Screening and application of polybrominated diphenyl ethers (PBDEs) degrading bacterium

A technology of polybrominated diphenyl ethers and BDE209, which is applied in the direction of bacteria, microorganism-based methods, water/sludge/sewage treatment, etc., to achieve good degradation ability, simple operation process, and low requirements for management conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

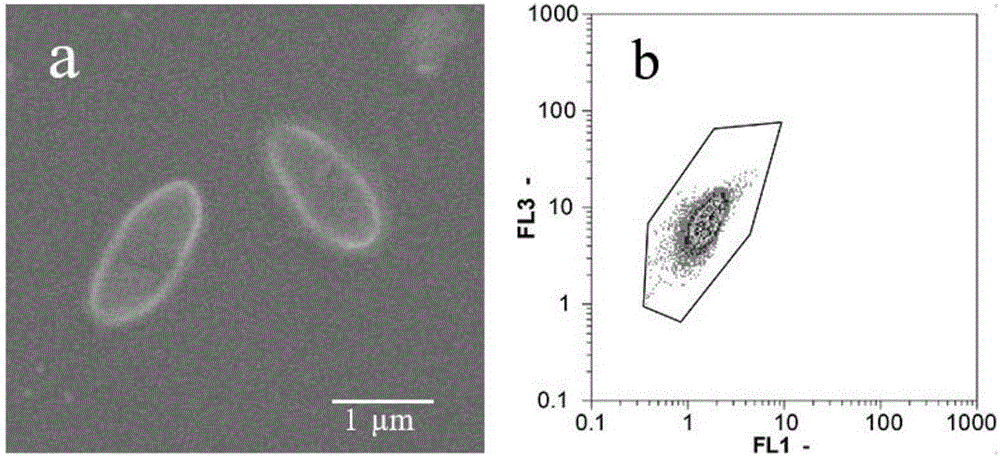

[0036] Embodiment 1, the screening of Stenotrophomonas

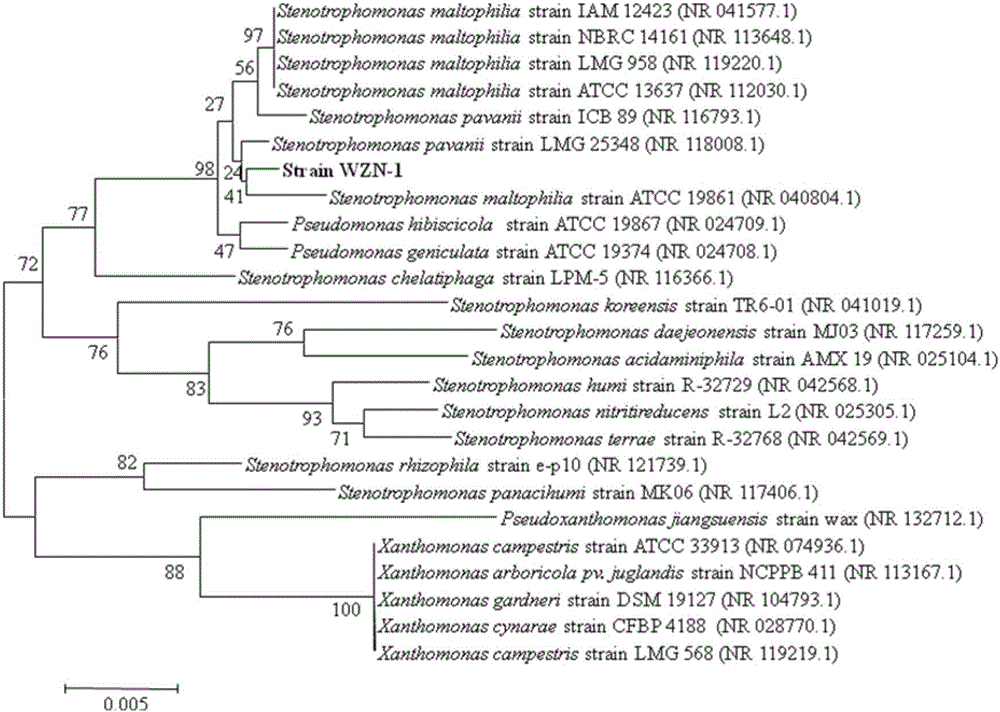

[0037] Weigh 5-10g of soil samples contaminated by polybrominated diphenyl ethers (PBDEs) and add them to 50-100mL of high-temperature sterilized 0.85% normal saline, vortex fully, let stand for 10-30 minutes, and take 5mL of soil supernatant Pass through a 0.45μm filter membrane, transfer 1mL of the filtrate to an inorganic salt medium with 10mg / L BDE 209 as the sole carbon source, and culture in a constant temperature shaker at 30°C, 150r / min, and transfer once a week to make BDE 209 The final concentration reached 30mg / L. After 3 weeks of cultivation, the bacterial strains were isolated and purified on the LB solid medium by streaking method, and the dominant colony with faster growth was selected, and the purification was repeated 3 times to obtain a single pure colony. After expanded culture in liquid LB medium, the whole gene of the strain was extracted, PCR amplified, 16rDNA sequencing was performed, and the seque...

