Device and method for producing stannic oxide through self-heating way

A tin dioxide and self-heating technology, applied in tin oxide and other directions, can solve the problems of high relative cost, high technical requirements, and high equipment investment, and achieve stable and reliable equipment operation, improve product quality, and ensure the effect of purity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

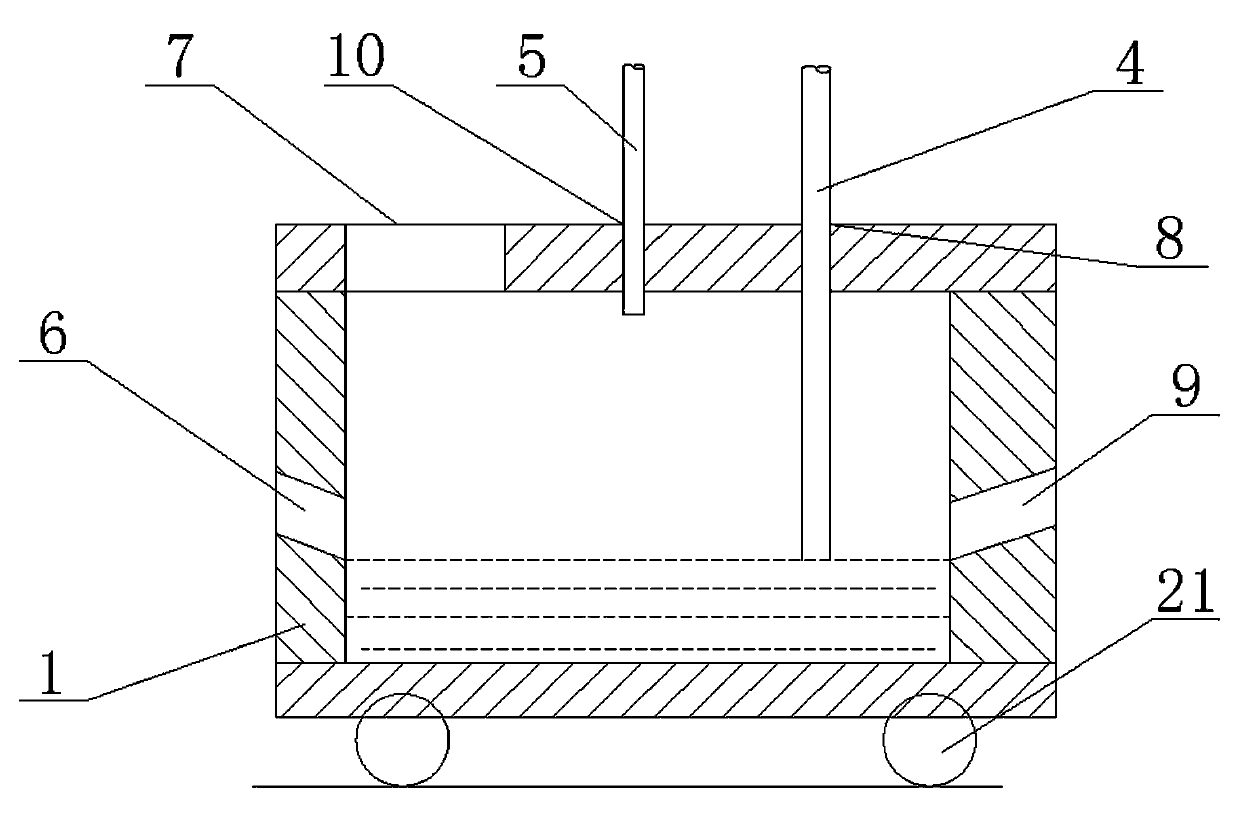

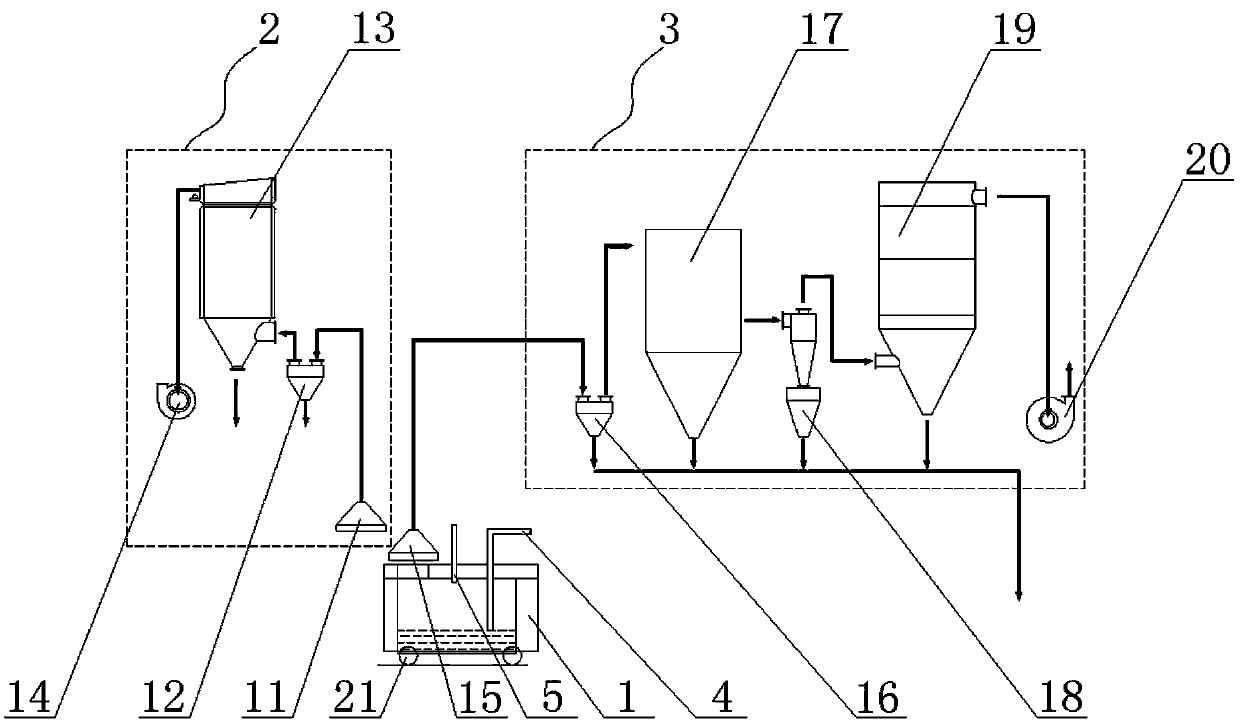

[0040]The steps are as follows: move the autothermal oxidation furnace 1 to the ambient cooling dust collection system 2, turn on the centrifugal fan 14 of the ambient cooling dust collection system 2, align the smoke exhaust port 7 with the fume hood 11, and use natural gas to heat up to 1200°C, Add the tin ingot from the feeding port 6 to start melting, observe the height of the tin liquid from the operation port 9 to 300mm, at this time the furnace temperature drops to 1000 ° C, continue to heat to the furnace temperature of 1200 ° C, stop the heating, and move the self-heating oxidation furnace 1. Go to the main process cooling and dust collection system 3, connect the main process fume hood 15 with the exhaust port 7, turn on the main process centrifugal fan 20, slowly lower the spray gun 4, insert the spray gun 4 into the autothermal oxidation furnace 1 from the spray gun hole 8, and pass through the For the primary air and fuel, insert the secondary air pipe 5 into the s...

Embodiment 2

