Glass powder and its preparation method and conductive paste for solar cell

A glass powder and raw material technology, which is applied to conductive materials, circuits, and electrical components dispersed in non-conductive inorganic materials, can solve problems such as environmental hazards, lead in glass powder, and low photoelectric conversion efficiency, and achieve cost savings, The effect of easy source and high photoelectric conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026]The present invention provides the preparation method of above-mentioned glass powder, comprises the following steps:

[0027] Step 1. Mix the weighed glass powder raw materials evenly; in this step, the glass powder raw materials are oxide powders, and the oxide powders include bismuth oxide, titanium oxide, zinc oxide, antimony oxide, containing or Does not contain tellurium oxide, contains or does not contain molybdenum oxide and selenium oxide powder, based on the total weight of the glass powder raw materials, the weight percentage of each component is: bismuth oxide: 30 wt%-70 wt%; Titanium: 1 wt%-20 wt%; Zinc oxide: 5 wt%-40 wt%; Antimony oxide: 5 wt%-30 wt%; Tellurium oxide: 0 wt%-30 wt%; Molybdenum oxide: 0 wt%- 10 wt%; selenium oxide: 0 wt%-15 wt%. Preferably, the weight percentage of each component is: Bismuth oxide: 30 wt%-60 wt%; Titanium oxide: 5 wt%-10 wt%; Zinc oxide: 5 wt%-30 wt%; Antimony oxide: 5 wt% wt%-20 wt%; molybdenum oxide: 1 wt%-8wt%, seleniu...

Embodiment 1

[0039] (1) Preparation of glass powder

[0040] Referring to Table 1-3, take by weighing 100g of glass powder raw materials, including: 50g bismuth oxide, 5g titanium oxide, 20g zinc oxide, 5g antimony oxide, 10g tellurium oxide, 5g molybdenum oxide, 5g selenium oxide, the above glass Mix the powder raw materials evenly, pour them into a crucible, put them into a sintering furnace, raise the temperature to 1250°C, keep them warm for 2 hours, then pour the melted glass frit into cold water for water quenching, then put them into a ball mill, and add 1g of sodium silicate and 2g of ethyl cellulose were ball milled for 24 hours, and dried to obtain glass powder A1 with a particle size of 2.5 microns;

[0041] (2) Preparation of conductive paste

[0042] Get the organic vehicle (containing 0.5-6wt% of ethyl cellulose, 30-75wt% of terpineol, 10-50wt% of dibutyl phthalate (DBP), butyl carboxylacetate, which accounts for 15wt% of the total amount of conductive paste must alcohol 0-...

Embodiment 2-5

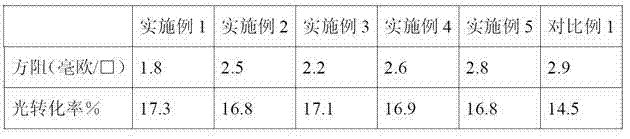

[0044] Adopt the method identical with embodiment 1 to prepare glass powder and conductive paste, difference is raw material and its proportioning, and process parameter, see Table 1 and Table 2 for details, and Table 1 is the proportioning of glass powder raw material; Table 2 is Process parameters: Glass powder A2-A5 and conductive paste B1-B5 were obtained through Examples 2-5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com