Bisphthalonitrile resin/aromatic amine organic montmorillonite nano composite material and preparation method thereof

A technology of phthalonitrile resin and nanocomposite material, which is applied in the field of thermosetting resin composite material to achieve the effects of good heat resistance, convenient operation and good dynamic thermomechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

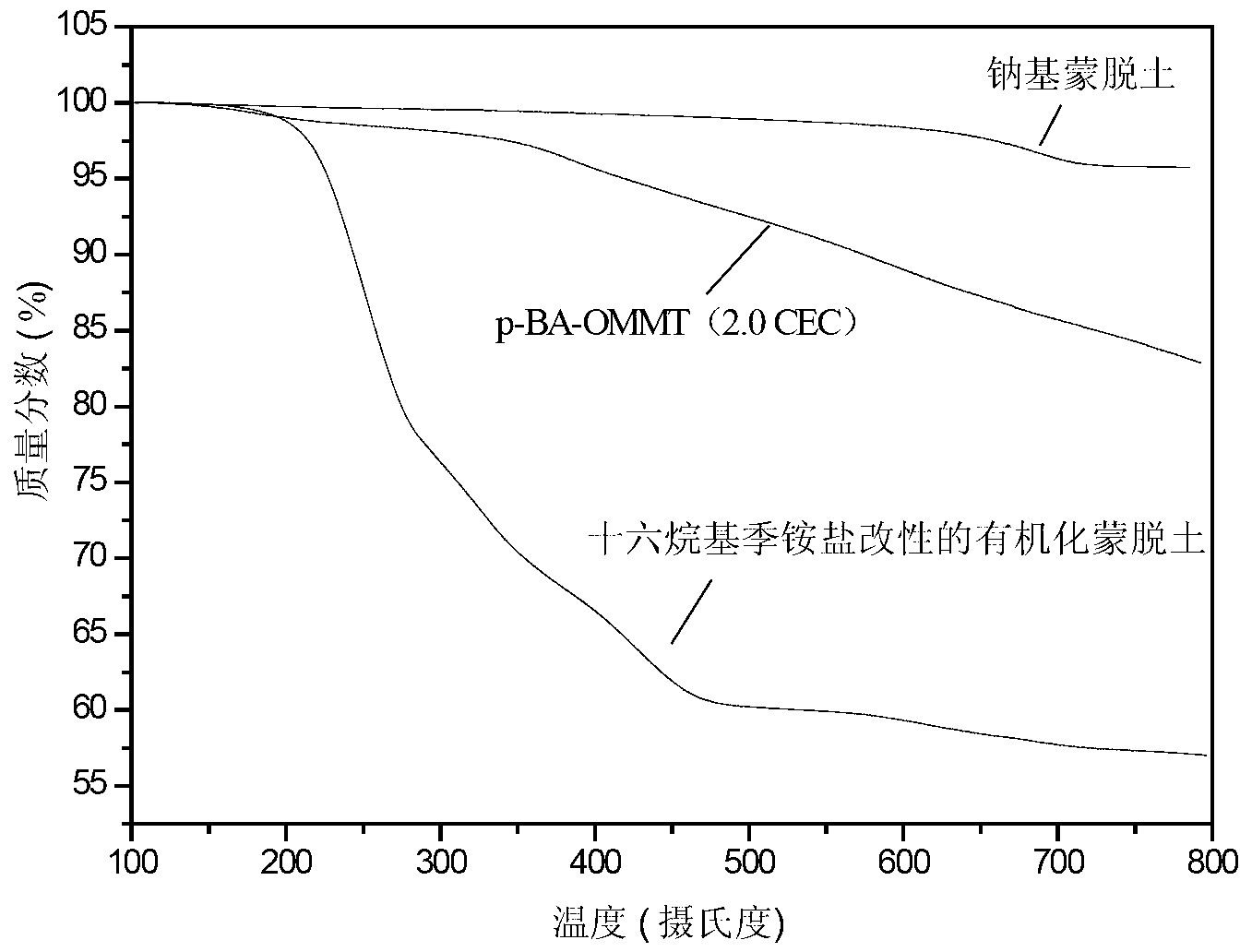

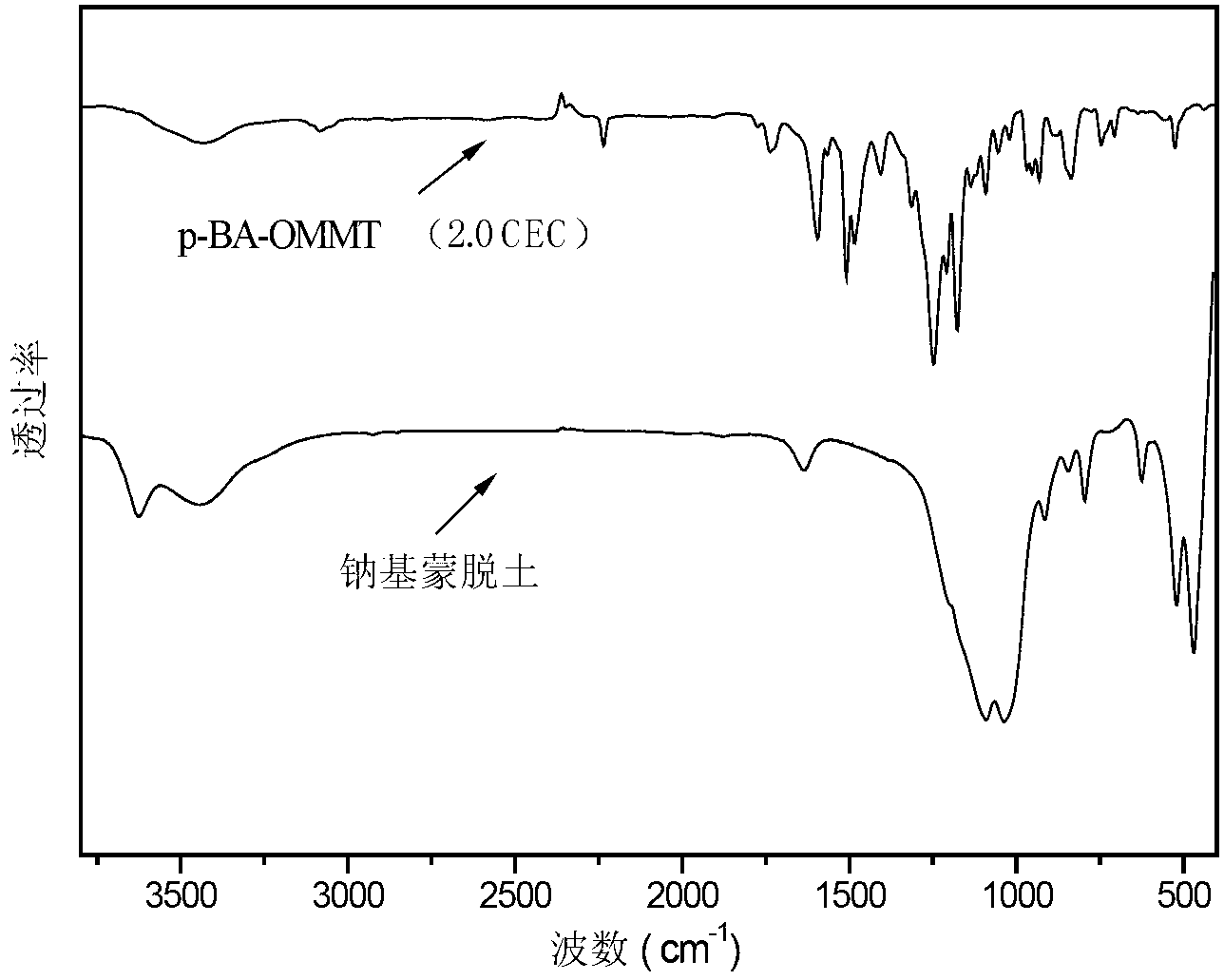

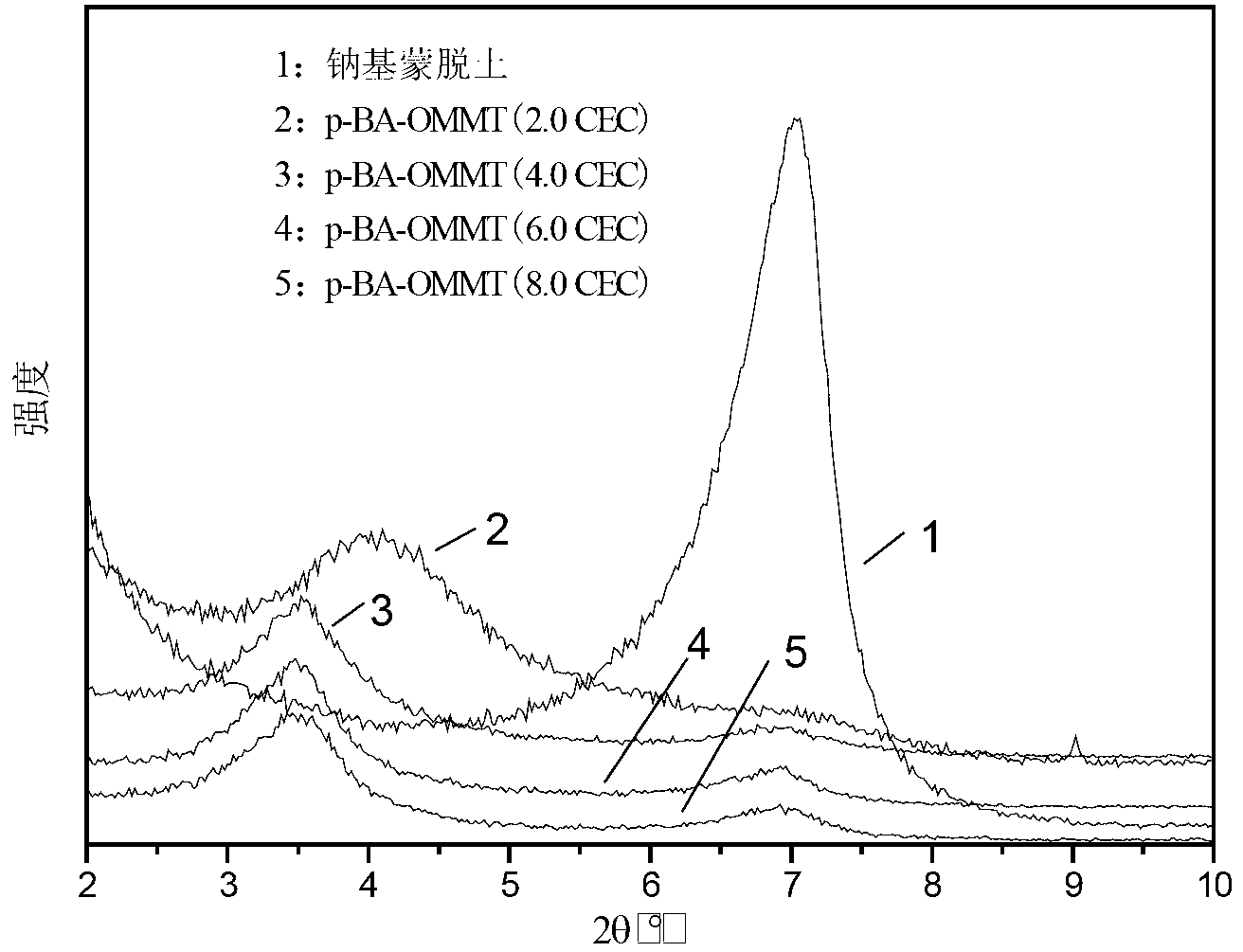

[0044] Add 1 g of refined sodium-based montmorillonite to 20 mL of distilled water, and stir for 1 h to form a stable suspension; mix 0.4327 g of p-BAPS with 30 mL of