Preparation method of modified graphene oxide/PMMA composite material

A technology of composite materials and stone oxide, which is applied in the field of preparation of modified graphene oxide/PMMA composite materials, can solve the problems of incomplete exfoliation and poor dispersion of graphene oxide, and achieve increased resistivity, improved dispersion, and improved dispersion sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Graphene oxide was prepared by improving the Hummers method: 1 g of graphite powder, 0.5 g of sodium nitrate, and 23 ml of concentrated sulfuric acid were stirred in an ice bath for 30 min, and 3 g of potassium permanganate was slowly added in batches within 1 h for low-temperature reaction. After the end, heat up to 35°C for medium-temperature reaction. After the end, add 50ml of distilled water, quickly raise the temperature to 95°C and enter the high-temperature reaction for 0.5 hours, stop heating, add 100ml of distilled water and 10ml of hydrogen peroxide in batches, let stand and centrifuge, and prepare a mass fraction of 5%. Hydrochloric acid solution, distilled water wash and freeze-dry 24h to obtain graphene oxide;

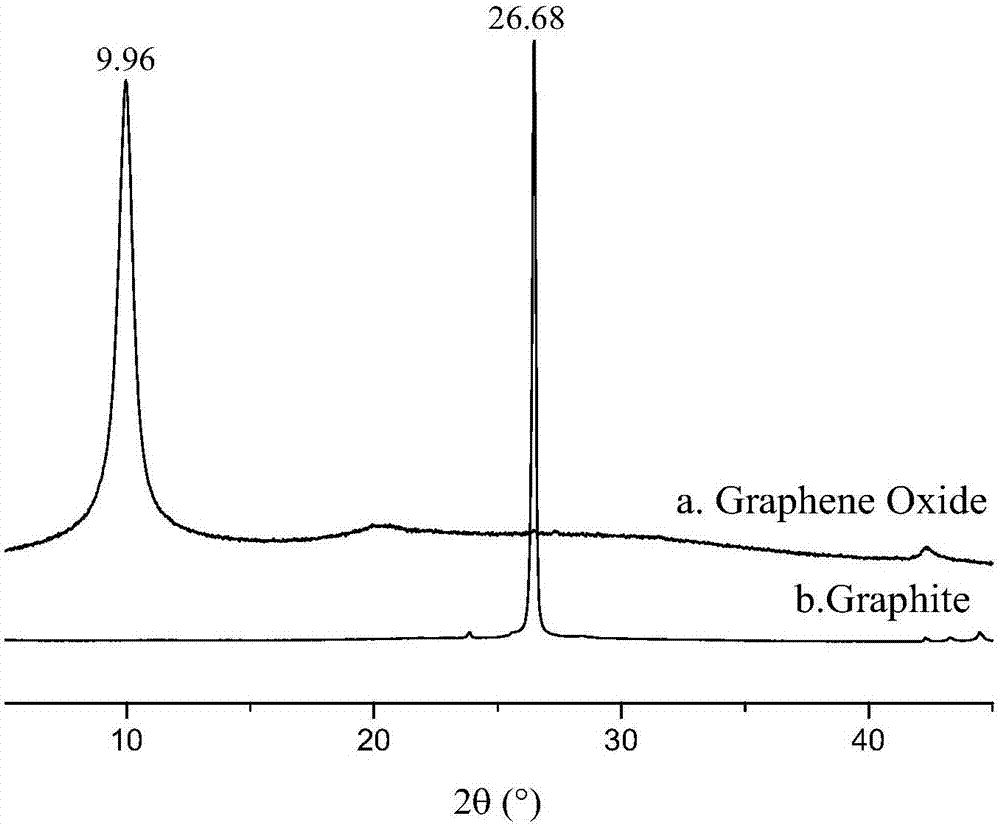

[0024] Experiments have proved that the graphene oxide prepared by the above improved Hummers method has a high degree of oxidation and good dispersion in water. figure 1 It can be seen that compared with graphite powder, graphene oxide has a w...

Embodiment 2

[0031](1) improve Hummers method to prepare graphene oxide method with embodiment 1;

[0032] (2) the preparation of aminated graphene oxide is the same as in Example 1;

[0033] (3) Preparation of modified graphene oxide surface grafted with polymethyl methacrylate: take 0.035g of GO-ODA obtained in step (2), ultrasonically disperse it in 5.0ml monomer MMA, and then add 0.35 g BPO in toluene, in N 2 React at 60°C for 5 hours under protection, centrifuge, wash, dry and disperse in THF;

[0034] (4) Take by weighing 7.0g PMMA pellets and be dissolved in THF, the graphene oxide surface grafting polymethyl methacrylate 0.035g obtained in (3) is dispersed in THF to obtain mixed solution, add the THF that is dissolved in PMMA dropwise In the solution, the PMMA composite material was obtained by casting film on a polytetrafluoroethylene plate.

Embodiment 3

[0036] (1) improve Hummers method to prepare graphene oxide method with embodiment 1;

[0037] (2) the preparation of aminated graphene oxide is the same as in Example 1;

[0038] (3) Preparation of modified graphene oxide surface grafted with polymethyl methacrylate: take 0.035g of GO-ODA obtained in step (2), ultrasonically disperse it in 5.0ml monomer MMA, and then add 0.70 g BPO in toluene, in N 2 React at 60°C for 5 hours under protection, centrifuge, wash, dry and disperse in THF;

[0039] (4) Take by weighing 7.0g PMMA pellets and be dissolved in THF, the graphene oxide surface grafting polymethyl methacrylate 0.035g obtained in (3) is dispersed in THF to obtain mixed solution, add the THF that is dissolved in PMMA dropwise In the solution, the PMMA composite material was obtained by casting film on a polytetrafluoroethylene plate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com