Environment-friendly flame-resistant ABS resin

An ABS resin and environmental protection technology, applied in the field of flame-retardant polymer materials, can solve the problems of unfriendly environment, low smoke generation, environmental and human hazards, etc., and achieve the effect of reducing environmental and human hazards and small smoke generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

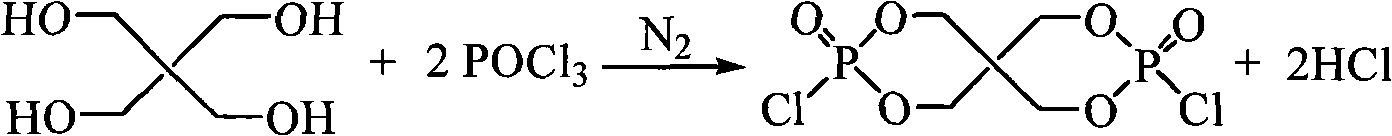

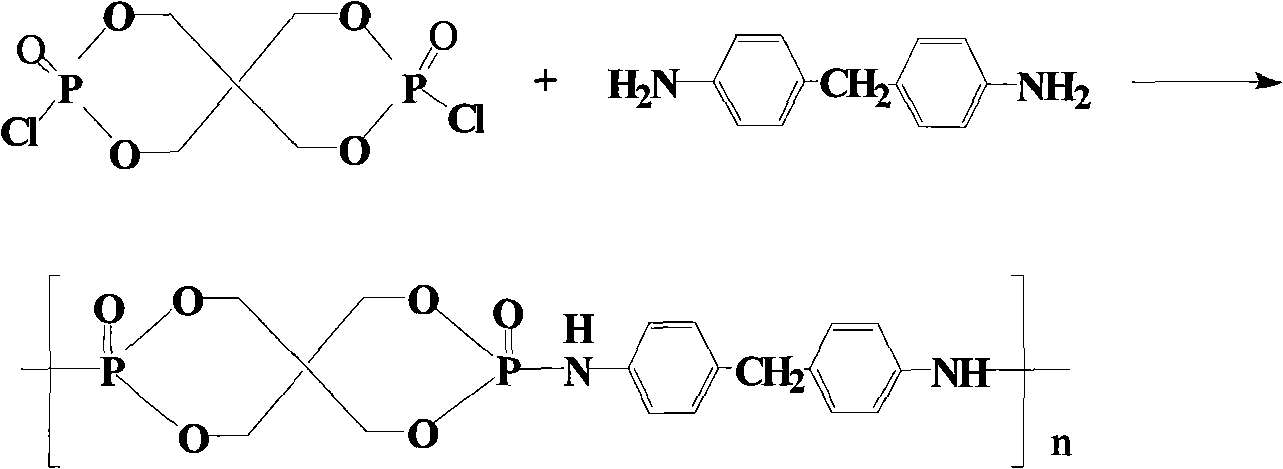

Method used

Image

Examples

Embodiment

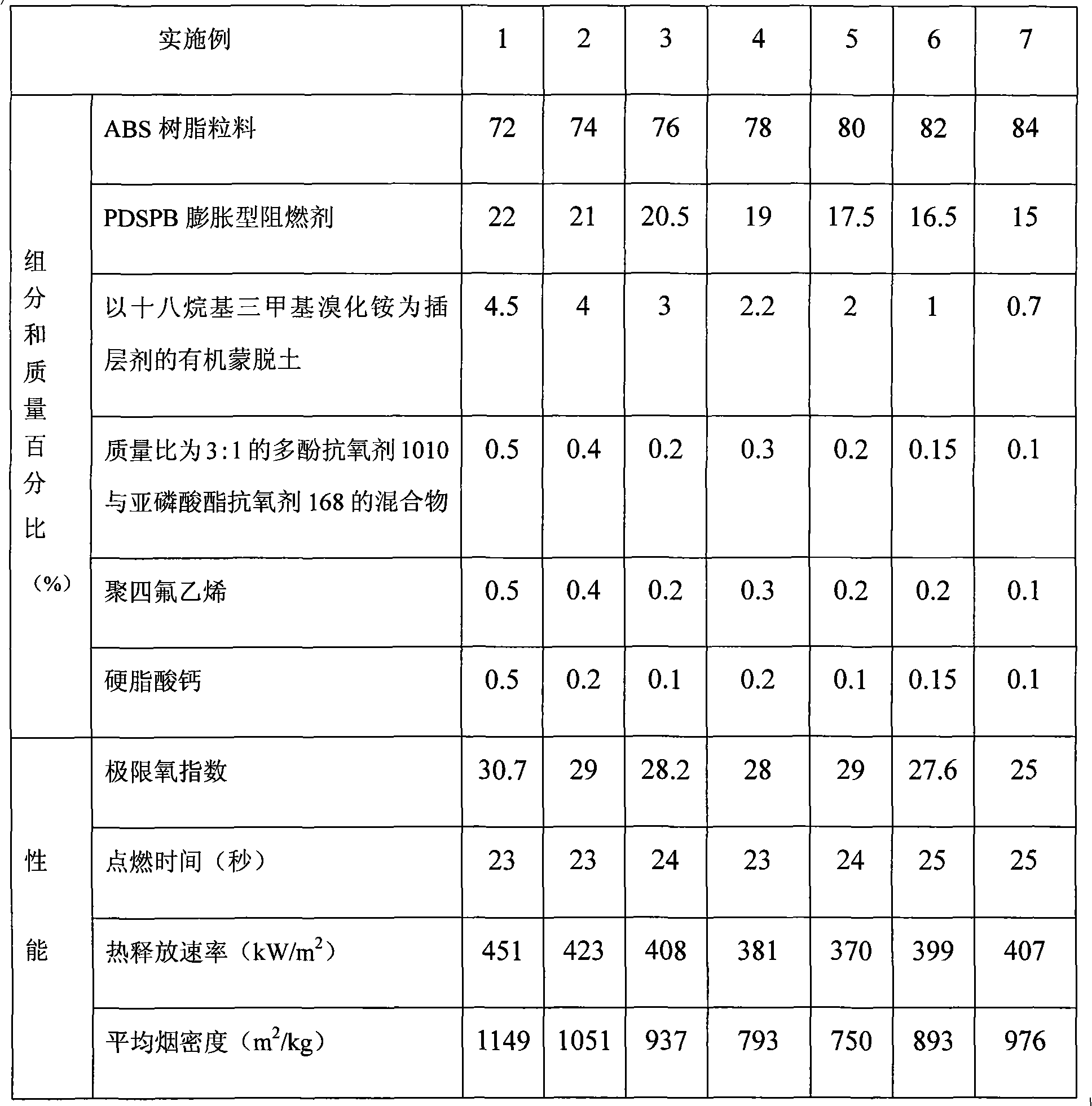

[0019] The preparation method of the environmentally friendly flame-retardant ABS resin sample of the embodiment of the present invention is as follows: the ABS resin pellets, the prepared PDSPB intumescent flame retardant, and montmorillonite (with octadecyl Trimethylammonium bromide is organic montmorillonite as intercalation agent), antioxidant (a mixture of polyphenol antioxidant 1010 and phosphite antioxidant 168 with a mass ratio of 3:1), anti-dripping agent (polytetrafluoroethylene) and lubricant (calcium stearate) are pre-mixed in a high-speed mixer according to the formula ratio to obtain a premix; , the premix is added to the twin-screw extruder, and the material extruded from the extruder is cooled, pelletized and packaged to finally obtain the environmentally friendly flame-retardant ABS resin of the present invention.

[0020] The mass percent of each component of the embodiment of the present invention and its product properties are shown in Table 1:

[0021] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com