distilled water, and add concentrated hydrochloric acid dropwise to the mixture under stirring until the mixture is clear. The modifier aqueous solution is obtained; then the modifier aqueous solution is added to the sodium-based montmorillonite suspension, and stirred at a constant temperature of 75-82°C for 2 hours; after the reaction, the solid is separated and washed with distilled water several times to remove excess modifier , vacuum-dried at 80°C for 48 hours, and then ground into powder to obtain p-BA-OMMT (modifier with 2 times the total amount of cation exchange, abbreviated as 2.0CEC, the same below), the interlayer distance is 2.19nm, The temperature-programmed thermogravimetric analysis (TGA) curve is shown in the appendix figure 1 , see the attached infrared curve figure 2 , the X-ray diffraction ...

Embodiment 2

[0046] Change the amount of p-BAPS for organic modification, wherein the mass of p-BAPS is 0.8654g (4.0CEC), the synthesis process is the same as that of Example 1, the interlayer distance is 2.48nm, and the XRD curve is shown in the attached image 3 .

Embodiment 3

[0048] Change the amount of p-BAPS for organic modification, wherein the mass of p-BAPS is 1.2981g (6.0CEC), the synthesis process is the same as that of Example 1, the interlayer distance is 2.54nm, and the XRD curve is shown in the attached image 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com