Environment-friendly flame-retardant modified hips LCD TV shell and preparation method thereof

An environment-friendly, LCD TV technology, applied in the field of HIPS LCD TV casing and its preparation, can solve the problems of poor mechanical properties and appearance quality, difficulty in uniform dispersion, human body and environmental hazards, etc., to improve production stability and finished products High efficiency, simple preparation method, good comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

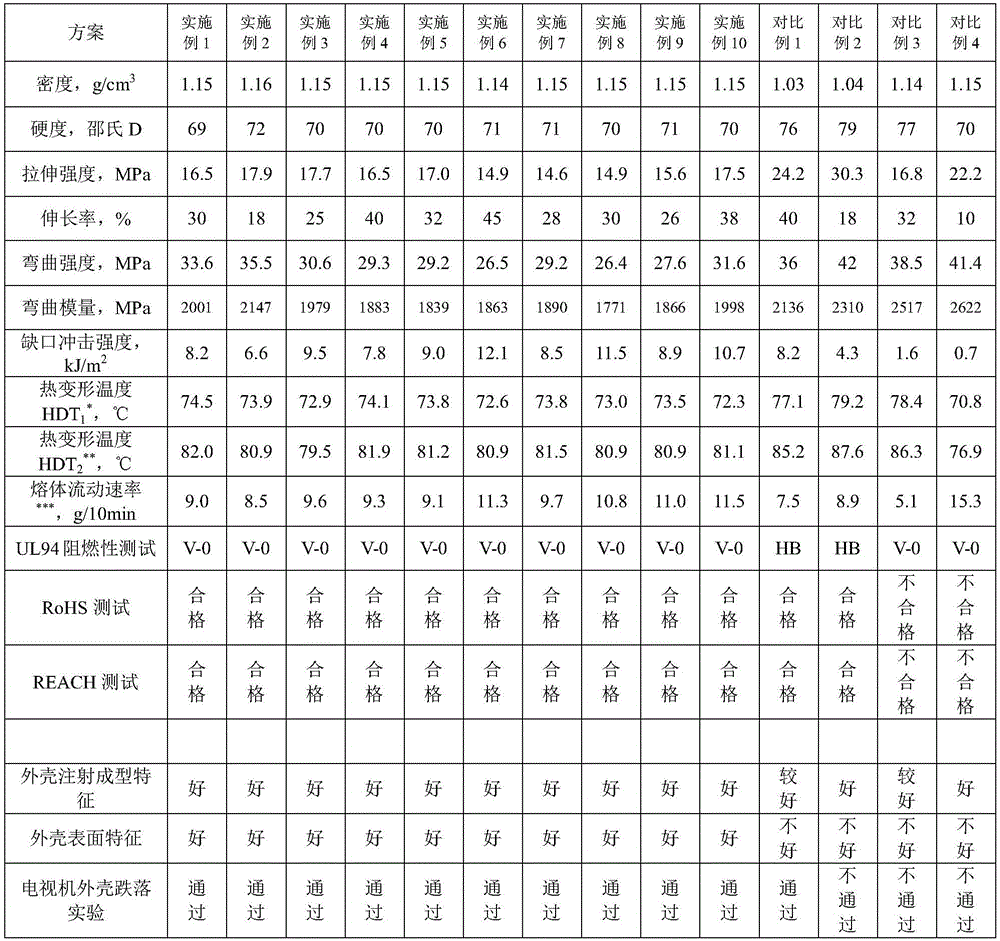

Embodiment 1

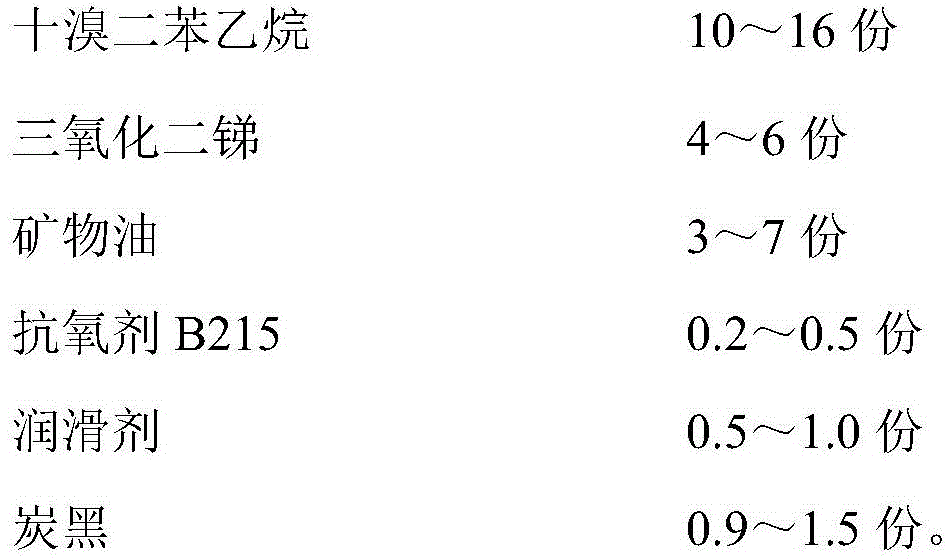

[0031] The mass ratio of raw materials is: HIPS resin (rubber mass fraction 6%, MFR=6.8g / 10min) 62.8, GPPS resin (MFR=9.6g / 10min) 10.2, thermoplastic styrene-butadiene rubber (mass ratio S / B=30 / 70 , MFR=0.5g / 10min) 5.5, decabromodiphenylethane 12.5, ultra-fine high-purity antimony trioxide 4.2, naphthenic oil (100 ° C kinematic viscosity = 10.5mm 2 / s) 4, antioxidant B2150.4, zinc stearate 0.3, ethylene bis stearic acid amide 0.2, carbon black (coloring strength 105%) 1.5.

[0032] Preparation:

[0033] ①Preparation of functional additive masterbatch: Soak carbon black pigment and mineral oil at room temperature for 42 hours, then add and grind 4 times in a three-roll mill with a roll temperature of 35°C to make a carbon black slurry with a particle size of 2.5-10 μm. Add thermoplastic styrene-butadiene rubber, decabromodiphenylethane, ultra-fine high-purity antimony trioxide, antioxidant B215, lubricant and carbon black slurry into the high-speed mixer, and start the low-spe...

Embodiment 2

