Preparation method of PAN-based oil-water separation microporous membrane with photocatalysis function

A technology of oil-water separation and microporous membrane, which is applied in the field of membrane materials, can solve the problems of poor porosity, poor permeability, and low specific surface area of membrane materials, and achieve high porosity, high loading rate, and large specific surface area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The invention provides a kind of preparation method (abbreviation method) of the PAN-based oil-water separation microporous membrane with photocatalytic function, it is characterized in that the method comprises the following steps:

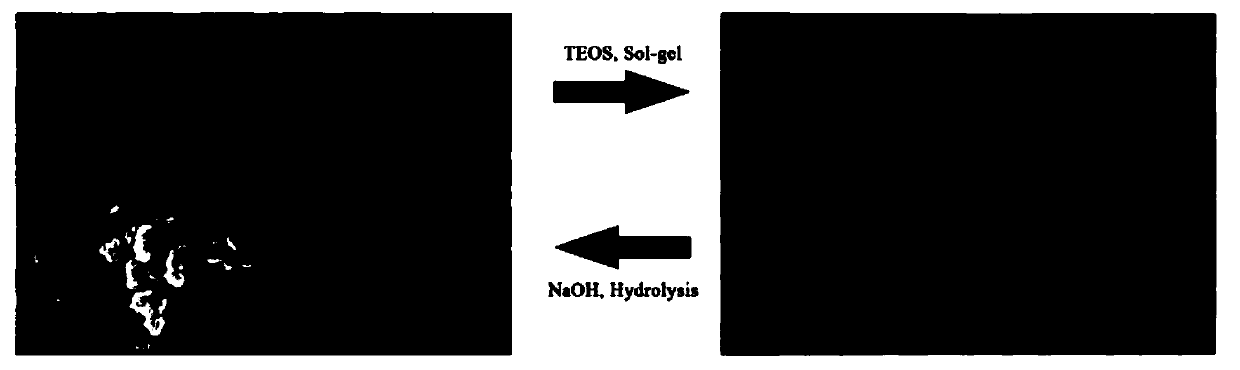

[0025] 1)SiO2 2 @TiO 2 Preparation of additives: at room temperature (10-35°C), add TiO 2 The particles are dispersed evenly in ethanol by ultrasonic, and ammonia water and deionized water are added at the same time to obtain TiO 2 Mixed solution; ammonia and TiO 2 The mass ratio of particles is 3 to 5:1; deionized water and TiO 2 The mass ratio of particles is 60:1; TiO 2 Ethanol and TiO in the mixture 2 The mass ratio of particles is 100:0.5;

[0026] Dissolve TEOS (tetraethyl orthosilicate) in ethanol to obtain TEOS solution; TEOS and TiO 2 The mass ratio of particles is 2-4:1; the mass ratio of ethanol to TEOS in TEOS solution is 100:5;

[0027] TiO 2 Move the mixed solution into an environment (water bath) at 25-35°C, add TEO...

Embodiment 1

[0038] (1) Preparation of SiO by sol-gel method 2 @TiO 2 Additive: 150mg of TiO 2 Add 40mL ethanol to ultrasonic dispersion for 2h, add 15mL ammonia water and 10mL deionized water; dissolve 4.3mL tetraethyl orthosilicate in 20mL ethanol; 2 The mixed solution was transferred to a hydrothermal kettle for constant temperature reaction for 2 hours. During the reaction, the TEOS solution was gradually added dropwise. The reaction temperature was 25-35°C. Then the product was washed with ethanol and deionized water until it was neutral, and finally dried at 60°C. Get SiO 2 @TiO 2 additive;

