Method for separating antimony and arsenic from antimony and arsenic-containing ash through oxidation and alkaline leaching

A technology of oxidizing alkali leaching and soot, which is applied in the field of smelting special metals antimony and arsenic, which can solve the problems of extremely high operating process requirements, secondary pollution, and poor operating process conditions, and achieve simple process, high-efficiency separation, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

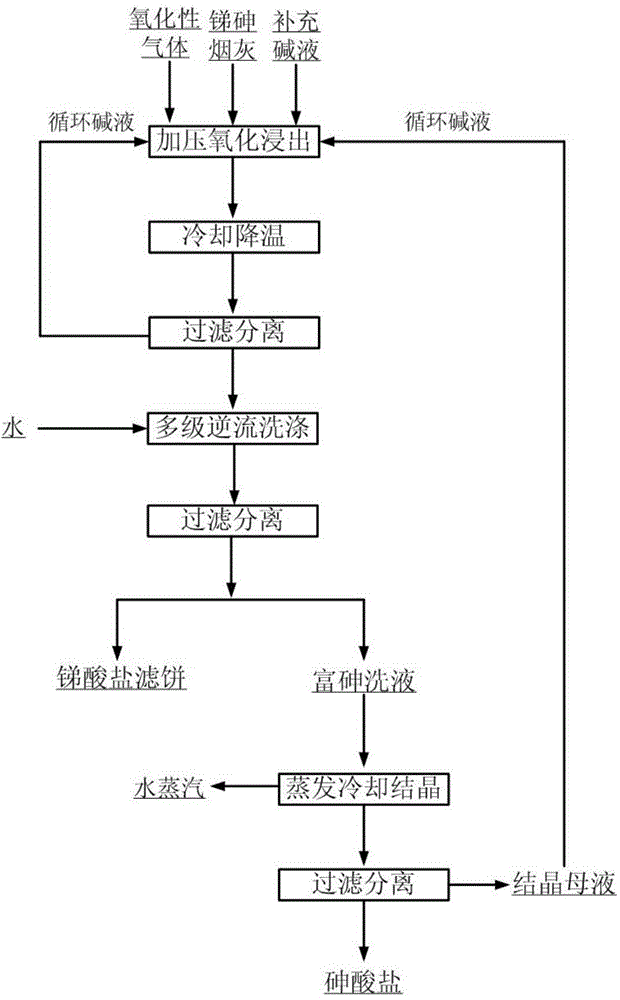

[0014] The method for separating the arsenic of antimony in the soot of antimony and arsenic by oxidation alkali leaching of the present embodiment comprises the following steps:

[0015] (1) Prepare a NaOH solution with an alkali concentration of 400g / L, mix the antimony-arsenic soot (including Sb32.23%, As36.22%) and NaOH solution according to the liquid-solid ratio of 9:1, and place it in an alkali-resistant high-pressure reaction Heat and stir in the kettle; when the temperature of the slurry reaches 250°C, inject 1.0MPa of oxygen into the reaction kettle, and start timing. After reacting for 2 hours, cool the slurry to below 90°C to obtain the reaction-completed slurry;

[0016] (2) The slurry is filtered and separated after the reaction is completed, and the filtrate is returned to the pressurized alkaline leaching process for the next batch of antimony-arsenic soot;

[0017] (3) Wash the filter cake obtained in step (2) with multi-stage countercurrent washing with hot w...

Embodiment 2

[0021] The method for separating the arsenic of antimony in the soot of antimony and arsenic by oxidation alkali leaching of the present embodiment comprises the following steps:

[0022] (1) Prepare a NaOH solution with an alkali concentration of 480g / L, mix the antimony-arsenic soot (including Sb43.66%, As21.97%) and NaOH solution according to the liquid-solid ratio of 5:1, and place it in an alkali-resistant high-pressure reaction Heat and stir in the kettle; when the temperature of the slurry reaches 90°C, feed 1.8MPa oxygen into the reaction kettle, and start timing. After 3 hours of reaction, the reaction-completed slurry is obtained;

[0023] (2) The slurry is filtered and separated after the reaction is completed, and the filtrate is returned to the pressurized alkaline leaching process for the next batch of antimony-arsenic soot;

[0024] (3) The filter cake obtained in step (2) is subjected to multistage countercurrent washing with hot water at 80 to 90° C., and filt...

Embodiment 3

[0028] The method for separating the arsenic of antimony in the soot of antimony and arsenic by oxidation alkali leaching of the present embodiment comprises the following steps:

[0029] (1) Prepare a NaOH solution with an alkali concentration of 600g / L, mix the antimony-arsenic soot (including Sb15.16%, As46.29%) and NaOH solution according to the liquid-solid ratio of 3:1, and place it in an alkali-resistant high-pressure reaction Heat and stir in the kettle; when the temperature of the slurry reaches 150°C, inject 1.5MPa of oxygen into the reaction kettle, and start timing. After reacting for 1 hour, cool the slurry to below 90°C to obtain the reaction-completed slurry;

[0030] (2) The slurry is filtered and separated after the reaction is completed, and the filtrate is returned to the pressurized alkaline leaching process for the next batch of antimony-arsenic soot;

[0031] (3) Wash the filter cake obtained in step (2) with multi-stage countercurrent washing with hot wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com