Preparation method for methyl phenyl vinyl polysiloxane for packaging LED

A methyl phenyl ethylene and LED packaging technology, applied in the field of silicone preparation, can solve the problems of large difference in refractive index, complex product composition, low product light transmittance, etc., to improve light transmittance and optimize polymerization time. , the effect of high refractive index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

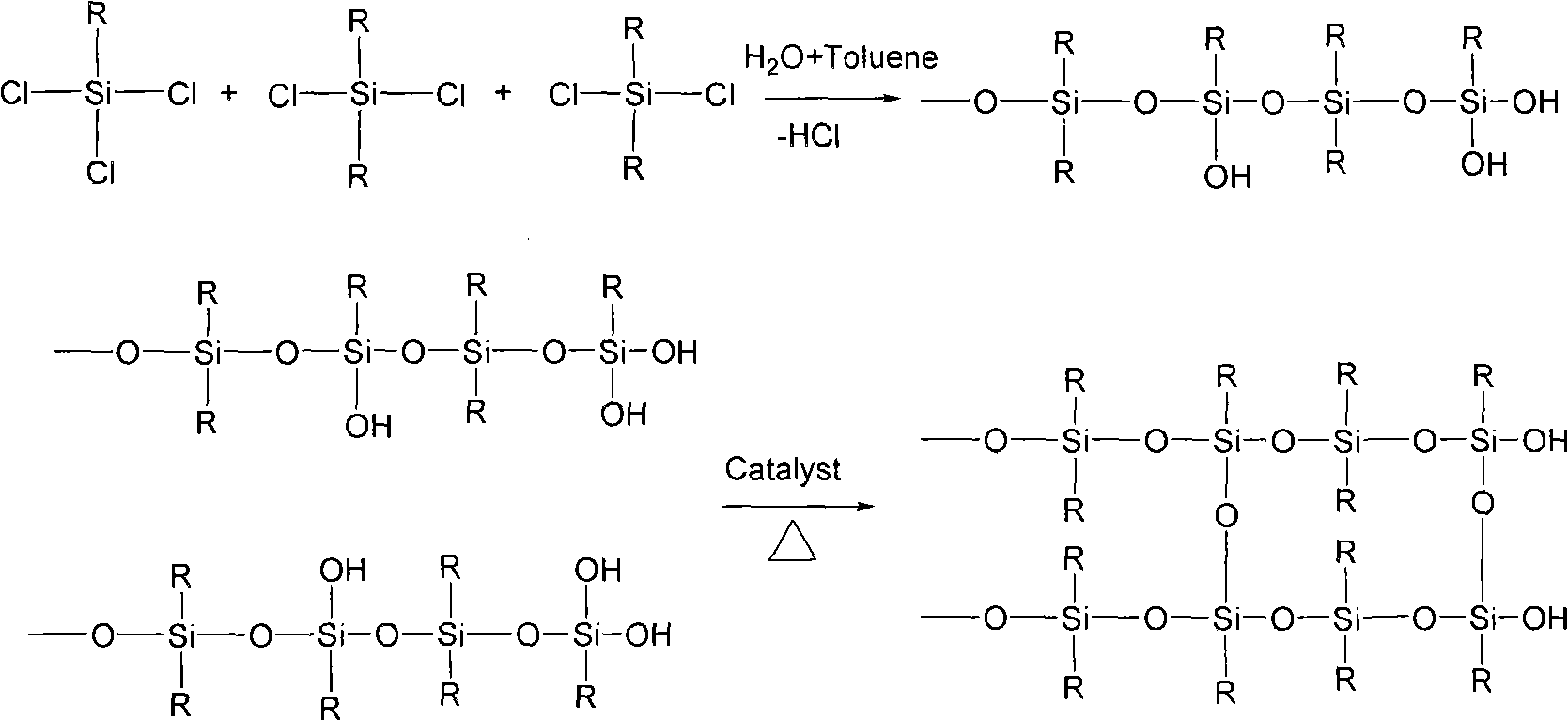

Method used

Image

Examples

Embodiment 1

[0032] Into a 1L three-neck flask filled with 46ml of toluene and 360ml of water, under stirring at 45°C, 50ml of PhSiCl 3 , 39.2mlMeViSiCl 2 , 45.1ml Me 2 SiCl 2 , 95ml of toluene was added dropwise for about 1 hour, and the stirring was continued for 1 hour. Stand still, separate layers, and remove the acid solution in the lower layer with a separatory funnel. Use deionized water at 40°C~50°C to neutral. Take 50g of the obtained silanol toluene solution, add 50g toluene and 0.05g KOH, reflux in a 250ml three-necked flask at 70~80°C for 5h, cool, add 1.5g MeSiCl 3 , stirred for 1 h, washed with deionized water until neutral. Concentrate at 0.8MPa~0.96MPa, and remove the remaining toluene and the water generated by the polycondensation reaction to obtain a clear and transparent methylphenyl vinyl silicone resin with a vinyl mole percentage of 0.304, R / Si=1.38, and a refractive index Rate 1.490.

Embodiment 2

[0034] To a 1L three-neck flask filled with 46ml of toluene and 360ml of water, add 50ml of PhSiCl dropwise within 2h under stirring at 40°C 3 , 22ml MeViSiCl 2 , 26ml Me 2 SiCl 2 , 35ml MePhSiCl 2 , 88ml of toluene mixed solution, continue to stir for 1h. Stand still, separate layers, and remove the acid solution in the lower layer with a separatory funnel. Wash with deionized water at 40°C~50°C for 7-8 times until neutral, and add 50g of silanol toluene solution to 50g of toluene and 0.05gKOH, reflux in a 250ml three-necked flask at 70~80°C for 2h, cool, Add 1.5g MeSiCl 3 , stirred for 1 h, washed with deionized water until neutral. Concentrate at 0.8MPa~0.96MPa, and remove the remaining toluene and the water generated by the polycondensation reaction to obtain a clear and transparent methylphenyl vinyl silicone resin with a vinyl mole percentage of 0.185, R / Si=1.47, and a refractive index Rate n D 25 = 1.5465.

Embodiment 3

[0036] To a 1L three-neck flask containing 46ml of toluene and 360ml of water, add 50ml of PhSiCl dropwise within 2h under stirring at 50°C 3 , 22ml MeViSiCl 2 , 13ml Me 2 SiCl 2 , 17.5ml MePhSiCl 2 , 88ml of toluene mixed solution, continue to stir for 1h. Stand still, separate layers, and remove the acid solution in the lower layer with a separatory funnel. Wash 7-8 times with deionized water at 40°C~50°C until neutral, add 50g of silanol toluene solution to 50g of toluene, 0.15g KOH, reflux in a 250ml three-necked flask at 70~80°C for 2h, cool , add 4.5g MeSiCl 3 , stirred for 1 h, washed with deionized water until neutral. Concentrate at 0.8MPa~0.96MPa, remove the remaining toluene and water generated by polycondensation reaction, and obtain a product containing part of white filaments. After decolorization by activated carbon and filtration, it is a colorless transparent methylphenyl vinyl silicone resin. The molar percentage of its vinyl group is 0.242, R / Si=1.31,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com