Antimony sulfide concentrate oxygen-enriched melting tank melting method

An oxygen-enriched molten pool smelting and antimony sulfide technology, applied in the field of antimony sulfide concentrate oxygen-enriched molten pool smelting, to achieve the effect of eliminating antimony matte phase, good quality of antimony white, and improving recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

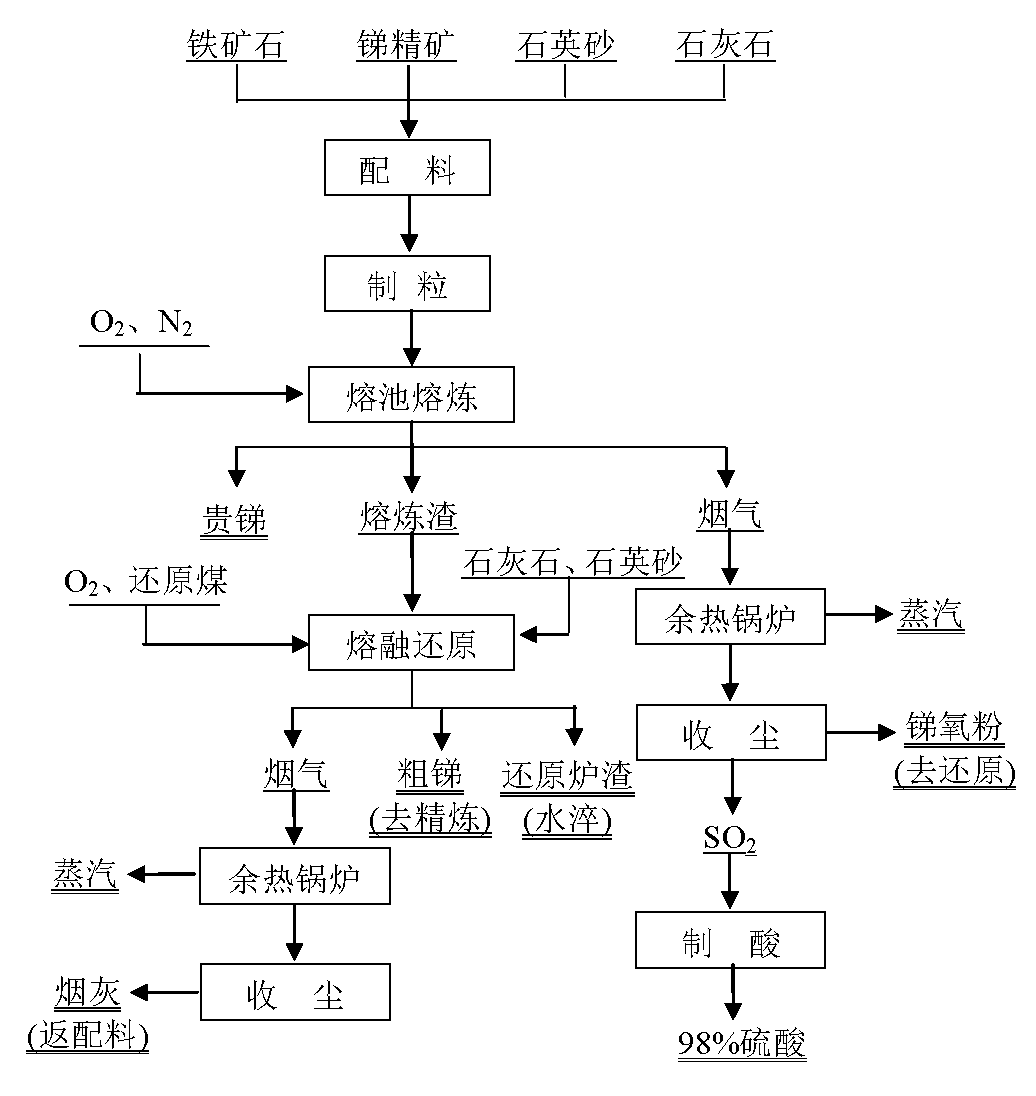

Image

Examples

Embodiment 1

[0083] The hearth size is 1600×2500mm and the hearth area is 4m 2 Experiments were carried out in a side-blown furnace.

[0084] Preparation:

[0085] Mix antimony concentrate with limestone, quartz sand and iron ore crushed to less than 20mm. The mass percentage of Sb in the mixed material is 25%, of which SiO 2 , FeO, and CaO mass percentages are 26%, 28%, 9% respectively, and sulfur mass percentage is 19%; add water to the above materials in a cylinder granulator until the material moisture is 8%, and make the particle size The pellets of 5mm~18mm are ready for use.

[0086] Oxidation smelting:

[0087] Add the above-mentioned spherical pellets into the above-mentioned side-blown furnace at a feeding rate of 10t / h, control the melting temperature between 1050-1300°C, and oxygen-enriched air blasted into the main tuyeres 2 The concentration is 70%, the rest is N 2 , the pressure of oxygen-enriched air is 0.8MPa, and the flow rate of oxygen-enriched air is 3500Nm 3 / h, ...

Embodiment 2

[0091] Design a φ1600×2000 bottom blowing furnace, set an oxygen lance at the bottom of the furnace, and conduct experiments in this furnace.

[0092] Preparation:

[0093] The antimony concentrate is mixed with limestone, quartz sand and iron ore crushed to less than 20mm. The mass percentage of Sb in the mixed material is 33%, of which SiO 2 , FeO, and CaO mass percentages are 20%, 22%, 10% respectively, and sulfur mass percentage content is 16%; add water to the above materials in a cylinder granulator until the material moisture is 10%, and make the particle size The pellets of 5mm~22mm are ready for use.

[0094] Oxidation smelting:

[0095] Add the above pellets into the above bottom blowing furnace at a feeding rate of 300kg / h, control the melting temperature between 1000~1200°C, blow industrial oxygen and industrial nitrogen with a purity greater than 99% from the oxygen lance, oxygen and Nitrogen pressure is 0.4MPa, oxygen flow rate is 75m 3 / h, nitrogen flow rate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com