Manufacturing method of high-performance environment-friendly domestic wire

A manufacturing method and high-performance technology, applied in the direction of cable/conductor manufacturing, circuits, conductive materials, etc., can solve the problems of low overload capacity and non-environmental protection of ordinary home improvement wires, and achieve excellent performance, low power consumption, and strong overload capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

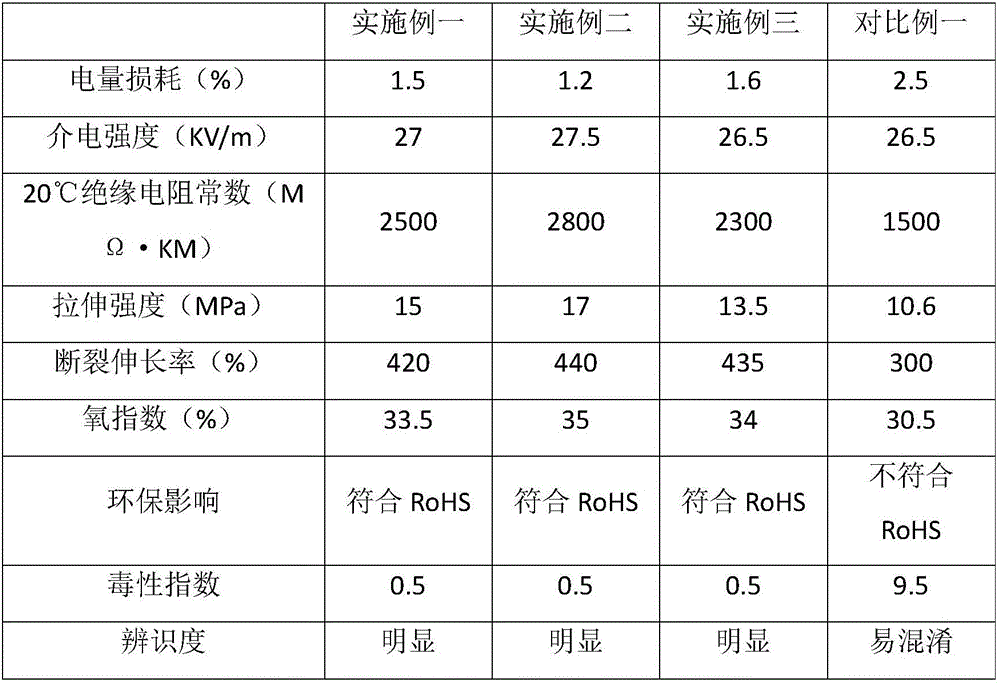

Examples

Embodiment 1

[0020] Example 1, a manufacturing method of a high-performance environmentally friendly home improvement wire, including the steps of wire drawing, co-extrusion, testing, coiling and warehousing, adopts copper single wire or stranded wire with a purity greater than 99.98% as the core material, and the surface insulation material includes inner Layer insulation material and outer layer insulation material, inner layer insulation material and outer layer insulation material are all PVC insulation materials, PVC insulation material is composed of 100kg polyvinyl chloride, 35kg p-phenylene, 5kg liquid calcium zinc stabilizer, 8kg kaolin, 20kg calcium It is composed of powder, and the outer insulating material is added with 1kg of pigment.

[0021] Wire drawing is carried out by continuous drawing and annealing of the copper rod, after multiple passes of drawing; the drawing speed of the last drawing is 1200m / min; or the stranding process is carried out to form a copper stranded wir...

Embodiment 2

[0026] Embodiment 2, the difference between this embodiment and embodiment 1 is that the PVC insulating material is composed of 100kg polyvinyl chloride, 42kg p-phenylene, 7kg liquid calcium zinc stabilizer, 11kg kaolin, and 28kg calcium powder, and the outer insulating material is increased by 1.5 kg of pigment, the temperature in the middle section of the extruder is about 150°C during co-extrusion, and the temperature at the head is about 175°C.

Embodiment 3

[0027] Embodiment 3, the difference between this embodiment and embodiment 1 is that the PVC insulating material is composed of 100kg polyvinyl chloride, 48kg p-phenylene, 8kg liquid calcium zinc stabilizer, 15kg kaolin, and 35kg calcium powder, and the outer insulating material is increased by 1.5 kg of pigment, the temperature in the middle section of the extruder is about 165°C during co-extrusion, and the temperature at the head is about 180°C.

[0028] The calcium powder that adopts in the above-mentioned embodiment is that heavy calcium carbonate and light calcium carbonate form by the ratio of mass ratio 2:1. Heavy calcium carbonate, referred to as heavy calcium, is ground from natural carbonate minerals such as calcite, marble, and limestone. Light calcium carbonate, also known as precipitated calcium carbonate, referred to as light calcium, is to burn limestone and other raw materials to produce lime and carbon dioxide, then add water to digest the lime to produce mil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com