A kind of transparent pm2.5 filter film with photocatalysis and preparation method thereof

A filter membrane and photocatalysis technology, applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, separation methods, etc., can solve the problem of single function, poor air permeability, low light transmittance of air filter membrane, etc. problems, to achieve high-efficiency filtration performance, stable performance, and good lighting effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

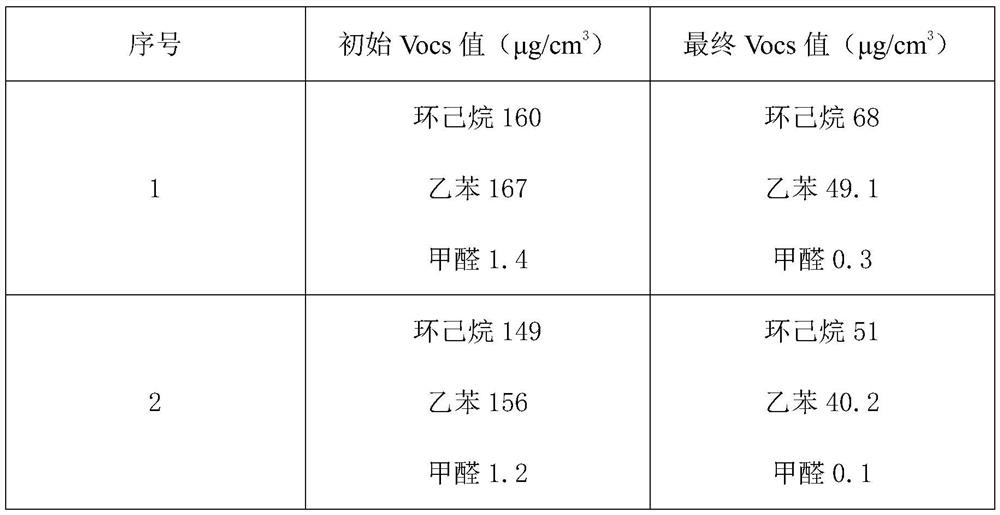

Examples

Embodiment 1

[0044] S1, spinning solution preparation

[0045] Weigh respectively the polyacrylonitrile powder (PAN) of 3g, the nanometer titanium dioxide powder (TiO2) of 0.6g 2 ), 47g N,N-dimethylformamide (DMF), slowly add PAN powder into the DMF solution, stir magnetically at 25°C for 8h, and then add nano-TiO 2 Slowly add to the solution, continue stirring at 25°C for 8h, and prepare PAN@TiO with a mass fraction of 6%. 2 Spinning solution: Weigh 6g of polyamide-6 particles (PA6) and dissolve them in 44g of formic acid solution, stir magnetically at 25°C for 18 hours until the PA6 particles are completely dissolved, and prepare a PA6 spinning solution with a mass percentage of 12%, which is set aside.

