Colorless and transparent polyimide resin material and preparation method thereof

A polyimide resin, transparent technology, applied in the field of colorless and transparent polyimide resin material and its preparation, can solve the limitation of large-scale application of polyimide film, cannot be applied on a large scale, hexafluoropropane di Anhydride is expensive and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

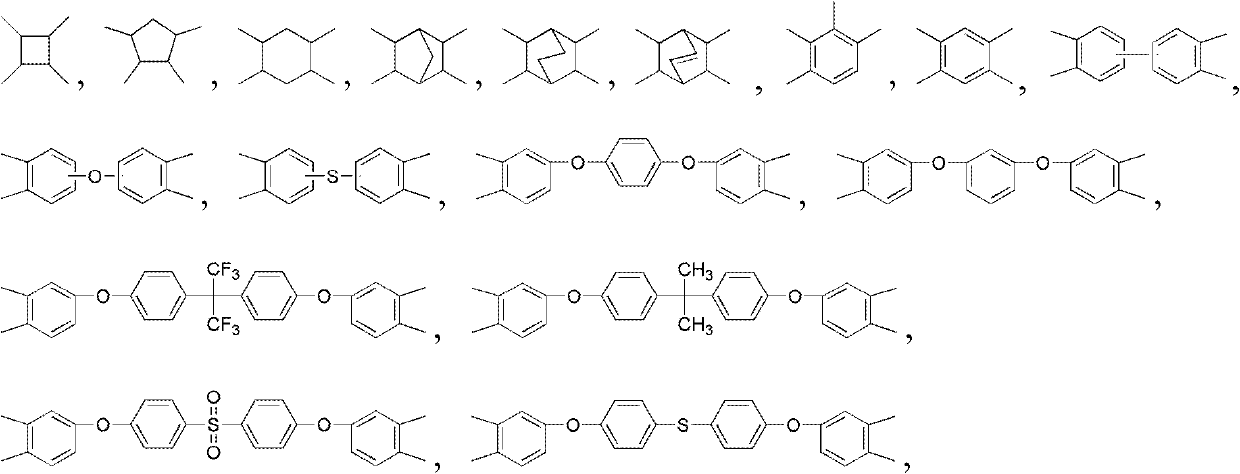

Method used

Image

Examples

Embodiment 1

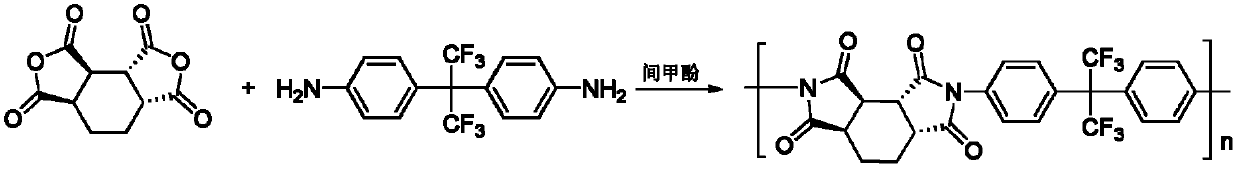

[0055] In this embodiment, the colorless and transparent polyimide resin material has the following structural formula:

[0056]

[0057] The specific preparation method is: at room temperature, 16.0 grams (0.05 moles) of 2,2'-bis(trifluoromethyl)diaminobiphenyl and 200 milliliters of m-cresol are added to a reaction reaction that is equipped with a stirrer and nitrogen protection device. After treating that 2,2'-bis(trifluoromethyl)diaminobiphenyl is completely dissolved, add 5.6 grams (0.025 moles) of cis-1,2,3,4-cyclohexane tetraacid dianhydride and 5.6 grams (0.025 moles) of trans-1,2,3,4-cyclohexanetetraacid dianhydride, continue stirring until the two are completely dissolved. Then the temperature was raised to 180°C for 5h. During the reaction process, the water generated by the reaction is removed from the reaction system by a water removal device to obtain a polyimide solution. Drop the reaction solution into ethanol to obtain fibrous polyimide precipitates, and...

