Preparation method of precious metal alloy/carbon material supported catalyst

A supported catalyst and carbon material technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc. Large size, slow drying speed and other problems, to achieve the effect of small size, high production efficiency and uniform composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Pt 3 Preparation of Co / Conductive Carbon Black Supported Catalyst

[0028] Step 1, get 1 gram of chloroplatinic acid hexahydrate [H 2 PtCl 6 ·6H 2 O], 0.187 grams of cobalt nitrate hexahydrate [Co(NO 3 ) 2 ·6H 2 O] Dissolve in 150mL deionized water by ultrasonication for 10min, then add 1.66g of Vulcan XC-72R carbon black and 1.66g of PVP (average molecular weight 8000) and mix well by ultrasonication for 20 minutes. The molar ratio of platinum to cobalt atoms is 3:1, and the weight ratio of platinum plus cobalt to conductive carbon black is 1:4.

[0029] Step 2, the mixed mixed solution is sprayed and quickly dried to obtain a dry mixed powder: the fine mist is sprayed onto a quartz plate with a temperature of 270 ° C, and the aqueous solution is quickly evaporated to obtain a dry mixed powder, and the spray speed is 20 ml solution / min.

[0030] Step 3, remove the dry mixed powder obtained in step 2 from the quartz plate, and anneal in hydrogen for 60 minutes a...

Embodiment 2

[0033] Pt 3 Preparation of Co / Conductive Carbon Black Supported Catalyst

[0034] This example is a modification example of Example 1. Other implementation conditions are the same as in Example 1, except that the annealing temperature in hydrogen in step 3 is 700°C.