[0037] The mass ratio of raw materials is: HIPS resin (rubber mass fraction 8%, MFR=4.8g / 10min) 40, GPPS resin (MFR=11.2g / 10min) 30, thermoplastic styrene-butadiene rubber (mass ratio S / B=20 / 80 , MFR=2.0g / 10min) 8, decabromodiphenylethane 12, ultra-fine high-purity antimony trioxide 6, naphthenic oil (100 ° C kinematic viscosity = 9mm 2 / s) 3, antioxidant B2150.3, zinc stearate 1.0, carbon black (coloring strength 118%) 1.2.

[0038] Preparation:

[0039]①Preparation of functional additive masterbatch: Soak carbon black pigment and mineral oil at room temperature for 40 hours, then add and grind 4 times in a three-roll mill with a roll temperature of 35°C to make a carbon black slurry with a particle size of 2.5-10 μm. Add thermoplastic styrene-butadiene rubber, decabromodiphenylethane, ultra-fine high-purity antimony trioxide, antioxidant B215, lubricant and carbon black slurry into the high-speed mixer, and start the low-speed mixer below 500rpm in the high-speed mixer. St...

Embodiment 3

[0043] The mass ratio of raw materials is: HIPS resin (rubber mass fraction 6%, MFR=6.8g / 10min) 52, HIPS resin (rubber mass fraction 8%, MFR=4.8g / 10min) 11, GPPS resin (MFR=9.6g / 10min) 10min) 10, thermoplastic styrene-butadiene rubber (mass ratio S / B=30 / 70, MFR=1.0g / 10min) 5, decabromodiphenylethane 16, ultrafine high-purity antimony trioxide 4, naphthenic oil ( Kinematic viscosity at 100℃=15mm 2 / s) 5, antioxidant B2150.2, polyethylene wax 0.3, ethylene bis stearic acid amide 0.3, carbon black (coloring strength 121%) 0.9.

[0044] Preparation:

[0045] ①Preparation of functional additive masterbatch: Soak carbon black pigment and mineral oil at room temperature for 45 hours, then add and grind three times in a three-roll mill with a roll temperature of 45°C to make a carbon black slurry with a particle size of 5-10 μm. Add thermoplastic styrene-butadiene rubber, decabromodiphenylethane, ultra-fine high-purity antimony trioxide, antioxidant B215, lubricant and carbon black ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com