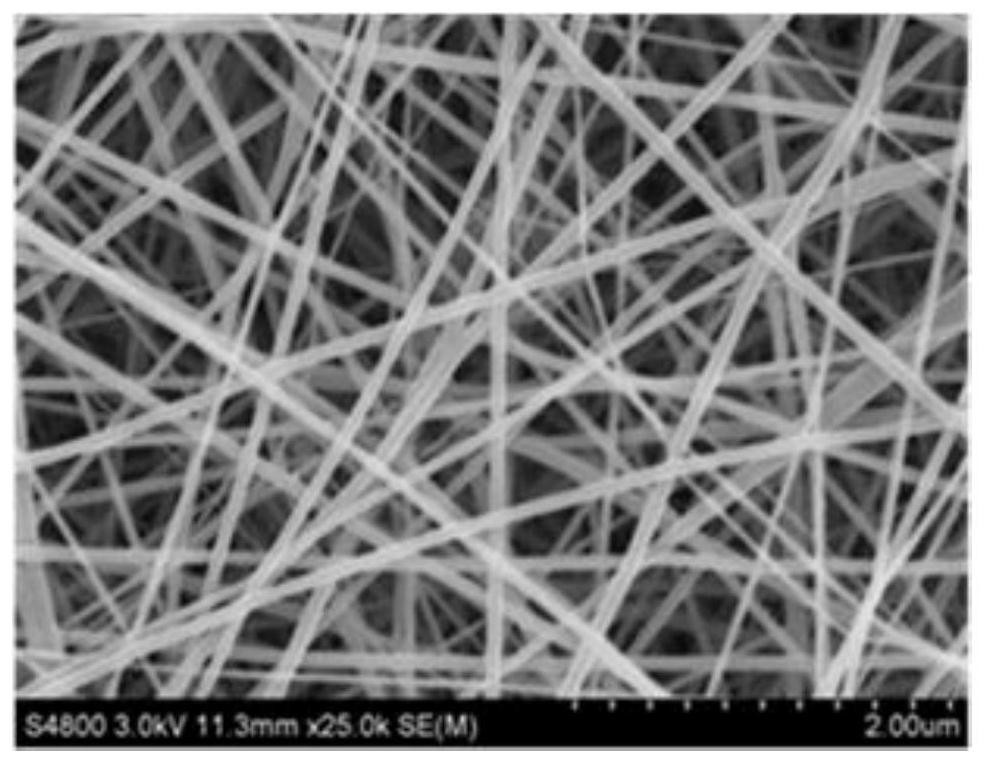

[0046] S2, PAN@TiO 2 / PA6 composite nanofiber preparation

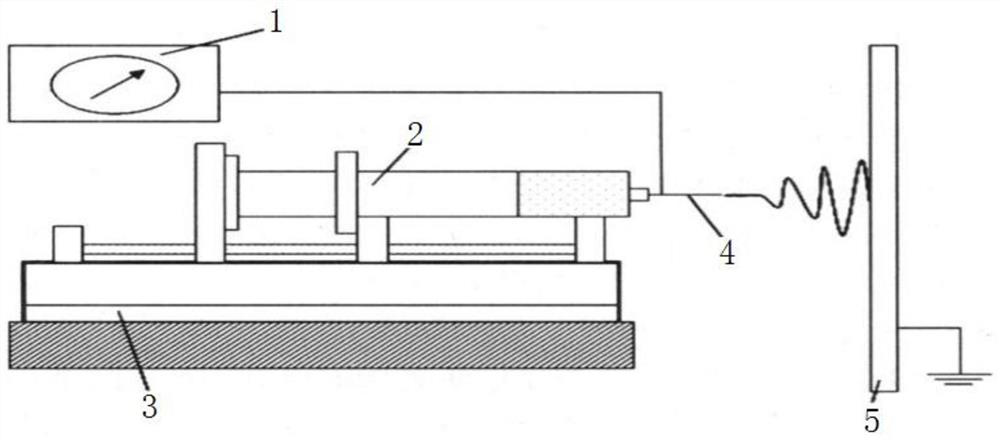

[0047] The above PAN@TiO 2 Spinning solution and PA6 spinning solution are respectively injected into the two liquid storage cylinders of syringe 2 in micro-injection pump 3, tinfoil paper is placed on receiving device 5, s...

Embodiment 2

[0053] S1, spinning solution preparation

[0054] Weigh respectively the polyacrylonitrile powder (PAN) of 4g, the nano titanium dioxide powder (TiO2) of 0.8g 2 ), 46g N,N-dimethylformamide (DMF). Slowly add PAN powder into the DMF solution, stir magnetically at 25°C for 12h, and then add nano-TiO 2 Slowly add to the solution, continue stirring at 25°C for 12h, and prepare PAN@TiO with a mass fraction of 8% 2 Spinning solution: Weigh 7g of polyamide-6 particles (PA6) and dissolve them in 43g of formic acid solution, stir magnetically at 25°C for 24h until the PA6 particles are completely dissolved, and prepare a PA6 spinning solution with a mass percentage of 14%.

[0055] S2, PAN@TiO 2 / PA6 composite nanofiber preparation

[0056] The above PAN@TiO 2 Spinning solution and PA6 spinning solution are respectively injected into the two liquid storage cylinders of syringe 2 in micro-injection pump 3, tinfoil paper is placed on receiving device 5, start high-voltage power supp...

Embodiment 3

[0062] S1, spinning solution preparation

[0063] Take respectively the polyacrylonitrile powder (PAN) of 5g, the nano titanium dioxide powder (TiO2) of 1g 2 ), 45g N,N-dimethylformamide (DMF). Slowly add PAN powder into the DMF solution, stir magnetically at 25°C for 12h, and then add nano-TiO 2 Slowly add to the solution, continue to stir at 25°C for 12h, and prepare a PAN@TiO2 spinning solution with a mass fraction of 10%; weigh 8g of polyamide-6 particles (PA6) and dissolve it in 42g of formic acid solution, and stir magnetically at 25°C for 24h Until the PA6 particles are completely dissolved, a PA6 spinning solution with a mass percentage of 16% is prepared.

[0064] S2, PAN@TiO 2 / PA6 composite nanofiber preparation

[0065] The above PAN@TiO 2 and polyamide-6 spinning solution are respectively injected into the two liquid storage cylinders of the syringe 2 in the micro-injection pump 3, the tinfoil paper is placed on the receiving device 5, the high-voltage power ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com