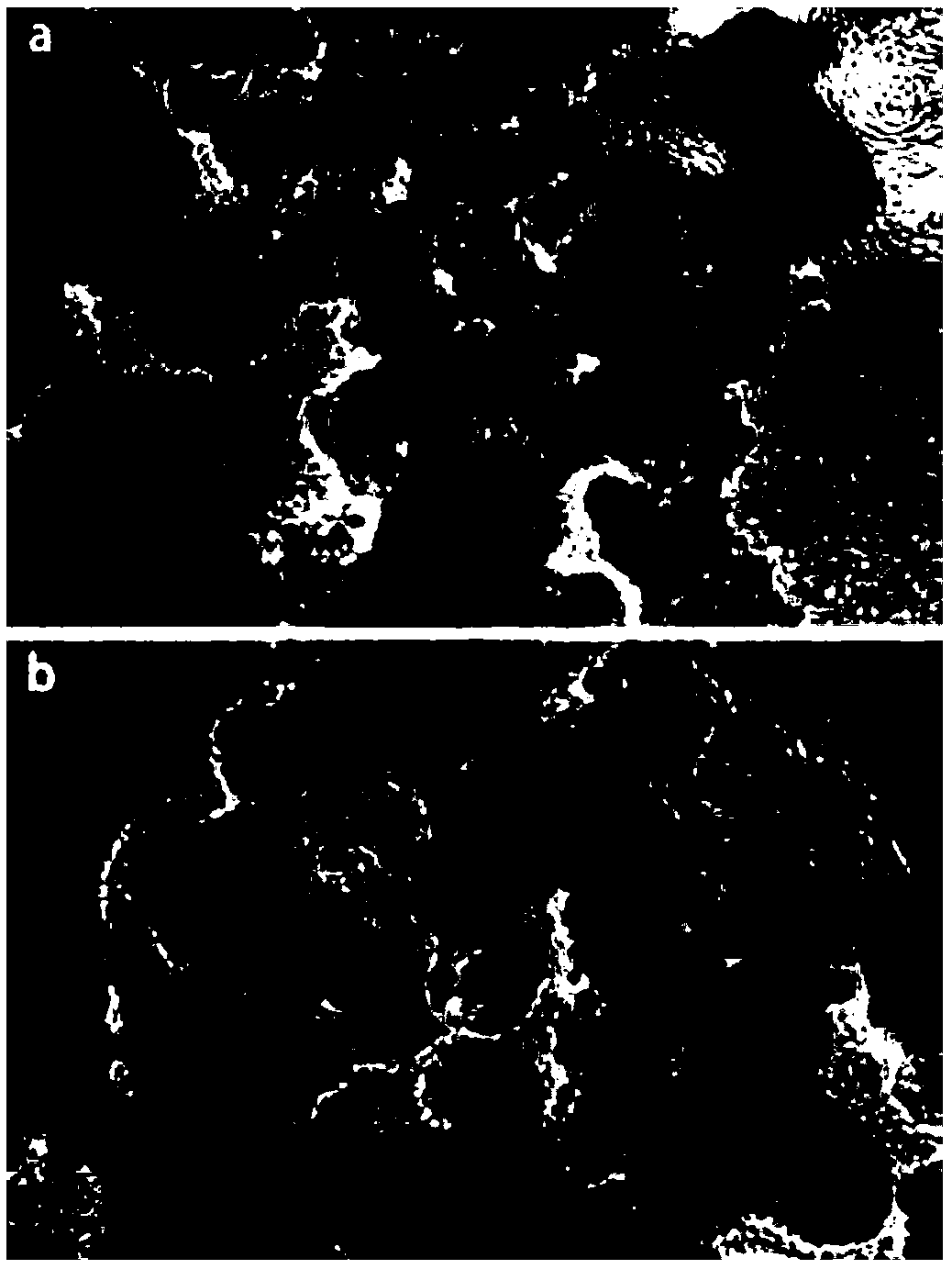

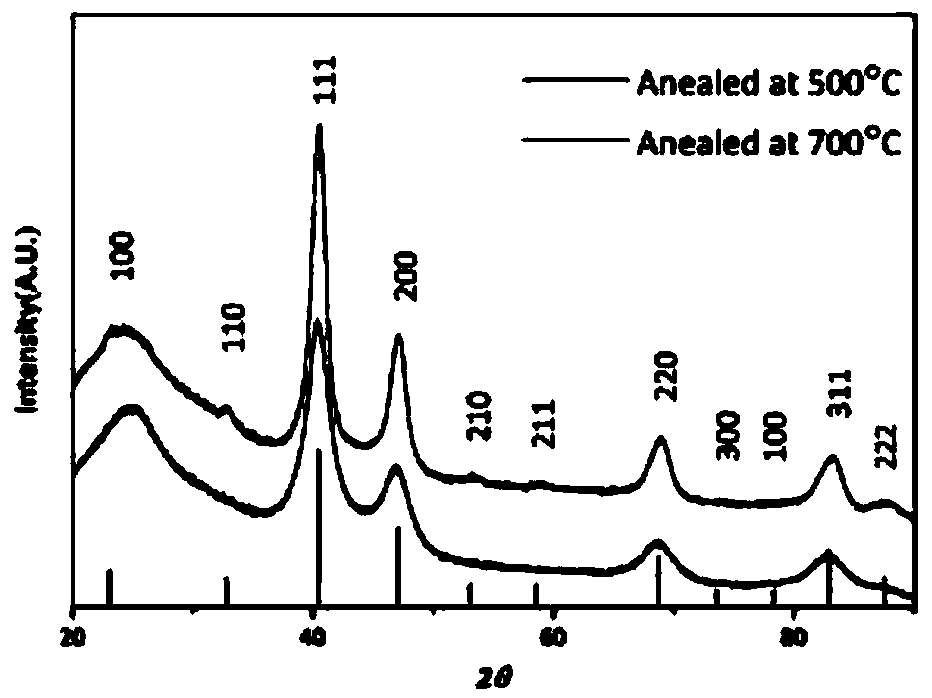

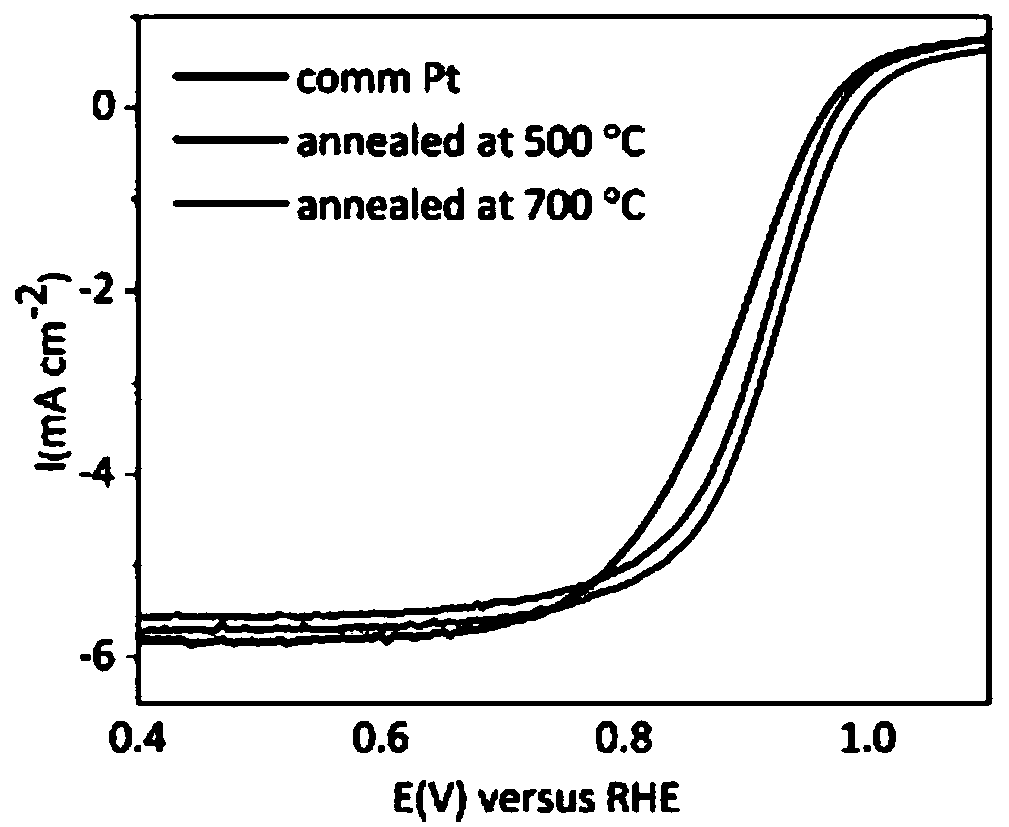

[0035] Effect: Pt prepared in Example 2 3 TEM photo of Co / conductor carbon black as figure 1 Shown, Pt 3 The average size of Co alloy nanoparticles is about 5.1 nm. The XRD results after hydrogen reduction at 700°C are as follows figure 2 Shown, Pt 3 The crystal structure of Co nanoparticles is L 10 Quartet orderly structure. To test Pt 3 Oxygen reduction catalytic activity of Co / conductive carbon black, which will be prepared to obtain Pt 3 Co / conductive carbon black, test oxygen reduction performance in 0.1M perchloric acid, the results are as follows image 3Shown, Pt 3 The oxygen reduction catalytic activity of Co / conductive carbon black is higher than that of commercial Pt / conductive carbon blac...

Embodiment 3

[0037] Preparation of PtFeCoNi / Conductive Carbon Ink Supported Catalyst

[0038] Step 1, get 1 gram of chloroplatinic acid hexahydrate [H 2 PtCl 6 ·6H 2 O], 0.780 grams of ferric nitrate nonahydrate [Fe(NO 3 ) 3 9H 2 O], 0.562 grams of cobalt nitrate hexahydrate [Co(NO 3 ) 2 ·6H 2 O], 0.561 grams of nickel nitrate hexahydrate [Ni(NO 3 ) 2 ·6H 2 O], dissolved in 150mL deionized water, ultrasonically dissolved for 10min, then added 2.846g of Vulcan XC-72R carbon black and 2.846g of PVP (average molecular weight 8000) and ultrasonically mixed for 20 minutes. The atomic molar ratio of platinum to iron, cobalt and nickel is 1:1:1:1, and the weight ratio of the sum of the weights of platinum, iron, cobalt and nickel to the conductive carbon black is 1:4.

[0039] Step 2, the mixed solution is sprayed and quickly dried to obtain a dry mixed powder: the fine mist is sprayed onto a quartz plate with a temperature of 250 ° C, and the aqueous solution is quickly evaporated to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com