End chain functional graphene modified intelligent energy cable, shielding material and manufacturing method thereof

A graphene modification, smart energy technology, applied in power cables, insulated cables, power cables with shielding layers/conducting layers, etc. Non-uniformity and other problems, to achieve the effect of improving the effect of the homogenizing electric field, increasing the amount of glue, and improving the safe operation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

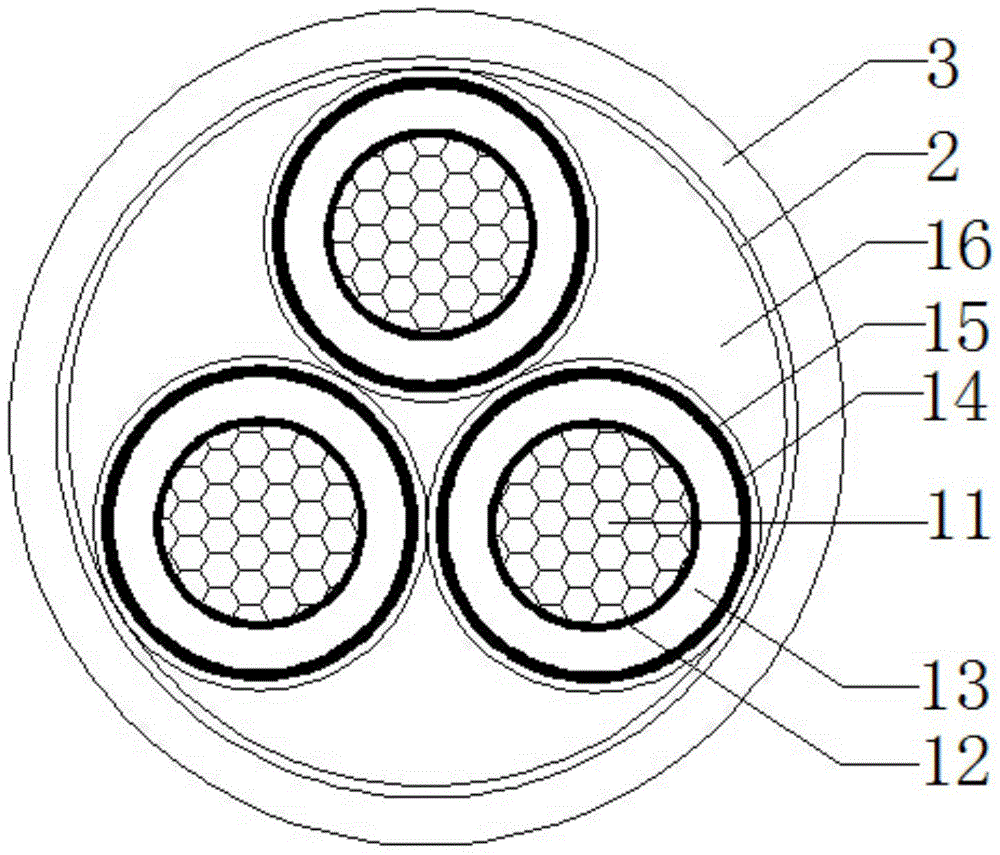

[0028] See figure 1 , a kind of end chain functionalized graphene modified smart energy cable of this embodiment, sequentially includes a cable core 1, a tape 2 and an outer sheath 3 from the inside to the outside; the cable core 1 includes three insulated cores; each insulated The wire core is followed by a conductor 11, an end-chain functionalized graphene modified conductor shielding layer 12, an insulating layer 13, an end-chain functionalized graphene modified insulating shielding layer 14 and a copper tape shielding layer 15 from the inside to the outside. Between the belts 2 is a filling layer 16; the end chain functionalized graphene modified conductor shielding layer 12, the insulating layer 13 and the end chain functionalized graphene modified insulating shielding layer 14 are a three-layer co-extruded structure. The graphene of the terminal chain functionalized graphene modified conductor shielding layer 12 and the terminal chain functionalized graphene modified ins...

experiment example 1

[0038]Put 100 parts of ethylene-vinyl acetate copolymer (EVA), 10 parts of functionalized graphene powder, 6 parts of lubricant, and 0.8 parts of antioxidant into the raw material bin respectively through the upper hopper, and at room temperature (20°C), add Into the mixing zone of the kneading extrusion granulation unit, stirring and mixing at a speed of 140-190rpm for 1-3 minutes to obtain a uniformly mixed mixture. The mixture is sent to the plasticizing zone of the kneading, extruding and granulating unit, and plasticized twice at different temperatures (screw speed 180rpm). The plasticized material is sent to the granulation area of the mixing extrusion granulation unit, under the condition of temperature about 110°C and pressure about 5.5Mpa, it is made into black granules of 5mm×5mm×5mm, and cooled to room temperature. The cooled particles are sent to the centrifugal dehydrator of the mixing, extruding and granulating unit, and dehydrated at a speed of about 1100rpm f...

experiment example 2

[0040] Put 100 parts of ethylene-vinyl acetate copolymer (EVA), 10 parts of graphene powder, 6 parts of lubricant, and 0.8 parts of antioxidant into the raw material warehouse through the upper hopper, and add them to the mixing chamber at room temperature (20°C). In the mixing zone of the refining extrusion granulation unit, stir and mix at a speed of 140-190rpm for 1-3 minutes to obtain a uniformly mixed mixture. The mixture is sent to the plasticizing zone of the kneading, extruding and granulating unit, and plasticized twice at different temperatures (screw speed 180rpm). The plasticized material is sent to the granulation area of the mixing extrusion granulation unit, under the condition of temperature about 110°C and pressure about 5.5Mpa, it is made into black granules of 5mm×5mm×5mm, and cooled to room temperature. The cooled particles are sent to the centrifugal dehydrator of the mixing, extruding and granulating unit, and dehydrated at a speed of about 1100rpm for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com