Environment-friendly anti-formaldehyde acid and alkali resistant industrial coating

A formaldehyde resistance, acid and alkali resistance technology, applied in anti-corrosion coatings, coatings, etc., can solve the problems of inability to effectively remove formaldehyde for a long time and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

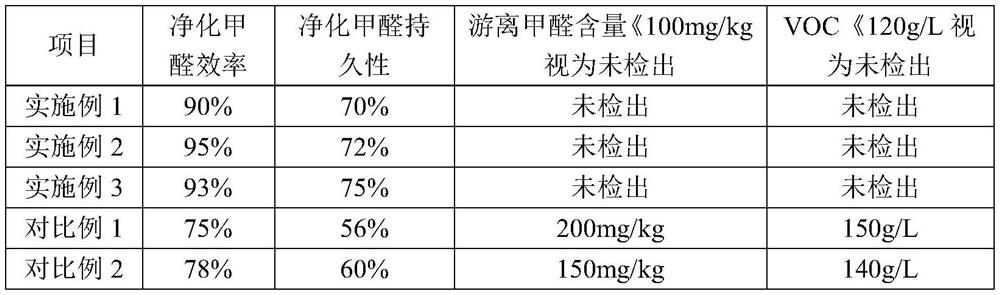

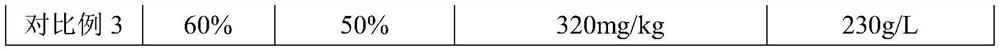

Examples

Embodiment 1

[0034] This embodiment provides an environmentally friendly formaldehyde-resistant acid and alkali resistant industrial coating, which includes: 10 parts of butyl acrylate, 10 parts of methyl acrylate, 20 parts of acrylic acid, chitosan-titanium dioxide-carbon nanotube composite 5 parts, 2 parts of diatomite, 1 part of nano bismuth oxychloride 0.5 parts of dispersant, 2 parts of film forming agent, 0.3 parts of wetting agent, 0.5 parts of defoaming agent, 0.5 parts of leveling agent, 1 part of adhesion promoter , 0.1 part of antifungal agent.

[0035] The above-mentioned environmentally friendly formaldehyde-resistant acid and alkali-resistant industrial coatings are prepared in the following manner:

[0036] Step 1: Mix 10 parts of butyl acrylate, 10 parts of methyl acrylate, 20 parts of acrylic acid, 0.5 parts of dispersant, 0.3 parts of wetting agent, 0.5 parts of defoamer, 0.5 parts of leveling agent, and 1 part of adhesion promoter , stirring for 1 to 2 hours at a rotati...

Embodiment 2

[0040] This embodiment provides an environmentally friendly formaldehyde-resistant acid and alkali-resistant industrial coating, which includes: 15 parts of butyl acrylate, 10 parts of methyl acrylate, 20 parts of acrylic acid, and 15 parts of 4-hydroxybutyl methacrylate. 15 parts of chitosan-titanium dioxide-carbon nanotube compound, 5 parts of diatomaceous earth, 2 parts of nano-bismuth oxychloride, 1 part of dispersant, 3 parts of film-forming agent, 0.5 part of wetting agent, 0.5 part of defoamer , 1 part of leveling agent, 2 parts of adhesion promoter, 0.5 part of antifungal agent.

[0041] The above-mentioned environmentally friendly formaldehyde-resistant acid and alkali-resistant industrial coatings are prepared in the following manner:

[0042] Step 1: Mix 15 parts of butyl acrylate, 10 parts of methyl acrylate, 20 parts of acrylic acid, 15 parts of 4-hydroxybutyl methacrylate, 1 part of dispersant, 0.5 part of wetting agent, 0.5 part of defoamer, 1 1 part of levelin...

Embodiment 3

[0046] This embodiment provides an environmentally friendly formaldehyde-resistant acid and alkali-resistant industrial coating, which includes: 20 parts of butyl acrylate, 10 parts of methyl acrylate, 20 parts of acrylic acid, chitosan-titanium dioxide-carbon nanotube composite 10 parts, 3 parts of diatomite, 1.5 parts of nano-bismuth oxychloride 1 part of dispersant, 0.6 parts of dispersant, 2 parts of film-forming agent, 0.3 part of wetting agent, 0.4 part of defoamer, 0.8 part of leveling agent, 1 part of accelerator, 0.4 part of antifungal agent.

[0047] The above-mentioned environmentally friendly formaldehyde-resistant acid and alkali-resistant industrial coatings are prepared in the following manner:

[0048] Step 1: Mix 20 parts of butyl acrylate, 10 parts of methyl acrylate, 20 parts of acrylic acid, 10 parts of 4-hydroxybutyl methacrylate, 0.6 parts of dispersant, 0.3 parts of wetting agent, 0.4 parts of defoamer, 0.8 1 part of leveling agent, 1 part of adhesion pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com