[0043] Move the autothermal oxidation furnace 1 to the ambient cooling dust collection system 2, turn on the centrifugal fan 14 of the ambient cooling dust collection system 2, align the exhaust port 7 with the fume hood 11, and use natural gas to heat up to 1211 ° C. 6. Add the tin ingot to start melting, observe the height of the tin liquid from the operation port 9 to 320mm, at this time the furnace temperature drops to 1000 ℃, continue to heat to the furnace temperature of 1280 ℃, stop heating, and move the autothermal oxidation furnace 1 to the main process Cool the dust collection system 3, connect the main process fume hood 15 with the smoke exhaust port 7, turn on the main process centrifugal fan 20, slowly lower the spray gun 4 into the autothermal oxidation furnace 1 from the spray gun hole 8, and introduce primary air and fuel , insert the secondary air pipe 5 into the secondary air port 10 and blow the secondary air; open the primary air pipe valve and the secondary...

Embodiment 3

[0045] Move the autothermal oxidation furnace 1 to the ambient cooling dust collection system 2, turn on the centrifugal fan 14 of the ambient cooling dust collection system 2, align the exhaust port 7 with the fume hood 11, and use natural gas to heat the temperature to 1230 ° C. 6. Add the tin ingot to start melting, observe the height of the tin liquid from the operation port 9 to 280mm, at this time the furnace temperature drops to 1000 ℃, continue to heat to the furnace temperature of 1240 ℃, stop heating, and move the autothermal oxidation furnace 1 to the main process Cool the dust collection system 3, connect the main process fume hood 15 with the smoke exhaust port 7, turn on the main process centrifugal fan 20, slowly lower the spray gun 4 into the autothermal oxidation furnace 1 from the spray gun hole 8, and introduce primary air and fuel , insert the secondary air pipe 5 into the secondary air port 10 and blow the secondary air; open the primary air pipe valve and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com