Pretreatment method of polybrominated biphenyls and poly brominated diphenyl ethers in nylon resin and nylon resin products

A polybrominated diphenyl ether and polybrominated biphenyl technology, applied in the field of analytical chemistry, can solve the problems of high solvent consumption, low recovery rate and high extraction temperature, and achieve the effect of improving the method recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

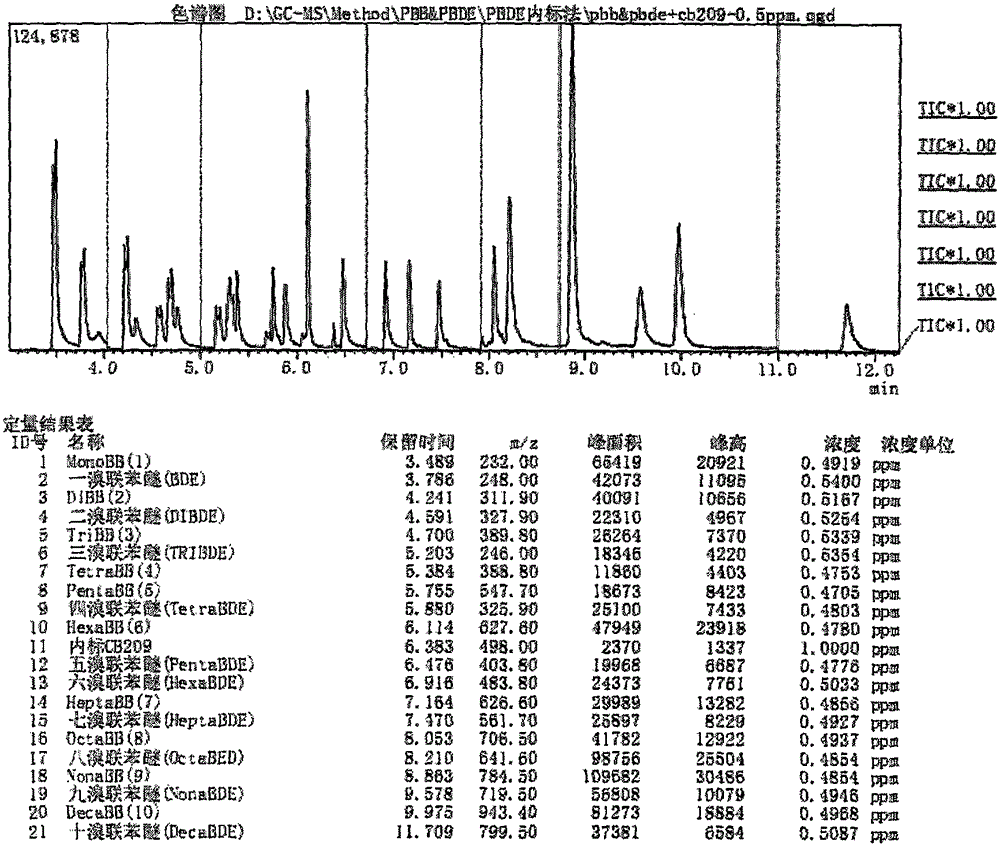

Image

Examples

Embodiment 1

[0012] 1. Reagents and equipment:

[0013] Reagents: phenol (analytically pure), toluene (chromatographically pure), methanol (chromatographically pure); materials: 20ml stoppered test tube, filter paper, funnel, 25ml volumetric flask, 5ml graduated pipette, nylon resin sample; instrument: grinder, available Temperature adjustment ultrasonic extraction machine, analytical balance.

[0014] 2. Operation steps:

[0015] (1) Take a representative sample and shred it with scissors to a size of 5 mm. During the crushing process, the sample should be avoided from contamination.

[0016] (2) Grind the chopped samples with a high-speed grinder until the particle size is less than 0.5 mm (cool the samples with liquid nitrogen for 5 minutes if necessary).

[0017] (3) Accurately weigh two parallel samples that are uniformly crushed, 0.1 g (accurate to 0.1 mg) of each sample, and place them in two 20 ml stoppered test tubes respectively.

Embodiment 2

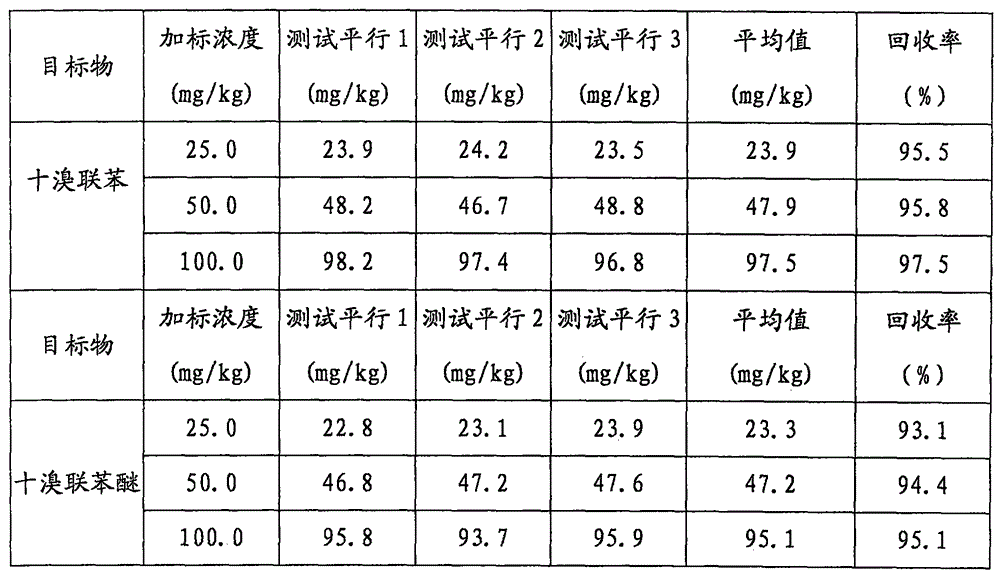

[0023] Add decabromobiphenyl and decabromodiphenyl ether to the negative nylon resin particles where polybrominated biphenyls and polybrominated diphenyl ethers are not detected, so that the theoretical spiked concentrations in the sample are: 25.0mg / kg, 50.0mg / kg, 100.0 mg / kg, according to the above sample pretreatment method and instrumental analysis detection method to carry out the experiment. The sample of each spiked concentration was measured in parallel three times, and the average value of the three measurements was taken. According to the amount of reagent added and the measured results, the spiked recovery rate of the sample was calculated. The experimental results are shown in Table 1. It can be seen from Table 1 that the recovery rate of the sample addition is between 92-100%. The detection recovery and analytical precision fully meet the experimental requirements.

[0024] Table 1 The recovery rate of standard addition of nylon resin

[0025]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com