A kind of thermoplastic composite film and its production process

A production process and technology of composite film, applied in the field of composite film, can solve the problems of poor thermoplasticity of polypropylene composite film, aging of polypropylene composite film, etc., and achieve the effect of solving the problem of no thermoplasticity, excellent toughness and good mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

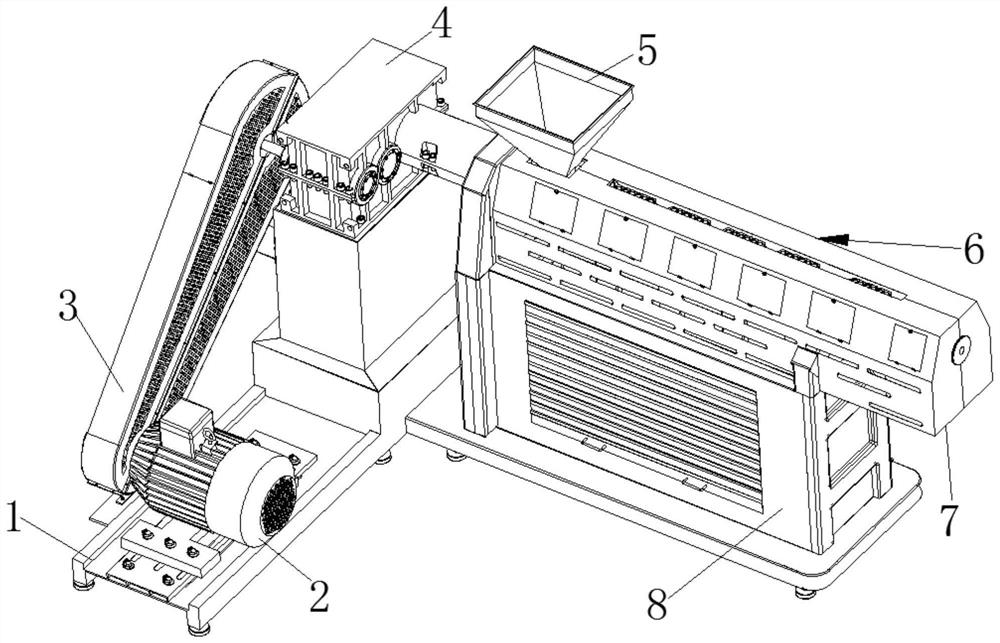

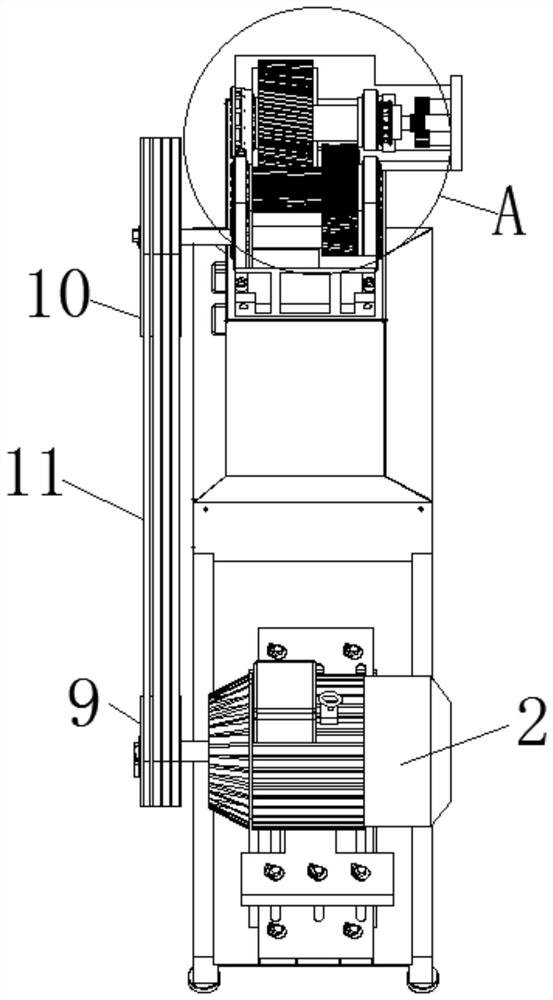

Image

Examples

preparation example Construction

[0033] The preparation technology of modified polypropylene layer comprises the following steps:

