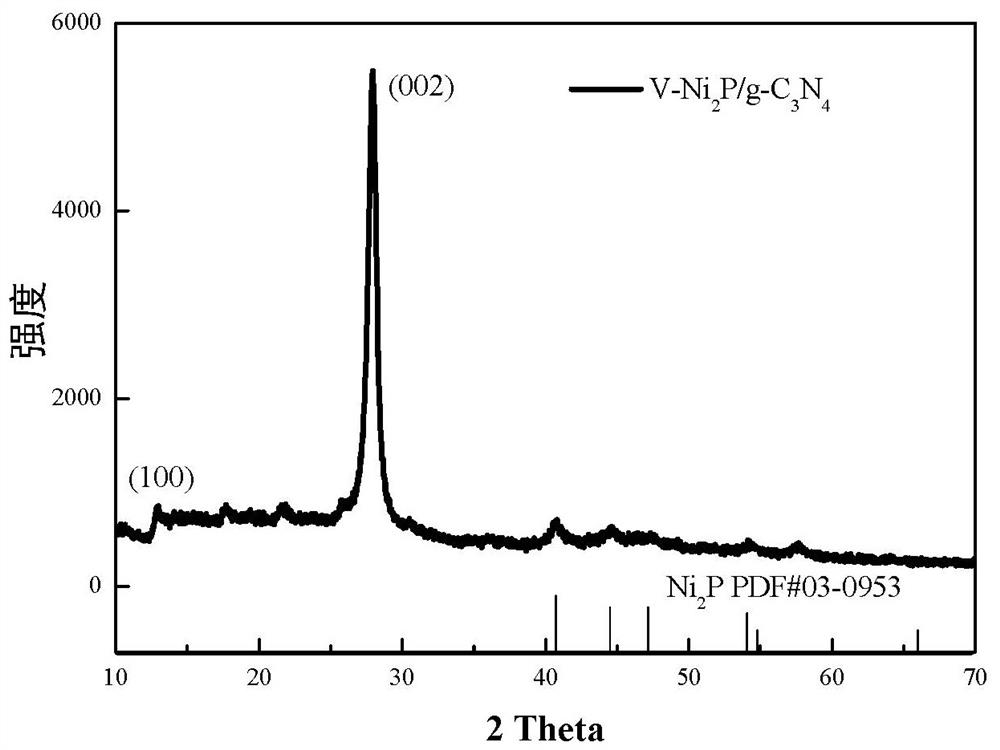

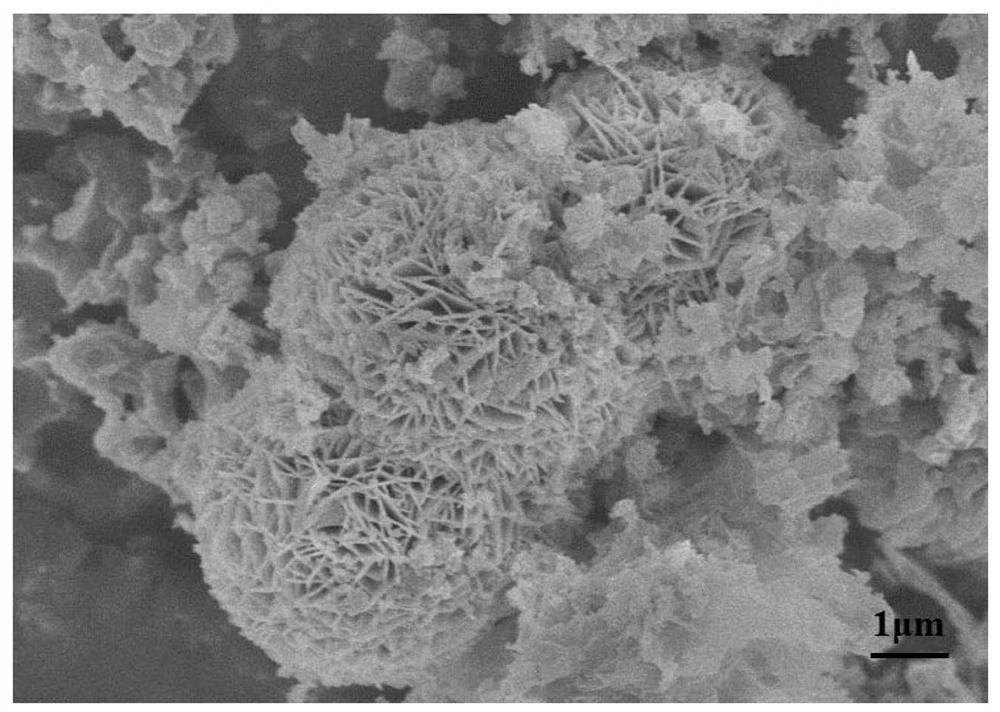

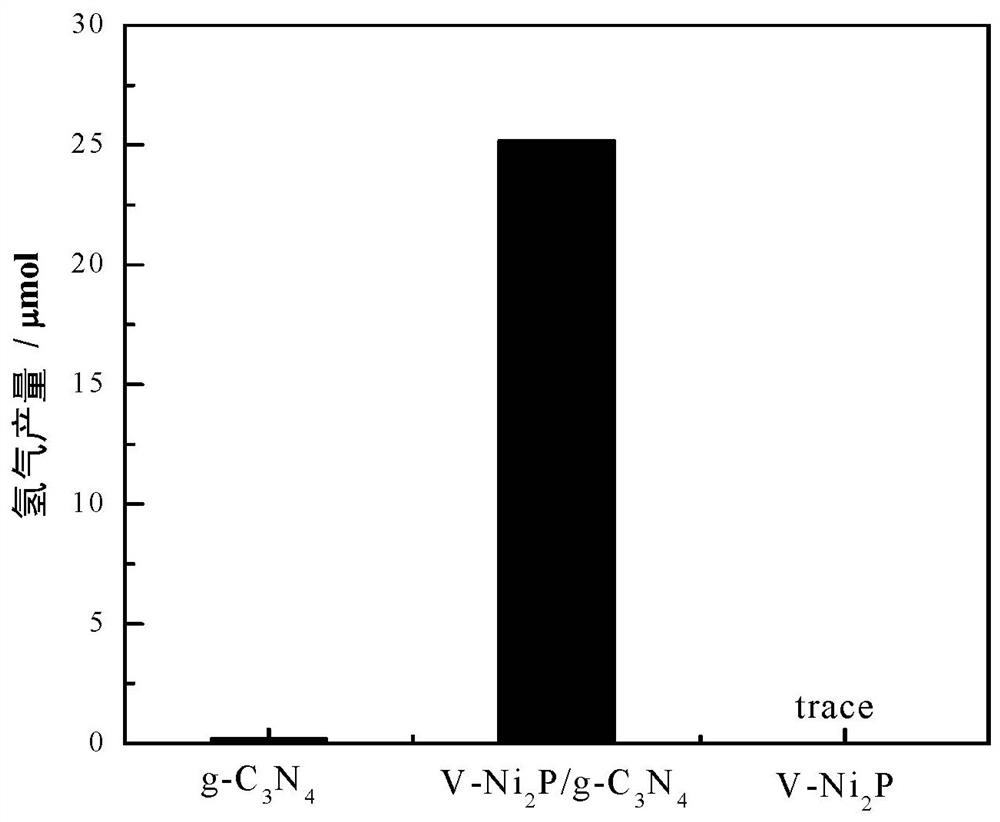

V-Ni2P/g-C3N4 photocatalyst as well as preparation method and application thereof

A photocatalyst, g-c3n4 technology, applied in the field of photocatalysis, achieves the effect of low production cost, easy control of conditions, and improved hydrogen production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] g-C 3 N 4 Preparation of the matrix. For example, g-C 3 N 4 It can be calcined in a muffle furnace. First, put 10g-15g of melamine into a porcelain boat, calcining at 450°C-600°C, holding time for 1h-5h, and heating rate at 2-10°C / min to obtain block g-C 3 N 4 . Then take out the sample and grind for 30min~60min, take 1g~5g block g-C 3 N 4 , add 100-200mLmL ethanol and sonicate for 5h-10h, then centrifuge and wash three times with deionized water, dry at 60°C-80°C for 6h-12h, take out and grind for later use.

[0038] The nickel chloride and the vanadium chloride are dissolved in water, and the pH value is adjusted to 3-5 with an acid solution to obtain a mixed solution A. Wherein, nickel chloride (nickel chloride hexahydrate) and vanadium chloride are compounded according to the following molar ratio, nickel chloride hexahydrate: vanadium chloride=(1~6):(1~3). Nickel chloride and vanadium chloride can also be prepared into solutions of different concentration...

Embodiment 1

[0048] (1) First, put 15g of melamine into a porcelain boat, calcine at 550°C, hold for 4 hours, and heat up at 2°C / min to obtain block g-C 3 N 4 , remove the sample and grind for 60 min. Take 1g block g-C 3 N 4 , add 100mL ethanol and sonicate for 6h, then centrifuge and wash three times with deionized water, dry at 60°C for 10h, take out and grind for later use;

