Single-component reactive thixotropic polyurethane waterproof paint and preparation method thereof

A polyurethane waterproof, one-component technology, applied in the field of architectural waterproof coatings, can solve the problems of time-consuming and labor-intensive, poor constructability, large polyurethane waterproof coatings, etc., and achieve the effect of solving particularly serious flow and good constructability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

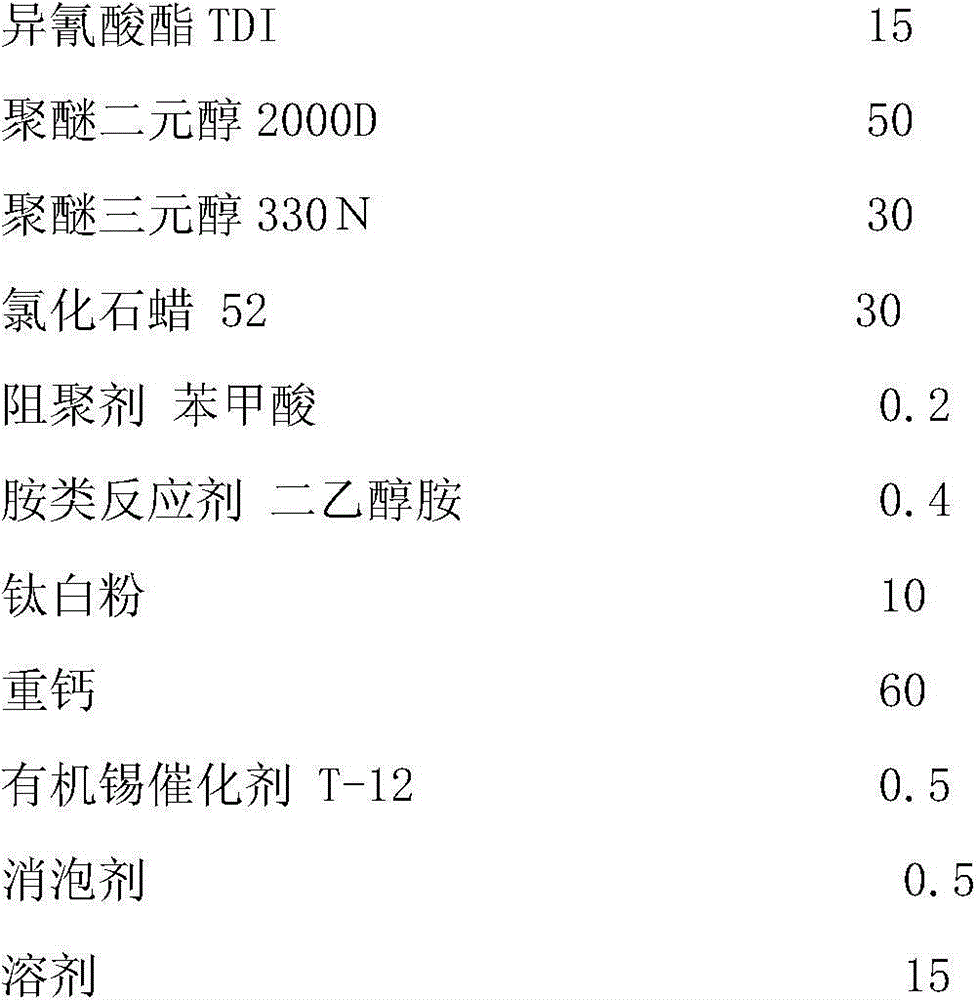

[0027] Raw material ratio:

[0028]

[0029] crafting process:

[0030] a. Add 60-100 parts by weight of polyether polyol, 20-40 parts by weight of plasticizer, and 20-80 parts by weight of pigments and fillers into the reaction vessel, stir and raise the temperature to 100°C-130°C, and the vacuum is -0.01 Dehydration under the condition of MPa for 2 to 3 hours;

[0031] b. Lower the temperature below 60°C-80°C, add 10-25 parts by weight of isocyanate, and react for 2-3 hours under stirring at 60-100°C;

[0032] c. Lower the temperature to 50°C-60°C, add 0.1-1 parts by weight of a polymerization inhibitor and 0.1-1 parts by weight of an amine reactant, and react for 2 to 3 hours under stirring at 55-65°C;

[0033] d. Lower the temperature to below 50°C-60°C, add 0.2-1 parts by weight of catalyst and 0.1-1 parts by weight of high-performance additives, stir for 1-2 hours, after the dispersion is uniform, lower the temperature to below 30°C-40°C to fully Nitrogen protectio...