[0034] Step 1: Put the high-density polyethylene in a vacuum drying oven with a temperature of 60-65°C and dry it for 60-90min, place the polypropylene in a vacuum oven with a temperature of 80-85°C, and dry it for 120- 150min, cooling, then the high-density polyethylene that is 15-25 parts by weight and the polypropylene that parts by weight are 75-85 mix homogeneously, pour into the feed inlet 5 of twin-screw extruder;

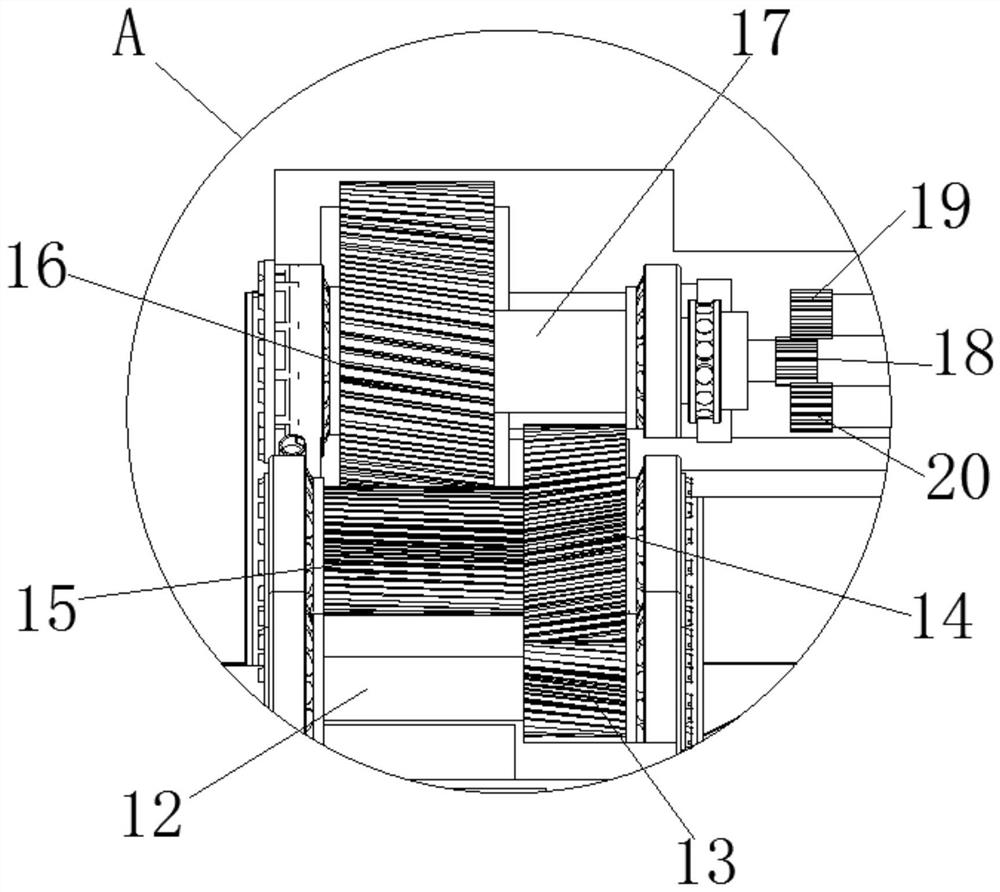

[0035] Step 2: start the first heating chip 23, the second heating chip 24, the third heating chip 25, the fourth heating chip 26, the fifth heating chip 27 and the sixth heating chip 28, thereby preheating the extruding tube 30, the first The heating temperature of the heating sheet 23 is 170-175°C, the heating temperature of the second heating sheet 24 is 180-185°C, the heating temperature of the third heating sheet 25 is 188-192°C, and the heating temperatur...

Embodiment 1

[0047] A thermoplastic composite film, the thermoplastic composite film sequentially comprises a nanoscale titanium dioxide layer, a polyethylene terephthalate layer, a modified polypropylene layer, and a polyethylene terephthalate layer from outside to inside and the nanoscale titanium dioxide layer, the thickness of the two nanoscale nanoscale titanium dioxide layers is 11 μm, the thickness of the two polyethylene terephthalate layers is 16 μm, and the thickness of the modified polypropylene layer is 30 μm, the modified polypropylene layer is obtained by casting modified polypropylene through a casting machine, and the modified polypropylene is obtained by mixing high-density polyethylene with 20 parts by weight and polypropylene with 80 parts by weight Obtained after melt blending and extruding through a twin-screw extruder;

[0048] The preparation technology of modified polypropylene layer comprises the following steps:

[0049] Step 1: Place the high-density polyethylen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com