Halogen-free flame-retardant environment-friendly epoxy electronic encapsulating material

An environmentally friendly and encapsulating material technology, which is applied in the field of new electronic chemical materials, halogen-free flame-retardant and environmentally friendly epoxy electronic encapsulating materials, can solve the problems of low heat resistance and breakdown strength, which affect the quality and export of electronic products , low flame retardancy and other issues, to achieve excellent flame retardancy, good flame retardancy, and good temperature shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

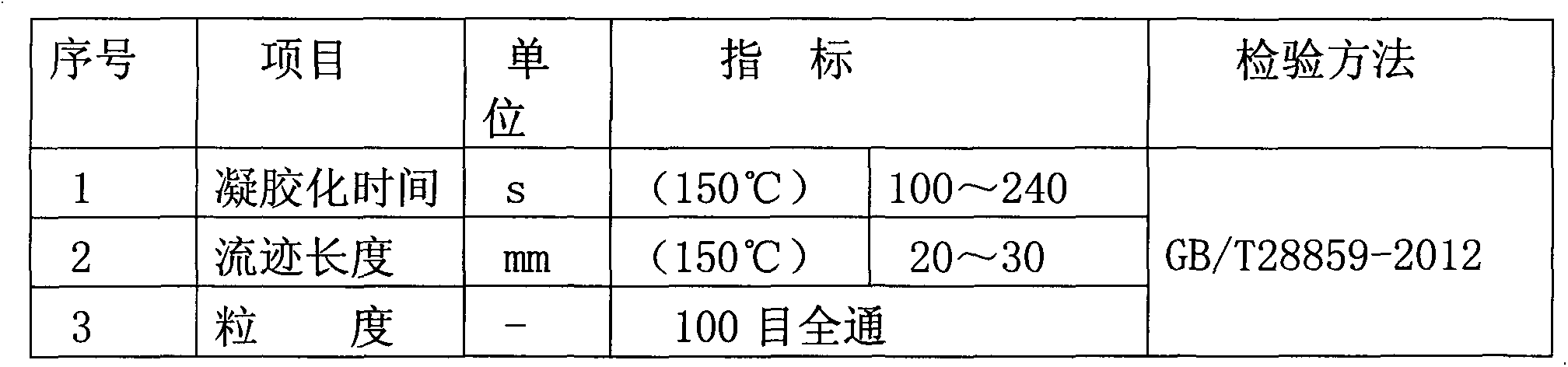

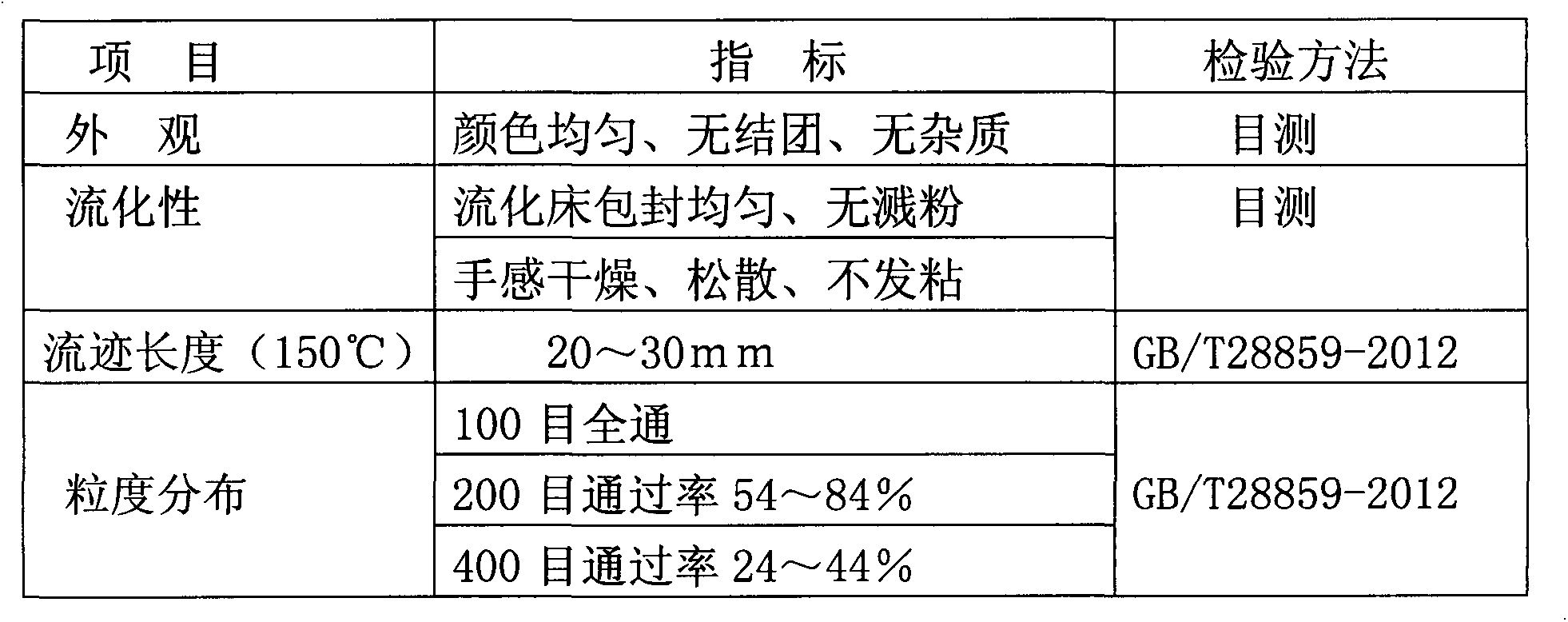

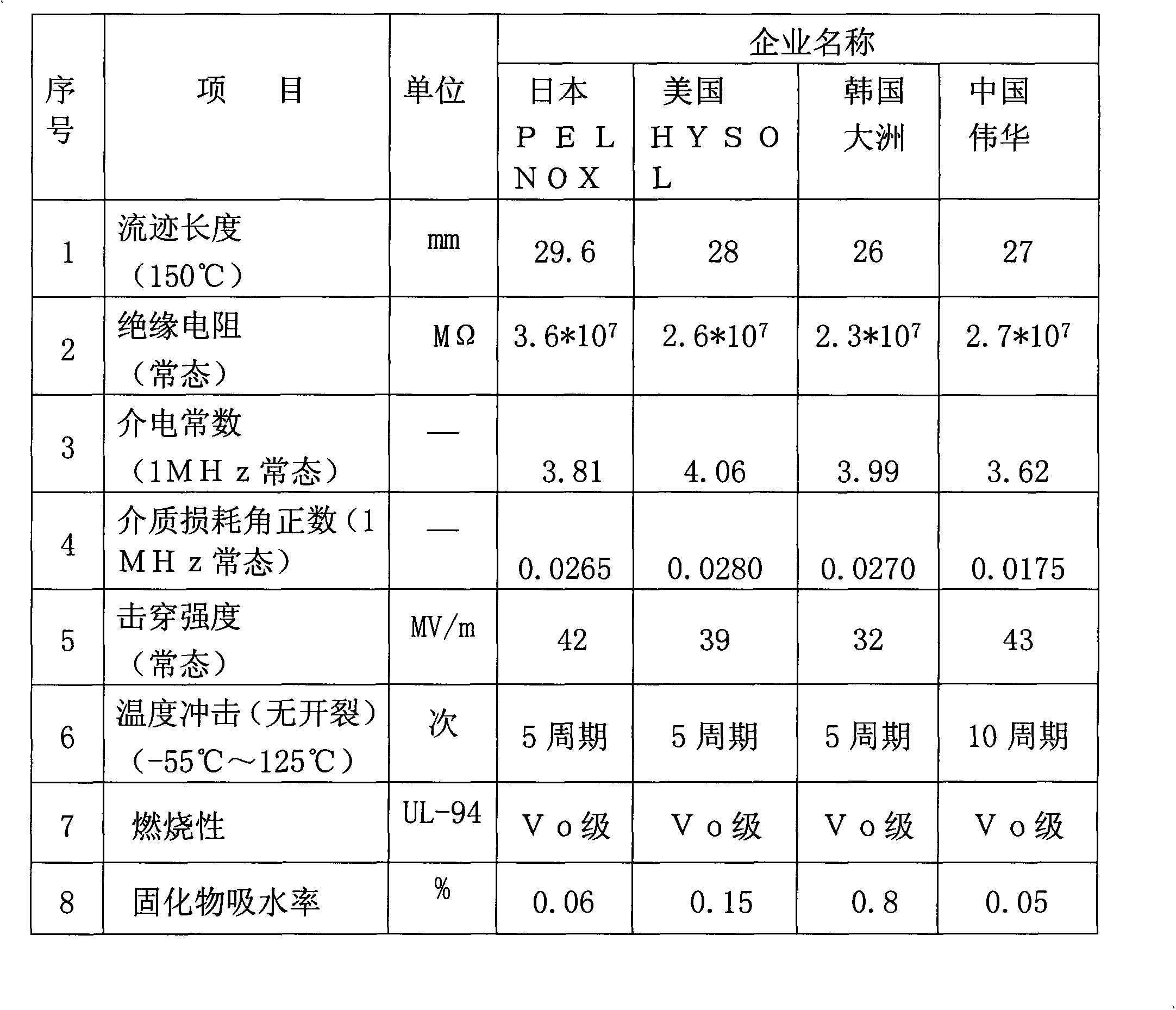

[0015] Halogen-free flame-retardant and environment-friendly epoxy electronic encapsulation material is mainly composed of epoxy resin, silica powder, curing agent, 2-methylimidazole, halogen-free flame retardant, leveling agent, pigment, copper oxalate eight kinds of substances mixed, It is a thermosetting powder electronic encapsulation compound made by kneading and extruding, cooling and pressing, crushing and grading, remixing and sieving. Wherein the percentage by weight of various main substances is: epoxy resin: silicon micropowder: curing agent: 2-methylimidazole: halogen-free flame retardant: leveling agent: pigment: copper oxalate=40-43: 40-42: 5 :0.2:3-4:1:2:2.8.

[0016] Yueyang Petrochemical CYD-014U was selected as the epoxy resin, DHG600 mesh was selected as the silicon powder, and Xi'an Dahe PSG-02 was selected as the curing agent.

[0017] The production method of the halogen-free flame-retardant and environment-friendly epoxy electronic encapsulation compoun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com