Intelligent nano transparent insulating glass coating

A technology of thermal insulation and glass coating, applied in the direction of coating, etc., can solve the problems of high cost, limited energy-saving effect, and inconspicuous thermal insulation effect, and achieve the effects of low production cost, improved energy-saving effect, and strong weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

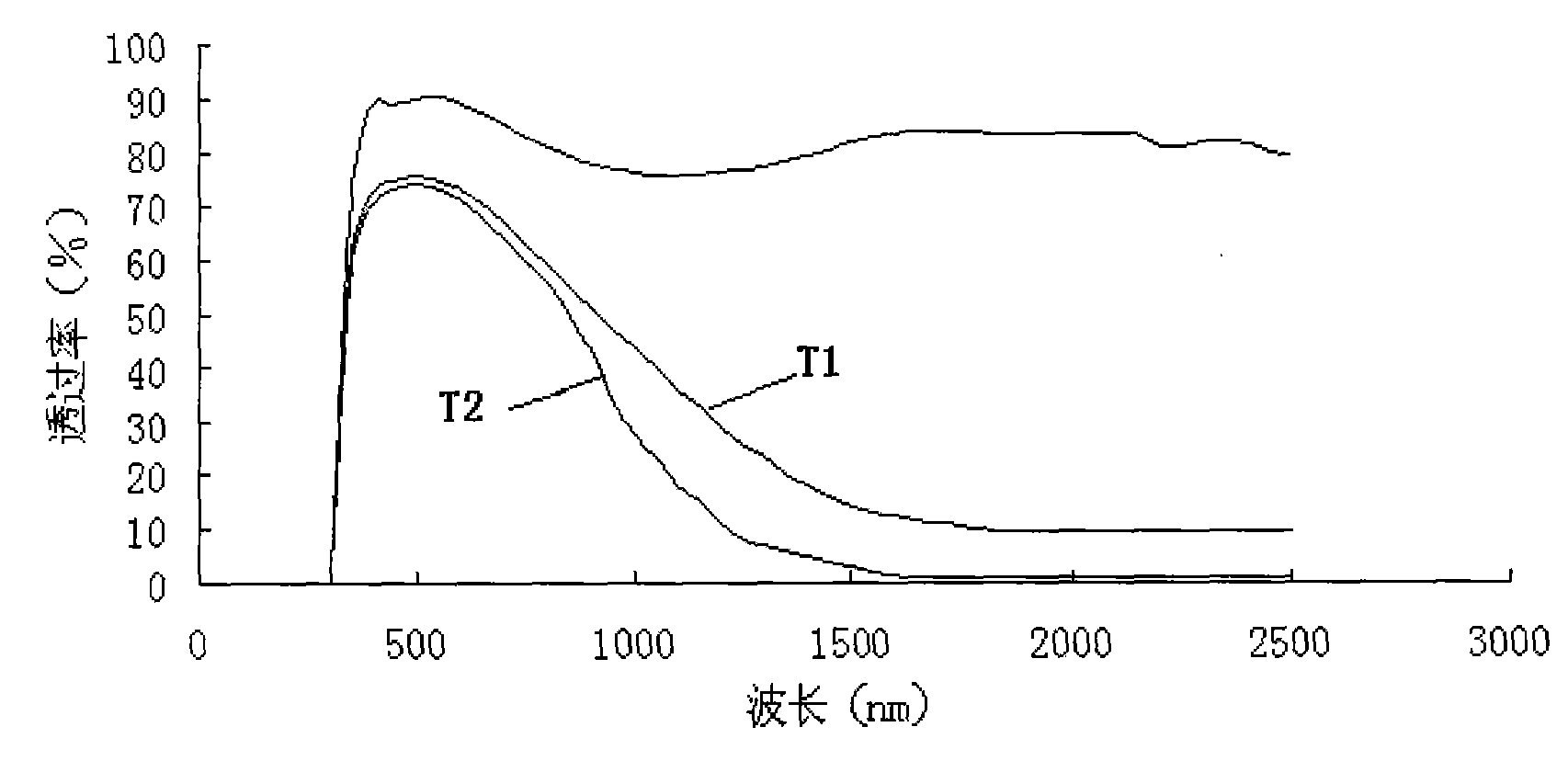

Embodiment 1

[0062] It is composed of silicone resin, nano-indium tin oxide slurry, nano-silicon dioxide slurry, doped nano-vanadium dioxide slurry, butyl acetate, polyether modified organic silicon compound: Flomax 6510, and the following weight ( %) proportioning is prepared:

[0063] Silicone resin 24%;

[0064] Nano Indium Tin Oxide Paste 45%;

[0065] Nano silica slurry 10%;

[0066] Doped nano vanadium dioxide slurry 15%;

[0067] Butyl acetate 5%;

[0068] Polyether modified organosilicon compound: Flomax 6510 1%.

