Inorganic thermal insulation material and preparation method thereof

A technology of inorganic thermal insulation material and coupling agent, which is applied in the field of inorganic thermal insulation material and its preparation, can solve the problems of high cost of supercritical technology, and achieve the effects of reduced thermal conductivity, high tensile strength and flexural strength, and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The invention provides a preparation method of an inorganic thermal insulation material, comprising the following steps: A) adding 15-60wt% silica airgel, 15-60wt% soluble silicate, 15-40wt% formula (I ) structure compound, 5-15wt% tin antimony oxide and 5-15wt% hollow glass microspheres are mixed, and modified by adding a coupling agent to obtain a mixture; B) the mixture is mixed with water, and the obtained slurry is infiltrated into the glass Inorganic thermal insulation material is obtained by thermoforming on the fiber mat;

[0043] (I);

[0044] Wherein, 1≤n≤24, preferably 6≤n≤18, X is F, Br or Cl, preferably Br or Cl.

[0045] The silica airgel can be silica airgel well-known to those skilled in the art, and there is no special limitation. Both the supercritical drying method and the solvent replacement method can reduce the surface tension of the solvent so as to obtain air condensation. Glue products, the difference is that the product obtained by the supe...

Embodiment 1

[0080] 1.1 Adjust the pH value of 200g of silica sol to 6 with 1mol / L hydrochloric acid, slowly add 100mL of ethanol, and keep it in a water bath at 50°C for 24 hours to obtain a wet gel.

[0081] 1.2 Put the wet gel obtained in 1.1 in 500ml of ethanol, soak at 50°C for 24 hours, soak twice continuously, then add 300mL of a mixed solution of tetraethyl orthosilicate and ethanol, soak for 48 hours for aging, and then use 500mL Soak in ethanol for 24 hours, and soak twice in succession to obtain alcohol gel, in which the volume ratio of ethyl orthosilicate to ethanol is 1:4.

[0082] 1.3 Mix the alcohol gel obtained in 1.2 with 7g of formamide, and dry it in an oven at 70°C for 72 hours to obtain a silica airgel.

