Method for preventing heavy steel ingot from liquating by different pouring ladles

A steel ingot and segregation technology, which is applied in the field of suppressing segregation of large steel ingots through multi-clad casting, can solve problems such as segregation of large steel ingots, achieve the effects of reducing negative segregation at the bottom, improving the quality of steel ingots, and increasing the time interval

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

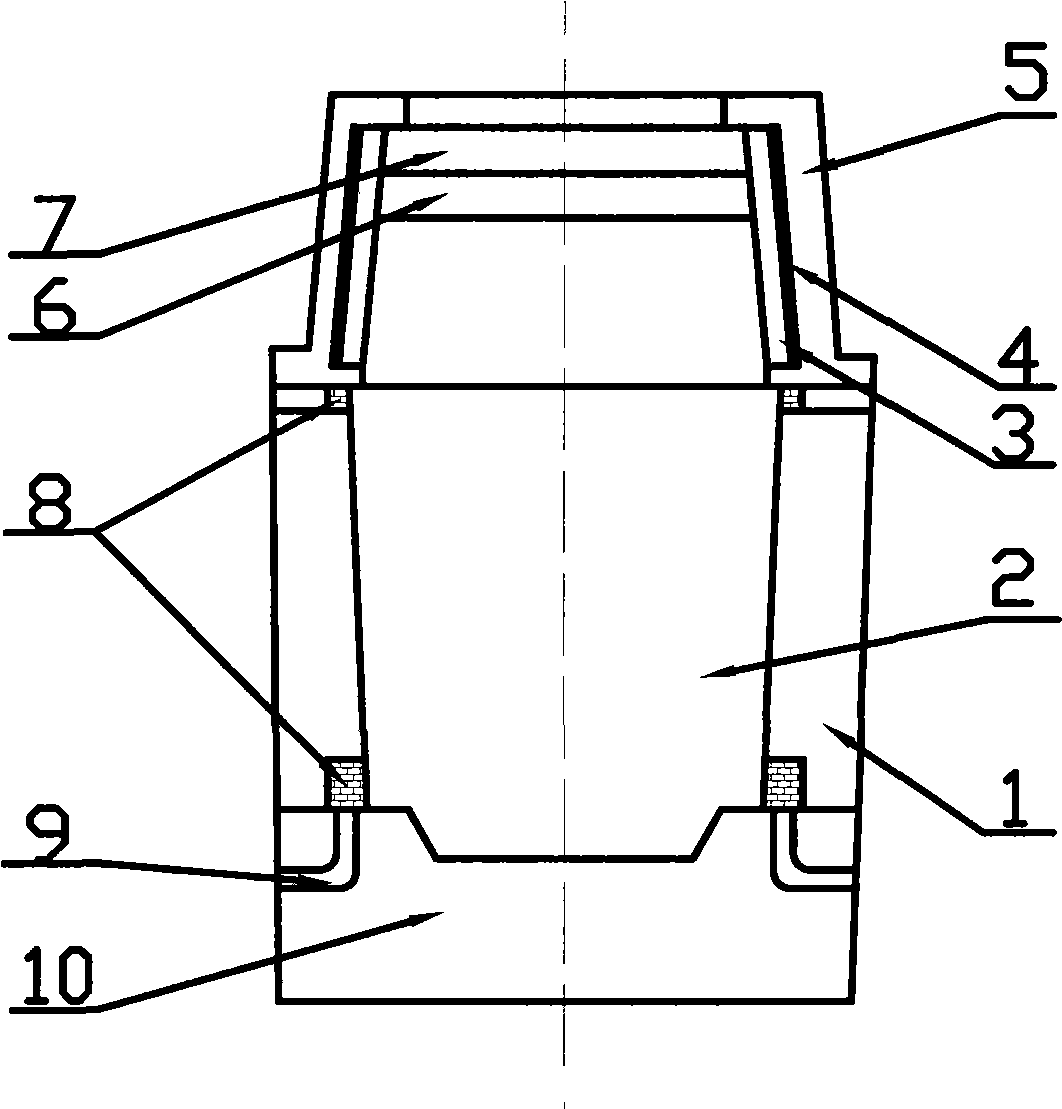

[0056] Such as figure 1 As shown, the material of the steel ingot mold is gray cast iron HT150, the preheating temperature of the steel ingot mold is 50°C, the riser adopts thermal insulation riser, the taper of the riser is 11.5%, the ratio of height to diameter of the steel ingot is 1.15:1; the weight of pouring molten metal is 500 tons , superheating temperature is 20℃, by weight percentage, 508-3 low alloy steel chemical composition: C: 0.18%, Si: 0.20%, Mn: 1.45%, Mo: 0.5%, Ni: 0.75%, Cr: 0.15% , P≤0.005%, S≤0.002%, Fe balance. The top of the riser is filled with heating agent and thermal insulation covering agent.

