

2.5

12

Accelerator TAIC

3

2.5

13

accelerator TBzTD

0.4

0.3

[0010] According to the above-mentioned preparation of raw materials and compounded rubber, Example 1 and Example 2 were vulcanized according to the vulc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com