[0049] (2) Add 10mL of 0.2mol / L nickel chloride hexahydrate solution and 10mL of 0.04mol / L vanadium chloride solution in a 50mL beaker, nickel chloride hexahydrate and vanadium chloride shall be proportioned according to the following molar ratio, hexahydrate Nickel chloride:vanadium chloride=5:1. Then add 0.005 mol / L hydrochloric acid solution to adjust the pH value to 4, and magnetically stir for 15 min to obtain a mixed solution A. Then pour the mixed solution A into one side of the two-chamber hydrothermal kettle;

[0050] (3) Add 20mL deionized water and 10mL ethylene glycol into a 100mL beaker, then add...

Embodiment 2

[0060] (1) First, put 10 g of melamine into a porcelain boat, calcine at a temperature of 550°C, hold for 3 hours, and heat up at a rate of 5°C / min to obtain block g-C 3 N 4 . Take out the sample and grind it for 60min, take 2g block g-C 3 N 4 , add 200mLmL ethanol and sonicate for 10h, then centrifuge and wash three times with deionized water, dry at 80°C for 12h, take out and grind for later use;

[0061] (2) Add 5mL of 0.4mol / L nickel chloride hexahydrate solution and 15mL of 0.034mol / L vanadium chloride solution in a 50mL beaker, nickel chloride hexahydrate and vanadium chloride shall be proportioned according to the following molar ratios, hexahydrate Nickel chloride:vanadium chloride=4:1, then add 0.008mol / L hydrochloric acid solution to adjust the pH value to 5, and magnetically stir for 20min to obtain mixed solution A. Then pour the mixed solution A into one side of the two-chamber hydrothermal kettle;

[0062] (3) Add 30mL deionized water and 20mL ethylene glyco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com