[0069] The process of preparing intelligent nano-transparent thermal insulation glass coating is: first prepare nano-indium tin oxide slurry, nano-silicon dioxide slurry, and nano-vanadium dioxide-doped slurry, and then mix nano-indium tin oxide slurry, Silicon oxide slurry, doped nano-vanadium dioxide slurry, butyl acetate and polyether modified organosilicon compound: Flomax 6510 was added dropwise to the silicone resin, and stirred for 30 minutes to obtain a synt...

Embodiment 2

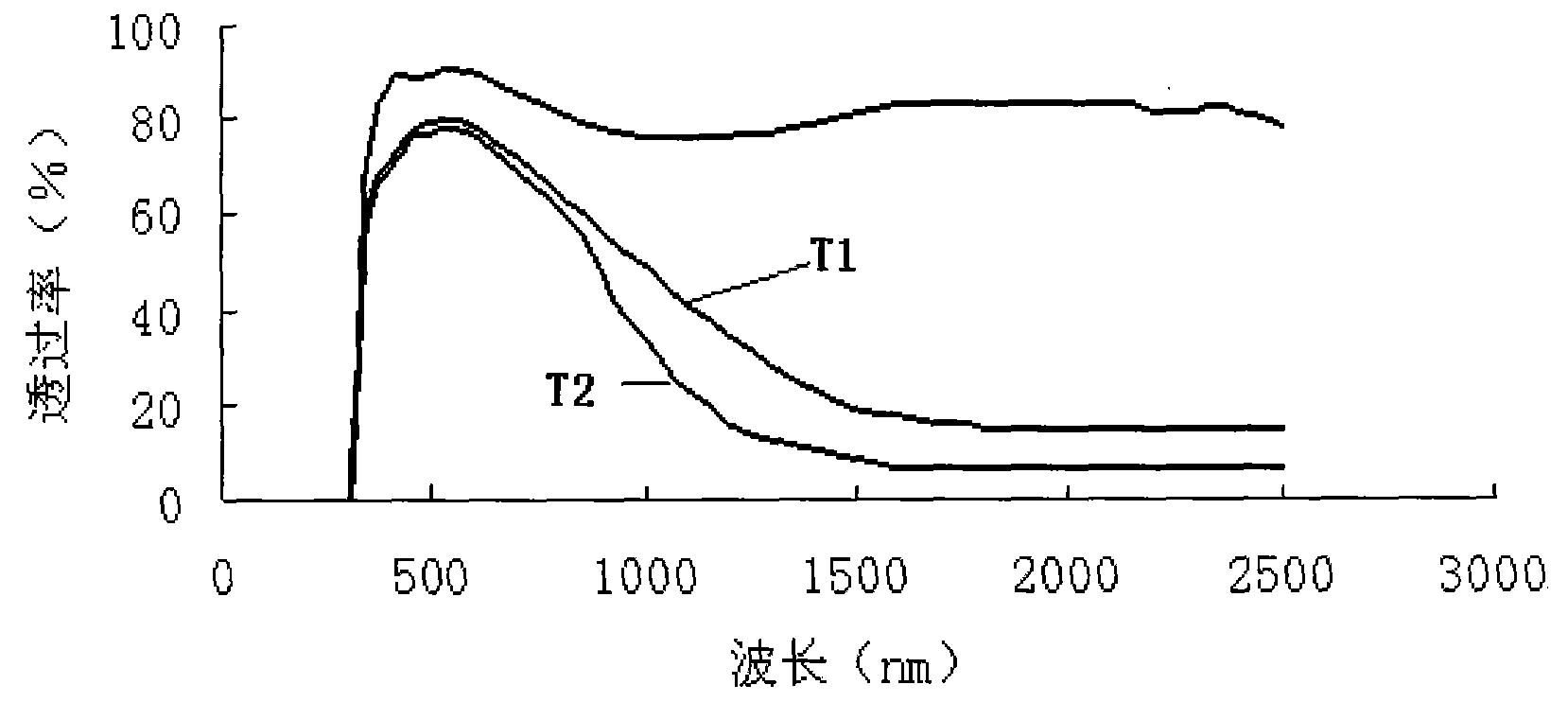

[0093] It is composed of silicone resin, nano-tin antimony oxide slurry, nano-aluminum oxide slurry, doped nano-vanadium dioxide slurry, butyl acetate, modified polysiloxane: HT-010, and the following weight (%) proportioning is prepared:

[0094] Silicone resin 40%;

[0095] Nano antimony tin oxide paste 40%;

[0096] Nano-alumina paste 8%;

[0097] Doped nano vanadium dioxide slurry 10%;

[0098] Butyl acetate 1%;

[0099] Modified polysiloxane: HT-010 1%.

[0100] The process of preparing intelligent nano-transparent thermal insulation glass coating is: first prepare nano-tin antimony oxide slurry, nano-aluminum oxide slurry, and nano-vanadium dioxide-doped slurry; Aluminum oxide slurry, doped nano-vanadium dioxide slurry, butyl acetate and modified polysiloxane: HT-010 were added dropwise to the silicone resin, and stirred for 25 minutes to obtain a synthetic intelligent nano-transparent insulation Insulating glass coating. Then take the prepared coating and apply it ...