[0057] Process 1: (1) Top pouring is used, and vacuum is drawn before pouring to reduce secondary oxidation. (2) Simultaneously use thermal insulation riser, heating agent and thermal insulation covering agent to minimize the shrinkage cavity and loose defects of steel ingots. (3) The first bag pouring contains molten steel containing 0.21wt% C, the second...

Embodiment 2

[0063] The difference from Example 1 is: the material of the steel ingot mold is gray cast iron HT250, the preheating temperature of the steel ingot mold is 150° C., the riser adopts a thermal insulation riser, and the taper of the riser is 10%; the weight of pouring molten metal is 600 tons.

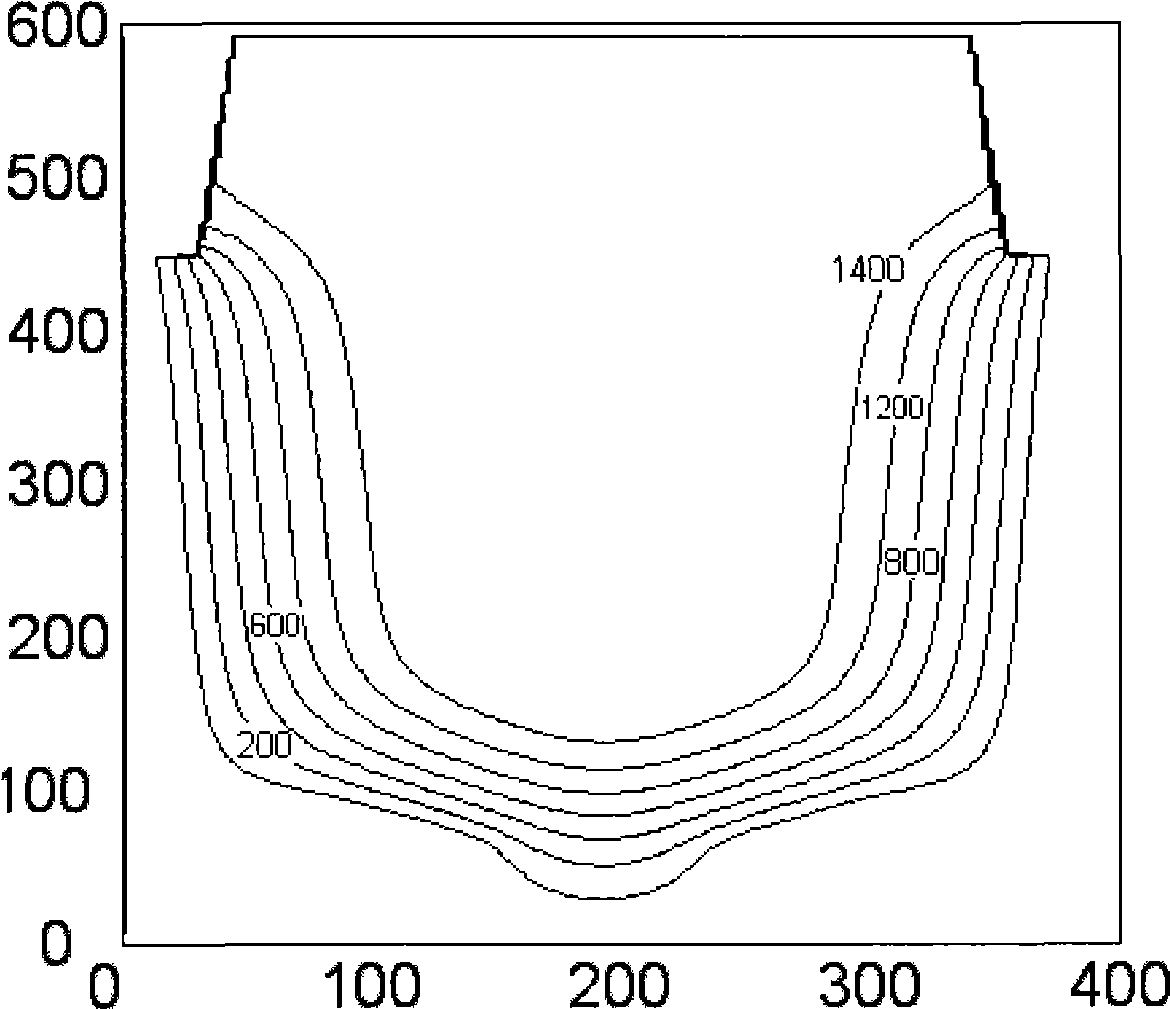

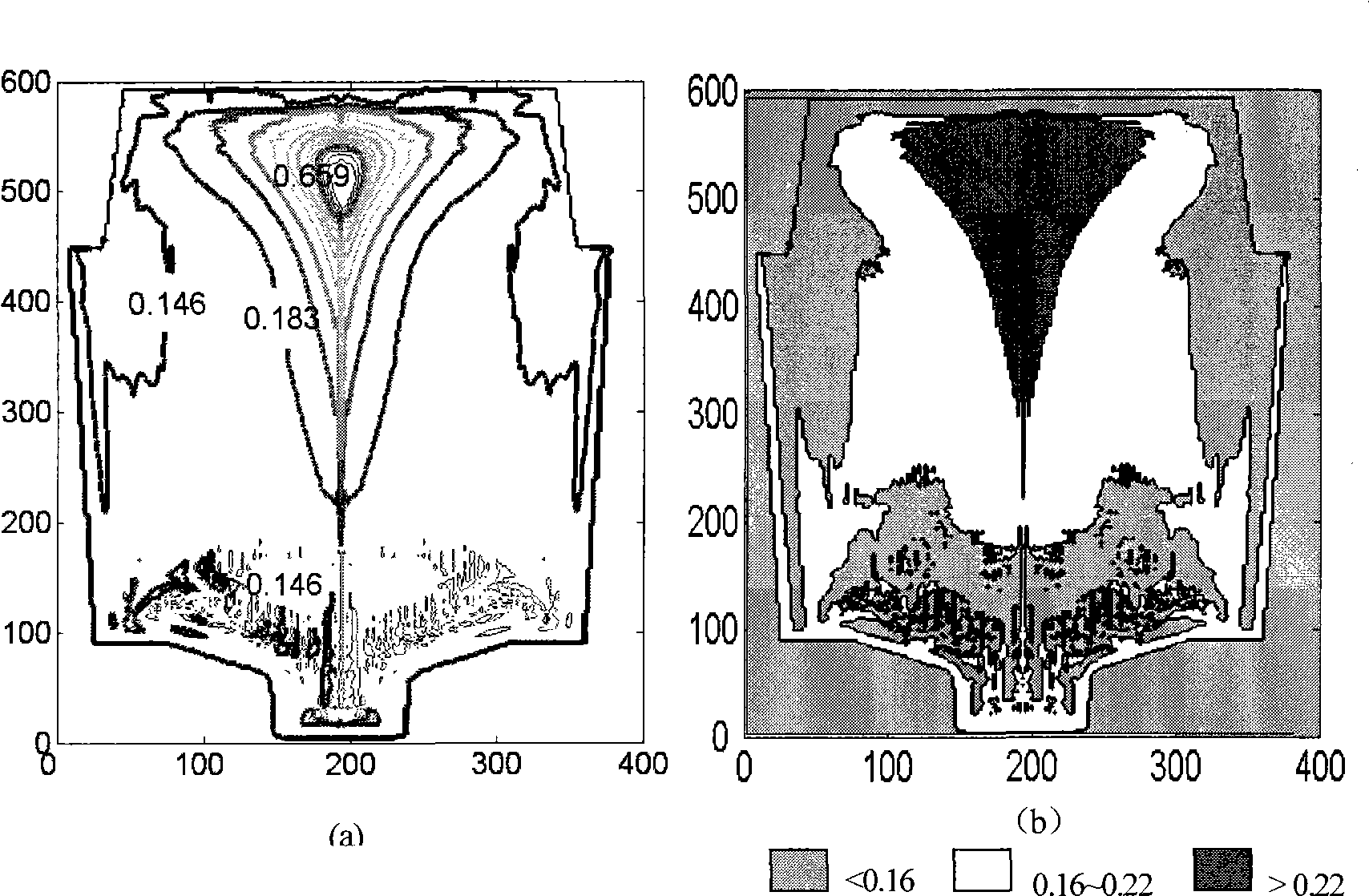

[0064] The present invention adopts computer simulation software to carry out the simulation of macroscopic segregation, Figure 9 Corresponding process one, Figure 10 Corresponding process two, Figure 11 Corresponding process three, Figure 12 Corresponding process four, Figure 13 Corresponding to process five, Figure 14 Corresponding to process six, Figure 15 Corresponding process seven.

[0065] Process 4: (1) Using top pouring, vacuuming before pouring to reduce secondary oxidation. (2) Simultaneously use thermal insulation riser, heating agent and thermal insulation covering agent to minimize the shrinkage cavity and loose defects of steel ingots. (3) The first bag pour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com