Polyimide fiber and its preparing method

A technology of polyimide fiber and polyimide, which is applied in the field of polymer fiber and its preparation, can solve the problems that the mechanical properties need to be improved, and achieve the effect of prolonging the solidification time, optimizing the solidification conditions and ideal mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

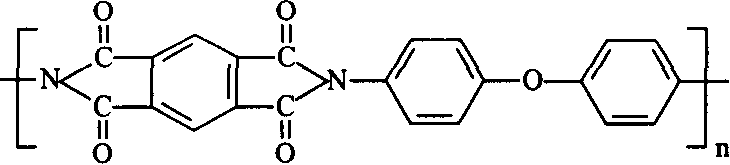

Image

Examples

Embodiment 1

[0014] The synthesis reaction of polyamic acid is carried out in a three-necked flask, which is stirred by a stirrer with a multi-stage speed governor, and nitrogen gas is passed through one side of the three-necked flask to keep the reactants from being oxidized. The used three-necked flask was dried in an oven at 130° C. for 3 hours before use. Accurately weigh 14.592 g of 4,4'-diaminodiphenyl ether (ODA) and 16.212 g of pyromellitic dianhydride (PMDA) with an electronic balance, first add the weighed diamine into the three-necked flask, and add the solvent DMAC ( Finally add 160mL) and make it completely dissolve into a transparent liquid under stirring. While stirring, use the freezing bath of the low-temperature cooling liquid circulation pump to cool it to 0°C, and then add the dianhydride powder in four times while stirring, each time 1 hour apart. Then use the metered DMAc to wash the remaining dianhydride on the bottle wall into the bottle, and stir and react under n...

Embodiment 2-5

[0016] The reaction process is the same as in Example 1, and other conditions are shown in Table 1.

[0017] implement

Embodiment 6

[0019] The polyamic acid solution obtained in Example 1 was spun and shaped using the wet process route shown in Figure 2. After filling about 150mL of polyamic acid spinning solution into a special storage tank with a spinneret, inject the circulating fluid at 0°C from the low-temperature cooling liquid circulation pump into the jacket of the slurry storage tank to make the spinning solution Keep at 0°C, stand under normal pressure for defoaming for 15 hours, and then perform spinning operation. Use nitrogen to add a pressure of 0.3MPa to the slurry, and the spinning solution passes through a 1000-mesh filter cloth, and is sprayed out through the spinneret into the vertical coagulation bath. The extrusion speed of the spinning slurry is 11.90m / min, and the vertical coagulation bath The length of the wire is 0.75m. In the coagulation bath, the thread is properly solidified and enters the water bath through the godet roller. The length of the water bath is 1.85m. The speed of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com