Sputtering apparatus

A sputtering device and sputtering technology, applied in the field of functional thin films and functional thin films, can solve problems such as easy peeling and poor film strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

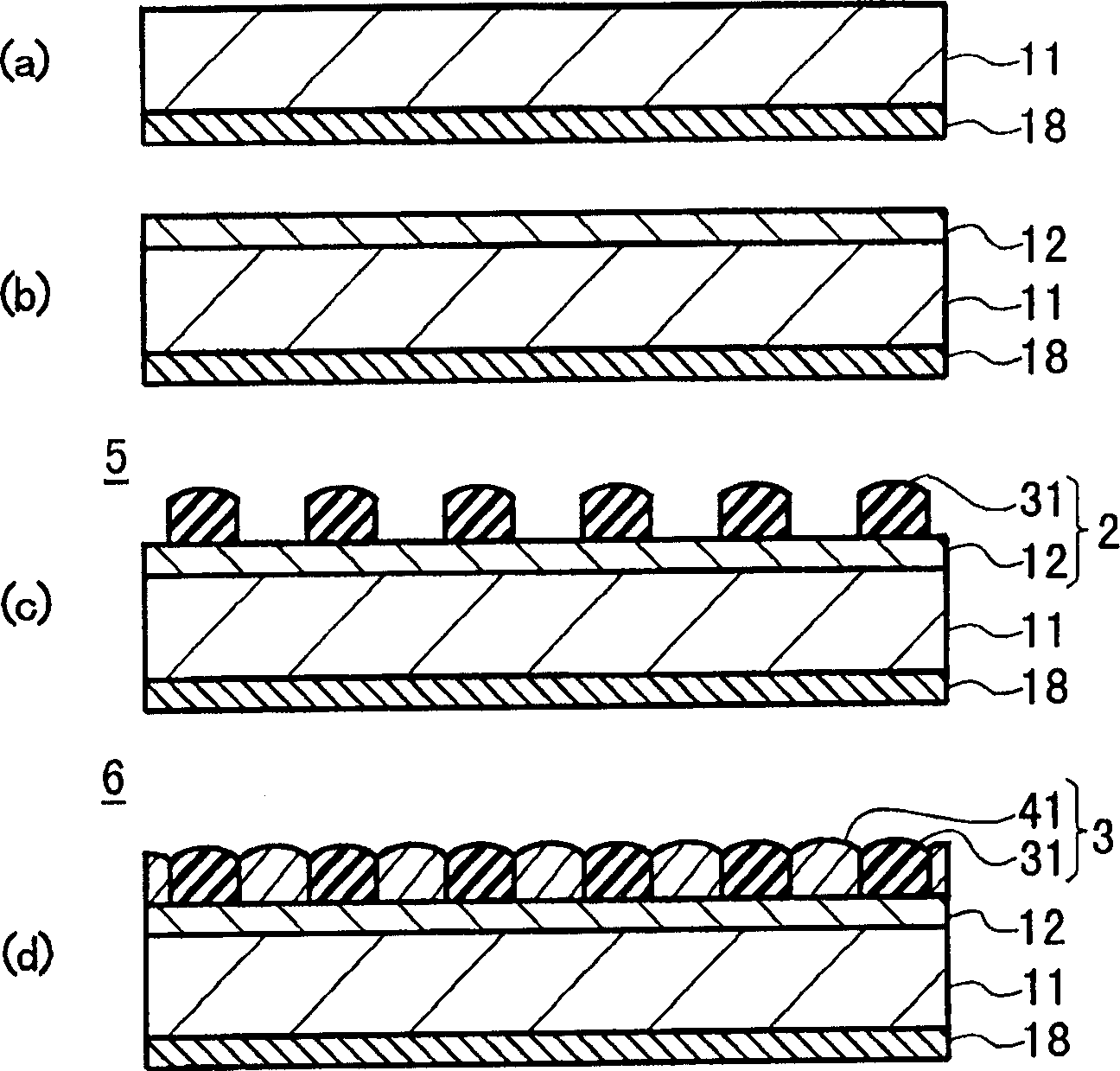

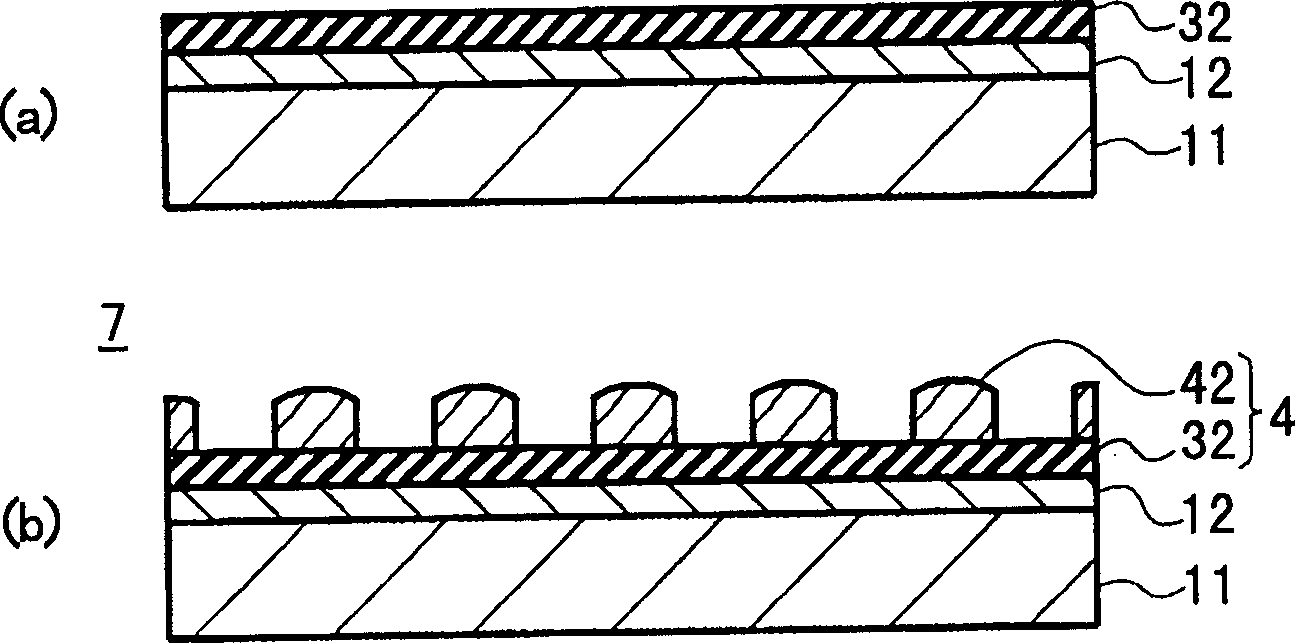

[0050] Preferred embodiments of the invention are described below

[0051] The functional thin film and functional substrate of the present invention will be described in detail, and the method for producing the titanium oxide thin film of the present invention will also be described.

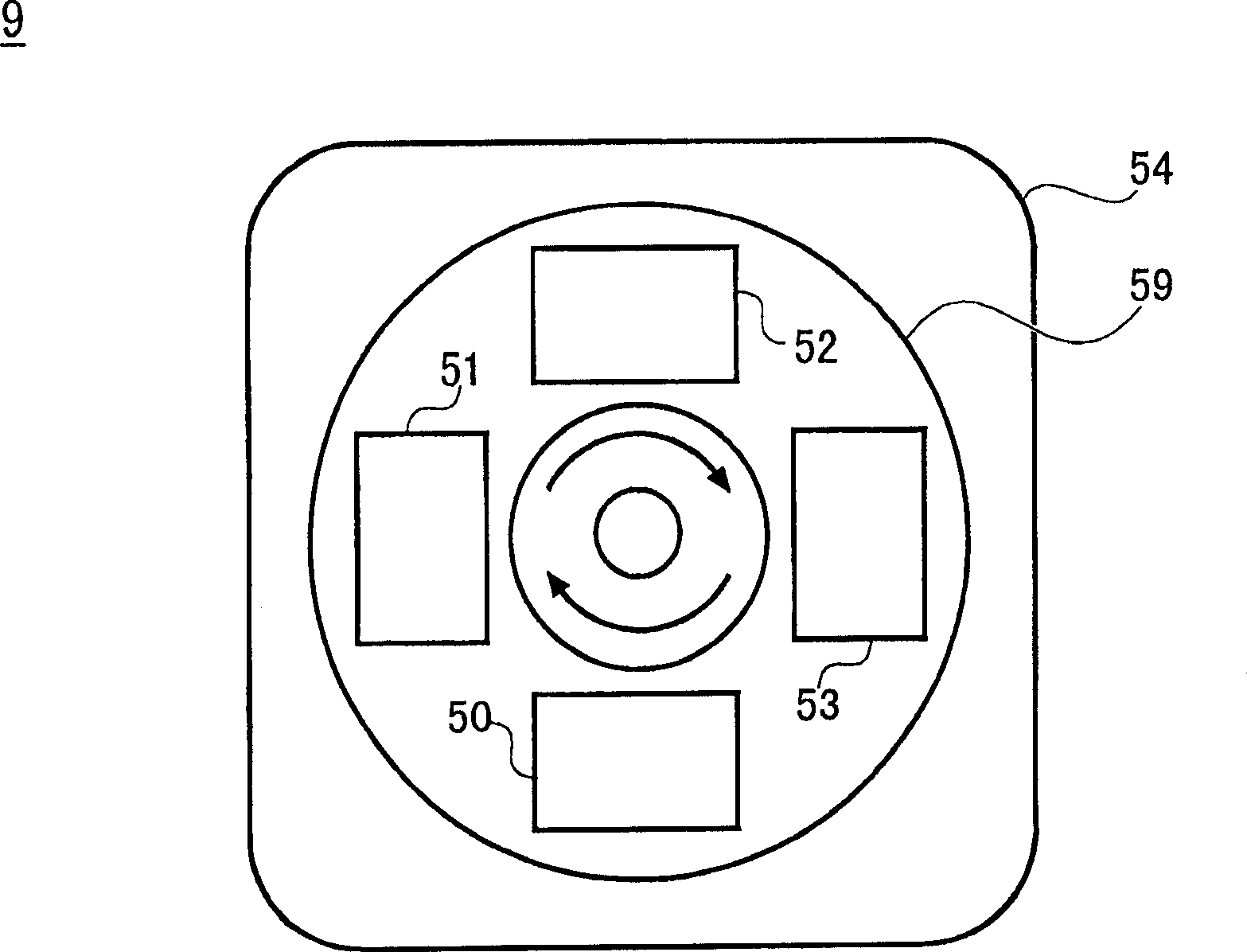

[0052] refer to image 3 , Reference numeral 9 is an example of a film forming apparatus for forming the functional thin film of the present invention. This film forming apparatus 9 has a vacuum chamber 54 . A turntable 59 is arranged on the bottom side in the vacuum chamber 54 , and a delivery unit 60 and the first to third film forming units 51 to 53 are arranged on the upper top thereof.

[0053] The turntable 59 can be rotated horizontally, and can also be moved up and down, and the substrate to be filmed can be sent into and out of the feeding part 60 from the delivery and delivery port not shown in the figure, and placed on the turntable 59, when the turntable is rotated At 59 o'clock,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com