Embodiment 2

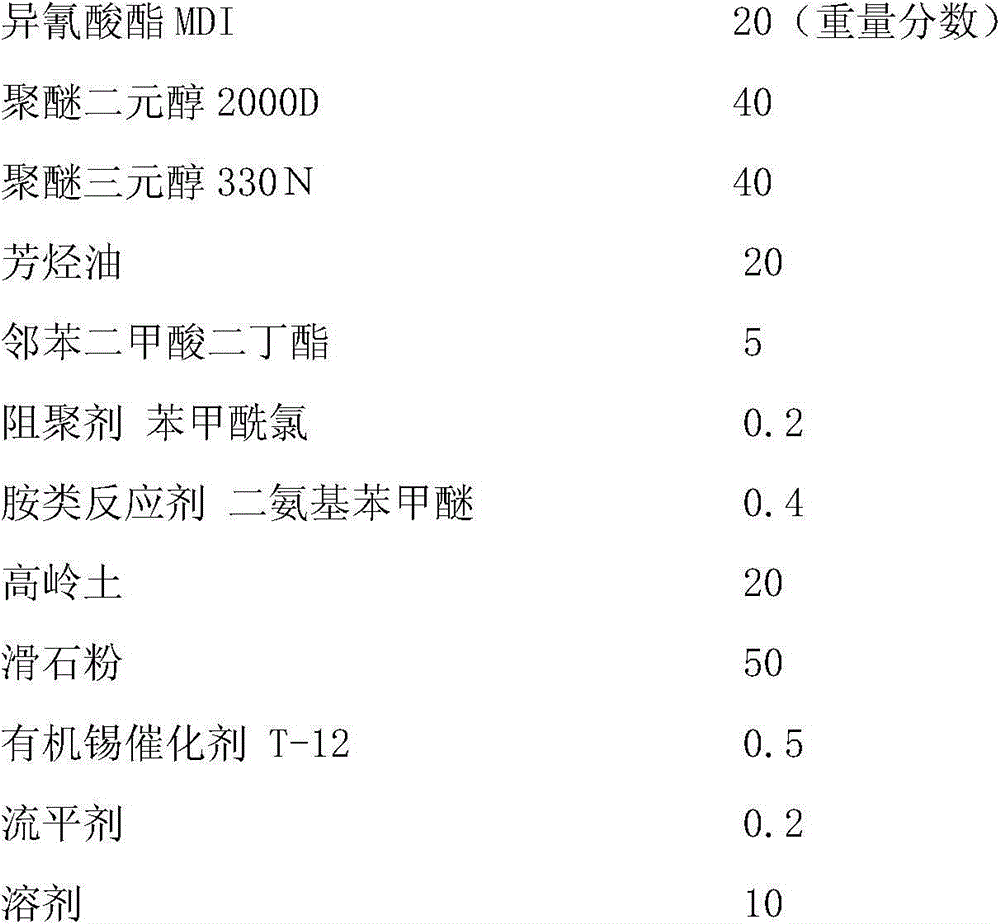

[0035] Raw material ratio:

[0036]

[0037] Technological process is identical with embodiment 1.

Embodiment 3

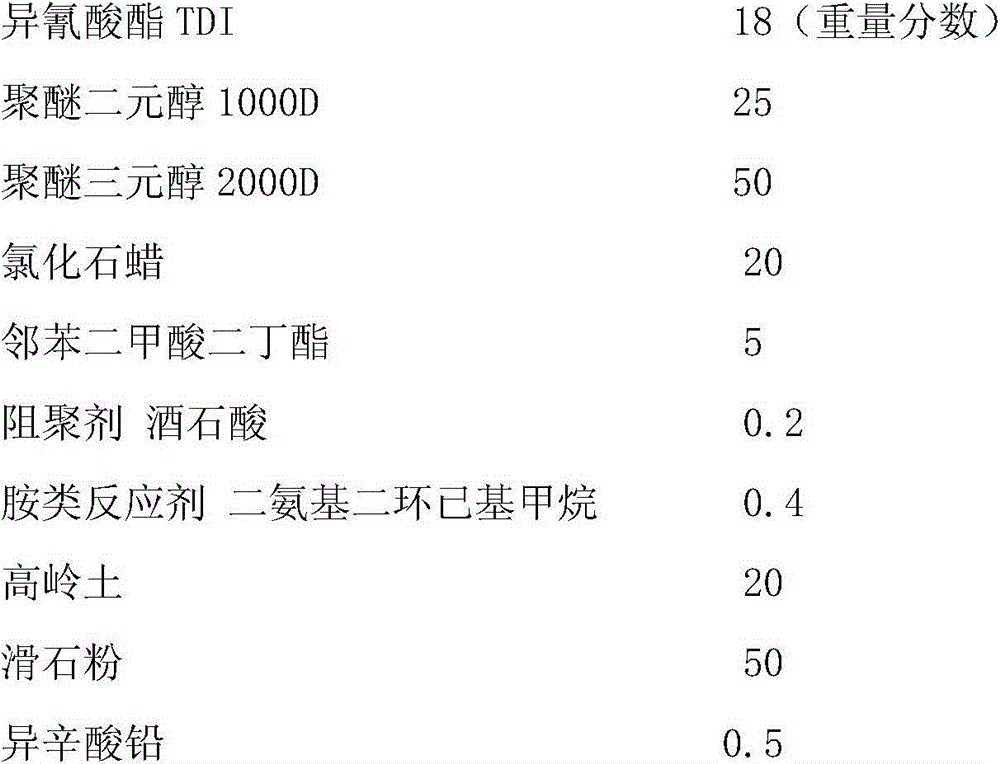

[0039] Raw material ratio:

[0040]

[0041]

[0042] Technological process is identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com