Embodiment 2

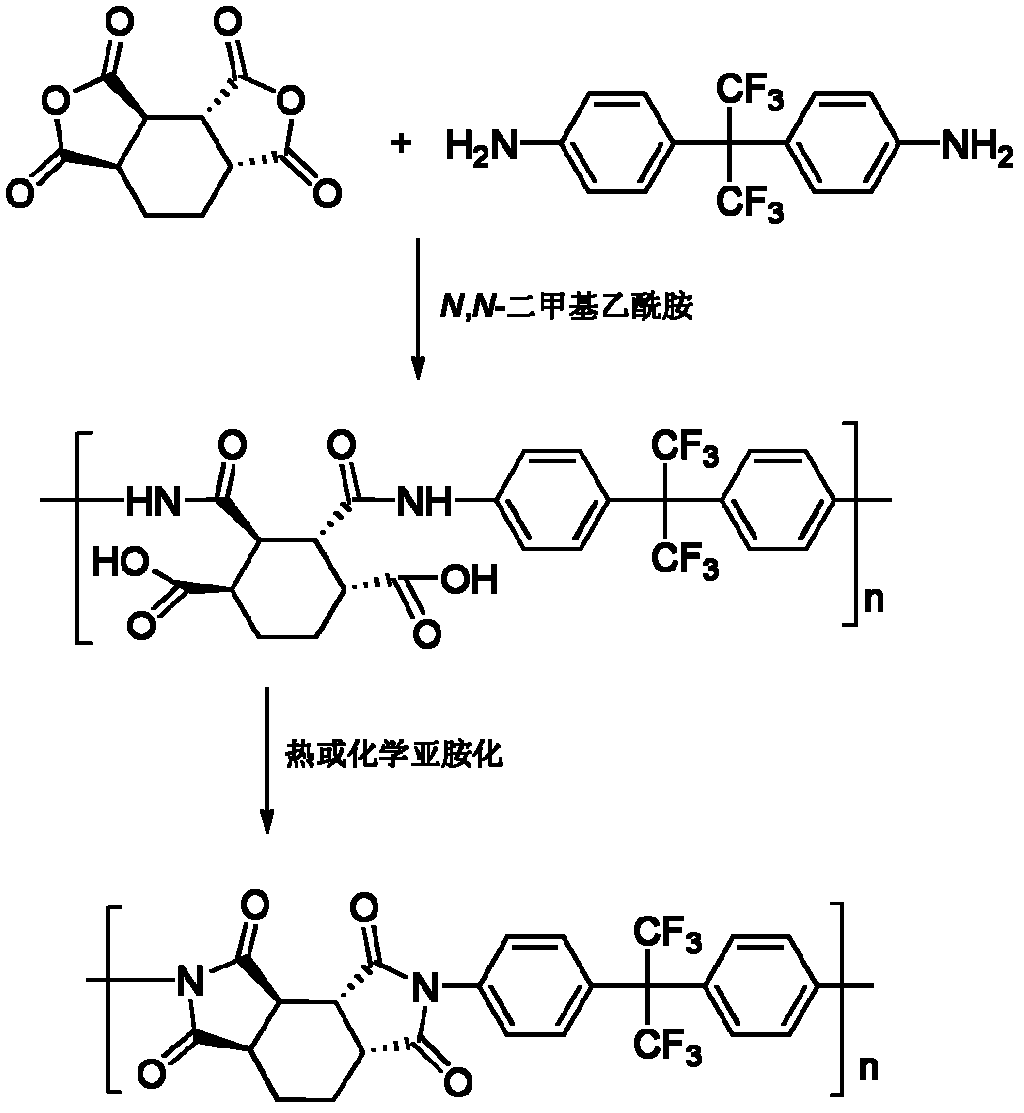

[0069] In this embodiment, the colorless and transparent polyimide resin material has the following structural formula:

[0070]

[0071] The specific preparation method is: at room temperature, 16.7 grams (0.05 moles) of 2,2-bis(4-aminophenyl)hexafluoropropane and 160 milliliters of N,N-dimethylformamide are added to a mixer equipped with in the reactor. After 2,2'-bis(4-aminophenyl)hexafluoropropane is completely dissolved, add 11.2 grams (0.05 mole) of cis-1,2,3,4-cyclohexane tetraacid dianhydride at room temperature . After the system was completely dissolved, the temperature was raised to 50° C. and stirred continuously for 3 hours to obtain a viscous polyamic acid solution.

[0072]Coat the polyamic acid solution on a clean glass plate, place the glass plate in a drying oven with nitrogen protection, and heat up according to the following procedures: 80°C, 4h; 150°C, 1h; 200°C, 1h; 250°C, 1h; 300°C, 0.5h. After the temperature dropped to room temperature, the glas...

Embodiment 3

[0075] In this embodiment, the colorless and transparent polyimide resin material has the following structural formula:

[0076]

[0077] The specific preparation method is as follows: at room temperature, 16.7 g (0.05 mol) of 2,2-bis(4-aminophenyl) hexafluoropropane and 100 ml of N-methylpyrrolidone are added into a reactor equipped with a stirrer. After 2,2'-bis(4-aminophenyl)hexafluoropropane is completely dissolved, add 11.2 grams (0.05 moles) of trans-1,2,3,4-cyclohexanetetraacid dianhydride at room temperature and 50 ml o-dichlorobenzene. Continue stirring until the two are completely dissolved. Then the temperature was raised to 180°C for 10 h. During the reaction process, the water generated by the reaction is removed from the reaction system by a water removal device to obtain a polyimide solution. Drop the reaction solution into ethanol to obtain fibrous polyimide precipitates, and dry to obtain polyimide powder. The glass transition temperature of the polymer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com