Embodiment 3

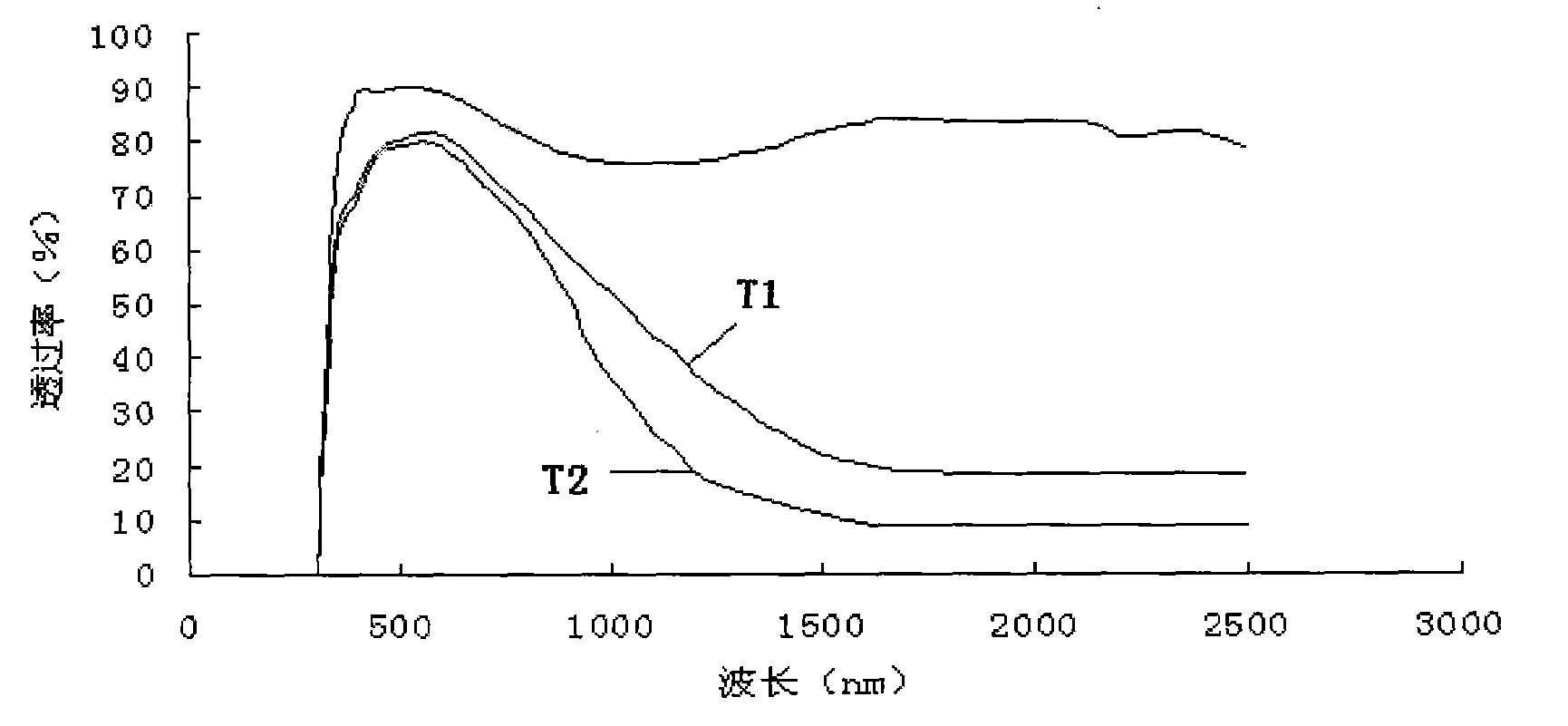

[0114] It is composed of silicone resin, nano-indium tin oxide slurry, nano-silicon dioxide slurry, doped nano-vanadium dioxide slurry, ethyl acetate, polyether modified organosilicon compound DC-57, and the following weight ( %) proportioning is prepared:

[0115] Silicone resin 50%;

[0116] Nano Indium Tin Oxide Paste 30%;

[0117] Nano silica slurry 6%;

[0118] Doped nano vanadium dioxide slurry 10%;

[0119] Ethyl acetate 3%;

[0120] Polyether modified organosilicon compound DC-57 1%.

[0121] The process of preparing intelligent nano-transparent thermal insulation glass coating is: first prepare nano-indium tin oxide slurry, nano-silicon dioxide slurry, and nano-vanadium dioxide-doped slurry, and then mix nano-indium tin oxide slurry, Silica slurry, doped nano-vanadium dioxide slurry, ethyl acetate and polyether modified organosilicon compound: DC-57 was added dropwise to the silicone resin, and stirred for 20 minutes to obtain a synthetic intelligent nano-transpa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com