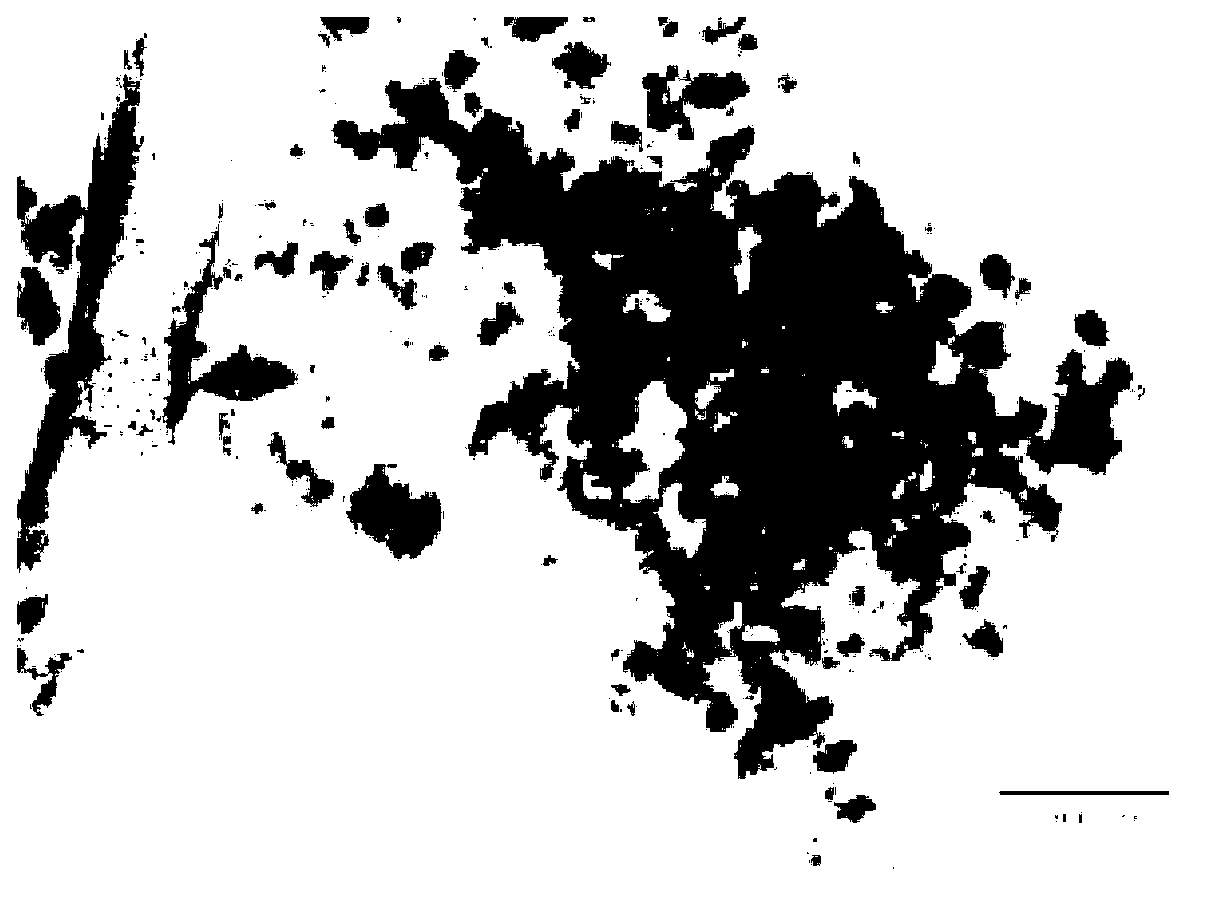

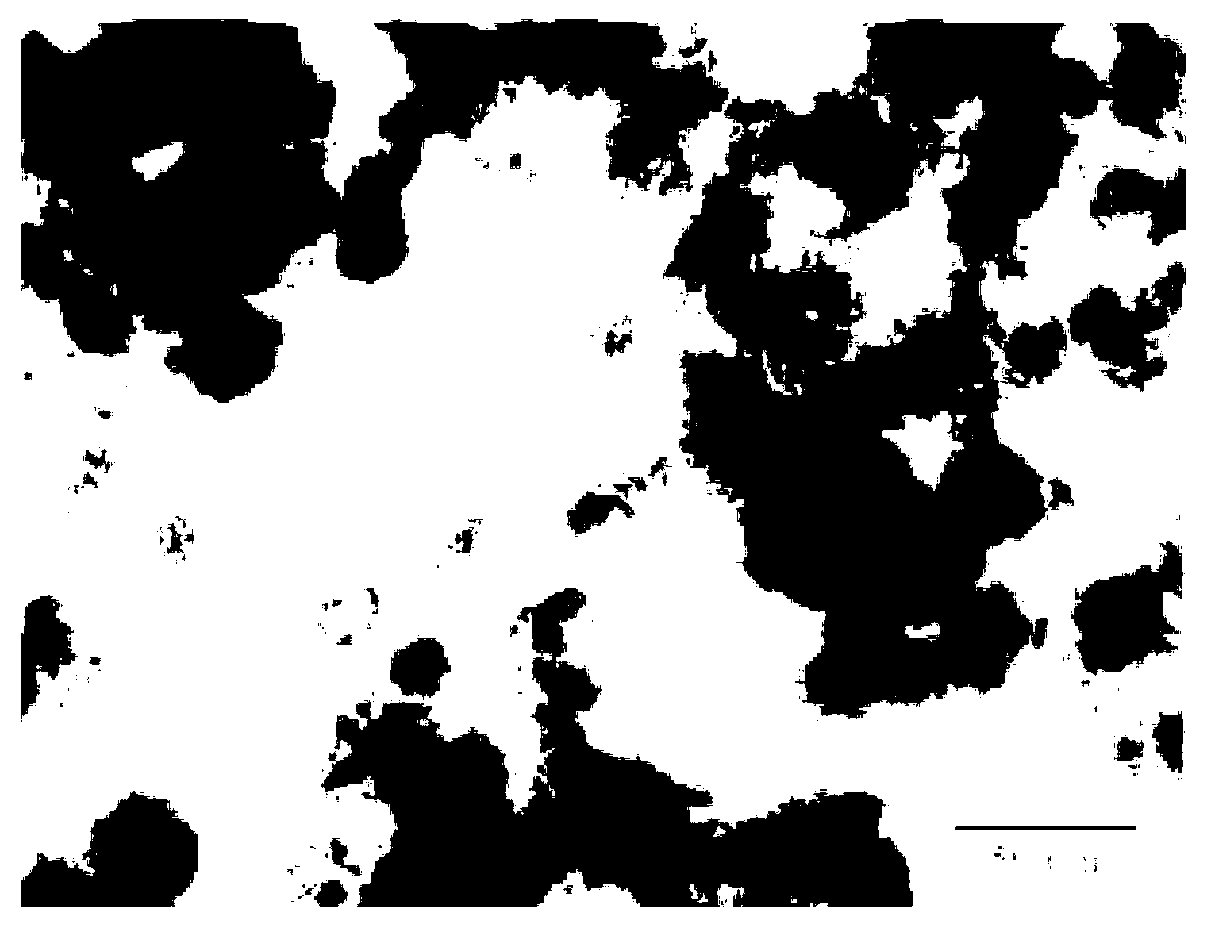

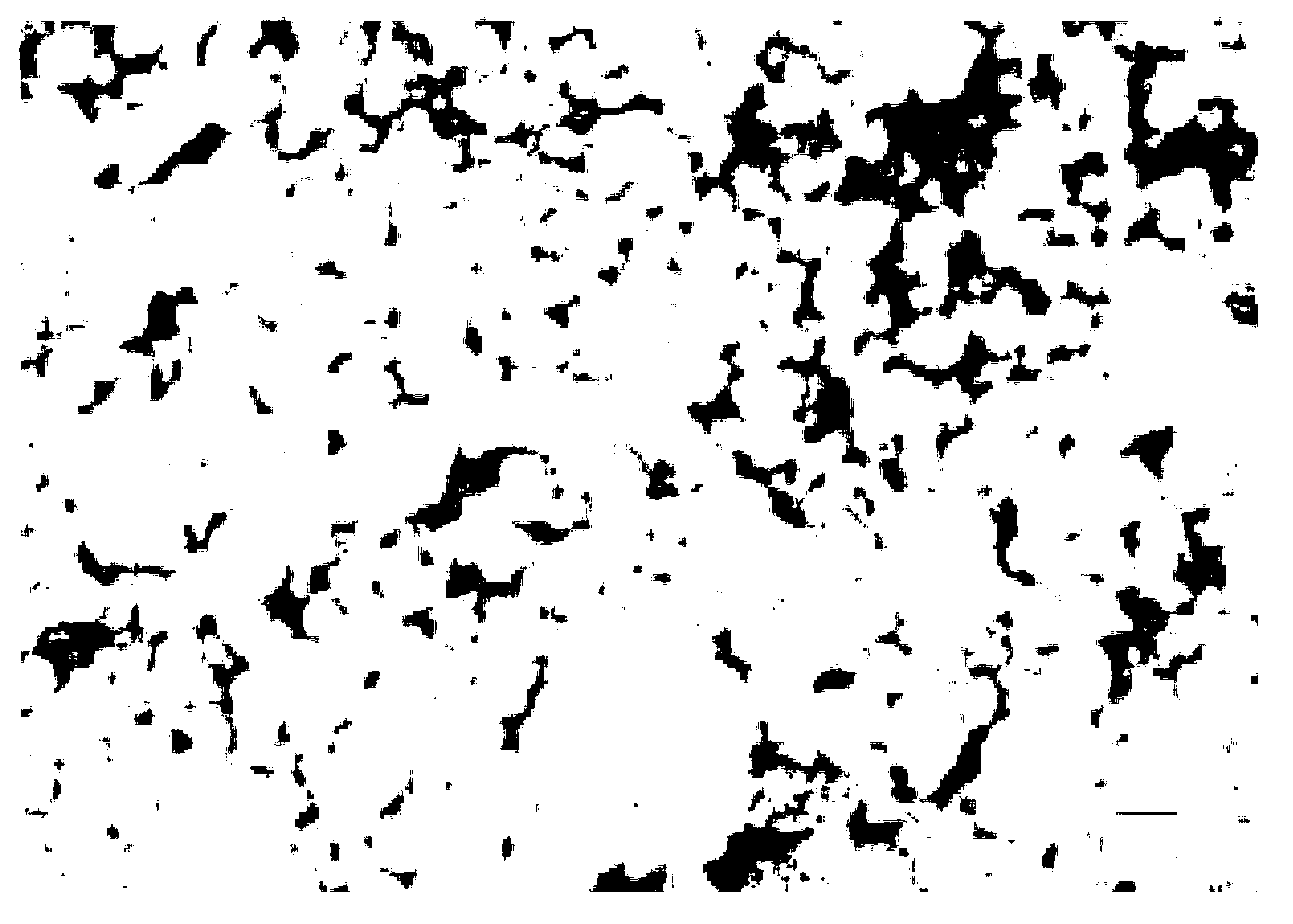

[0083] After grinding and ultrasonically dispersing the silica airgel obtained in 1.3, analyze it with a transmission electron microscope, and obtain its transmission electron micrograph, as shown in figure 1 and figure 2 as shown, figure 1 It is a 100nm level tra...

Embodiment 2

[0089] Mix 500g of the silica airgel obtained in Example 1 with 250g of silane coupling agent, stir for 30min, add 150g of potassium silicate, 150g of dodecyltrimethylammonium chloride, 50g of antimony tin oxide and 50g of Mix the hollow glass microspheres evenly, add 5L of water and stir for 30min until uniform to obtain a slurry. Spray the slurry evenly on 8 pieces of 30cm×30cm, 0.4cm thick glass fiber mats with spraying grout, and then hot press molding under the conditions of pressure 100MPa and temperature 80°C to obtain inorganic thermal insulation materials.

[0090] According to GB / T8624-2006, the combustion performance test of the inorganic thermal insulation material obtained in Example 2 is carried out, and the results obtained are shown in Table 1.

[0091] According to GB / T20473, the inorganic thermal insulation material obtained in Example 2 was tested for compressive strength, compressive shear bond strength and dry apparent density, and the results are shown in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com