Embodiment 2

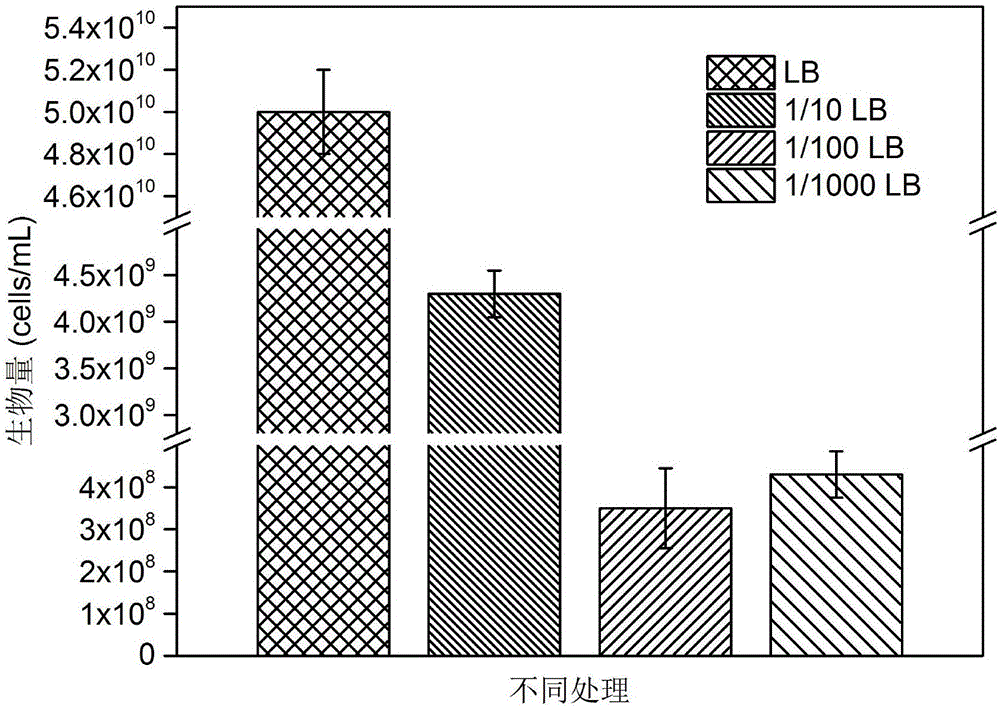

[0040] Determination of Growth of Stenotrophomonas in Different Concentrations of LB

[0041] After the bacterial strain screened in Example 1 was inoculated into the LB liquid medium to expand the culture, 5 × 10 4 cells / mL were transferred to new LB medium, samples were taken at 0, 4, 12, 23, 30, and 36 hours respectively, and the uninoculated LB medium was used as the blank control, and the bacterial growth was detected by flow cytometry, and the obtained Growth of Stenotrophomonas in different concentrations of LB. image 3 Stenotrophomonas in different concentrations of LB, respectively LB, 10-fold diluted LB (1 / 10LB), 100-fold diluted LB (1 / 100LB) and 1000-fold diluted LB (1 / 1000LB) for 36 hours It can be seen that the strain has good utilization of different concentrations of LB, and within 36 hours, the maximum growth in different concentrations reached 5.0×10 10 ,4.3×10 9 ,3.5×10 8 ,4.3×10 8 cells / mL.

Embodiment 3

[0043] Optimal Conditions for Degradation of BDE209 by Stenotrophomonas

[0044] Orthogonal experiment was used to select 5 factors pH, temperature, salinity, medium volume, BDE209 concentration, and set 5 levels respectively, pH (5, 7, 8, 9, 11), temperature (20°C, 25°C, 30℃, 35℃, 40℃), salinity (0%, 0.5%, 1%, 2%, 4%), medium volume (50mL, 100mL, 150mL, 200mL, 250mL), BDE209 concentration (50μg / L , 100μg / L, 250μg / L, 500μg / L, 750μg / L), optimize the degradation conditions of BDE209 by Stenotrophomonas. The experiment consisted of 25 treatments, each treatment was repeated 3 times, and the degradation time was 7 days. The results showed that the optimal degradation conditions for BDE209 by Stenotrophomonas were pH 5, temperature 25°C, and salinity 0.5%. The volume of the medium was 150 mL, and the concentration of BDE209 was 500 μg / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com