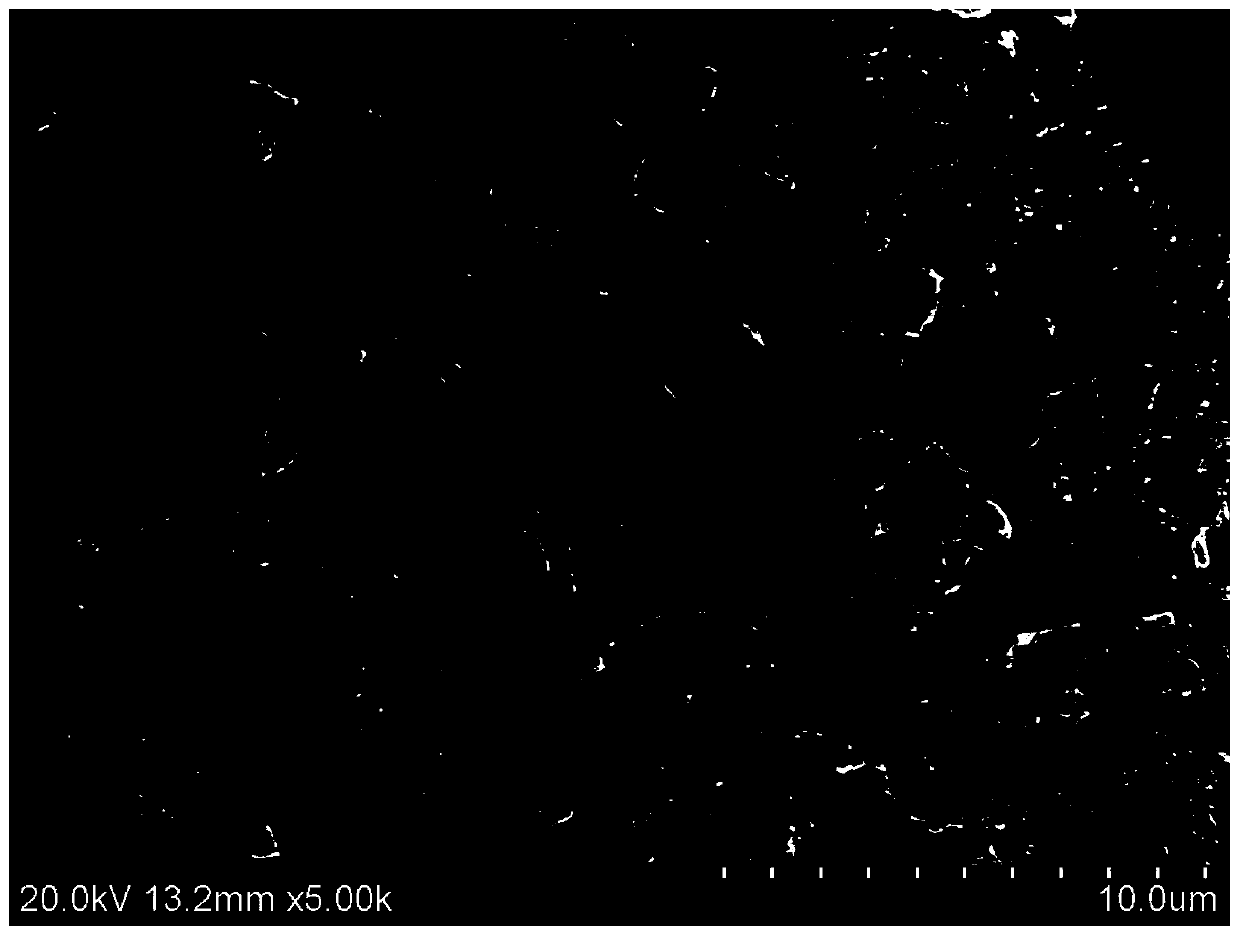

[0039] (2) Contains SiO 2 @TiO 2 The preparation of the P(AN-MA) microporous membrane of the additive: 5.1g caprolactam, 5.1g triacetin, 1.8g polyacrylonitrile methyl acrylate and 0.1g above-mentioned SiO 2 @TiO 2 The additive was added to a 100mL flask, ultrasonically dispersed in a water bath for 90 minutes to obtain a uniform mixed solution, heated and stirred for 90 minutes under the...

Embodiment 3

[0062] (1) Preparation of SiO by sol-gel method 2 @TiO 2 Additive: 150mg of TiO 2 Add 40mL ethanol to ultrasonic dispersion for 2h, add 15mL ammonia water and 10mL deionized water; dissolve 4.3mL tetraethyl orthosilicate in 20mL ethanol; 2 The mixed solution was transferred into a hydrothermal kettle for constant temperature reaction for 3 hours. During the reaction, the TEOS solution was gradually added dropwise. The reaction temperature was 25-35°C. Then the product was washed with ethanol and deionized water until neutral, and finally dried at 60°C. Get SiO 2 @TiO 2 additive;

[0063] (2) Contains SiO 2 @TiO 2 The preparation of the P(AN-MA) microporous membrane of the additive: 4.7g caprolactam, 4.7g glycerol triacetate, 2.4g polyacrylonitrile methyl acrylate and 0.1g above-mentioned SiO 2 @TiO 2 Add the additive into a 100mL flask, and then ultrasonically disperse it in a water bath ultrasonic for 95min to obtain a uniform mixed solution, heat and stir for 90min u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com